Flow control device for tundish in special-shaped billet continuous casting machine

A special-shaped billet continuous casting and tundish technology, which is applied to casting equipment, casting molten material containers, manufacturing tools, etc., can solve problems such as loss, and achieve prolonging service life, reducing excess injection, reducing breakouts and casting slabs The effect of quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

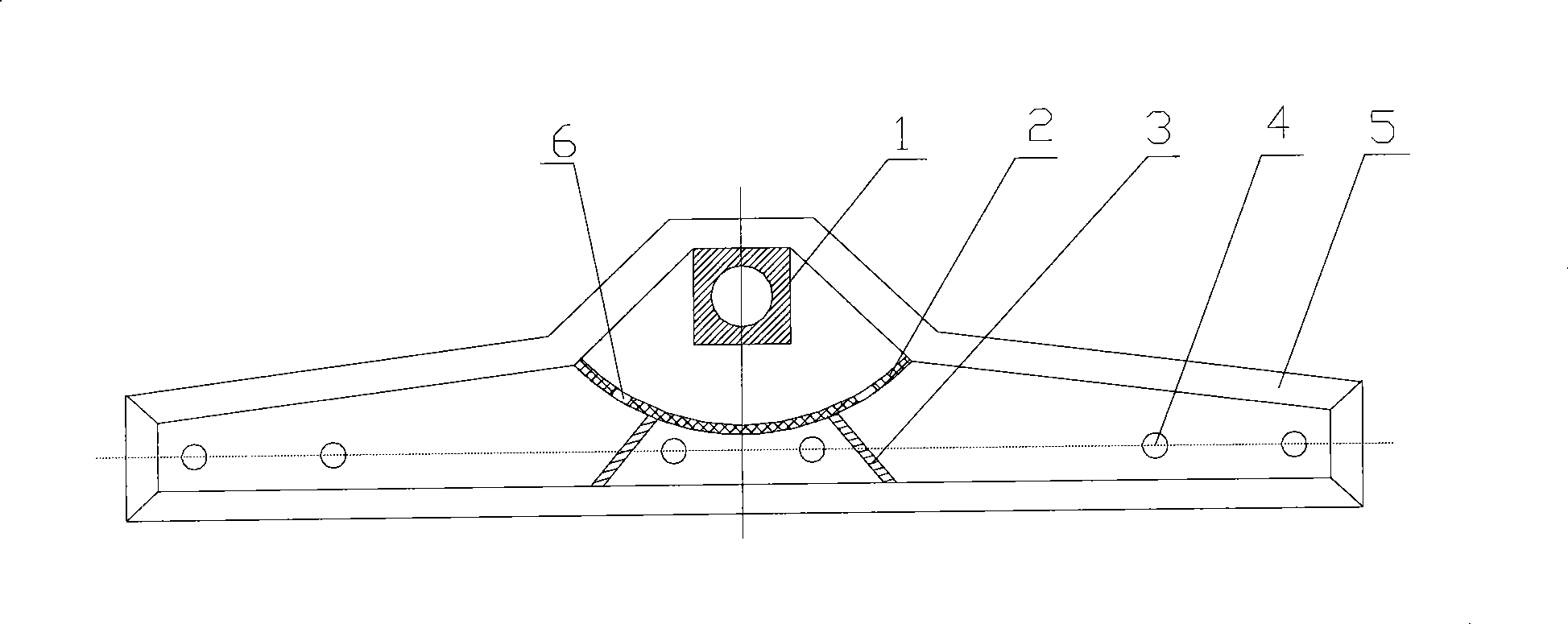

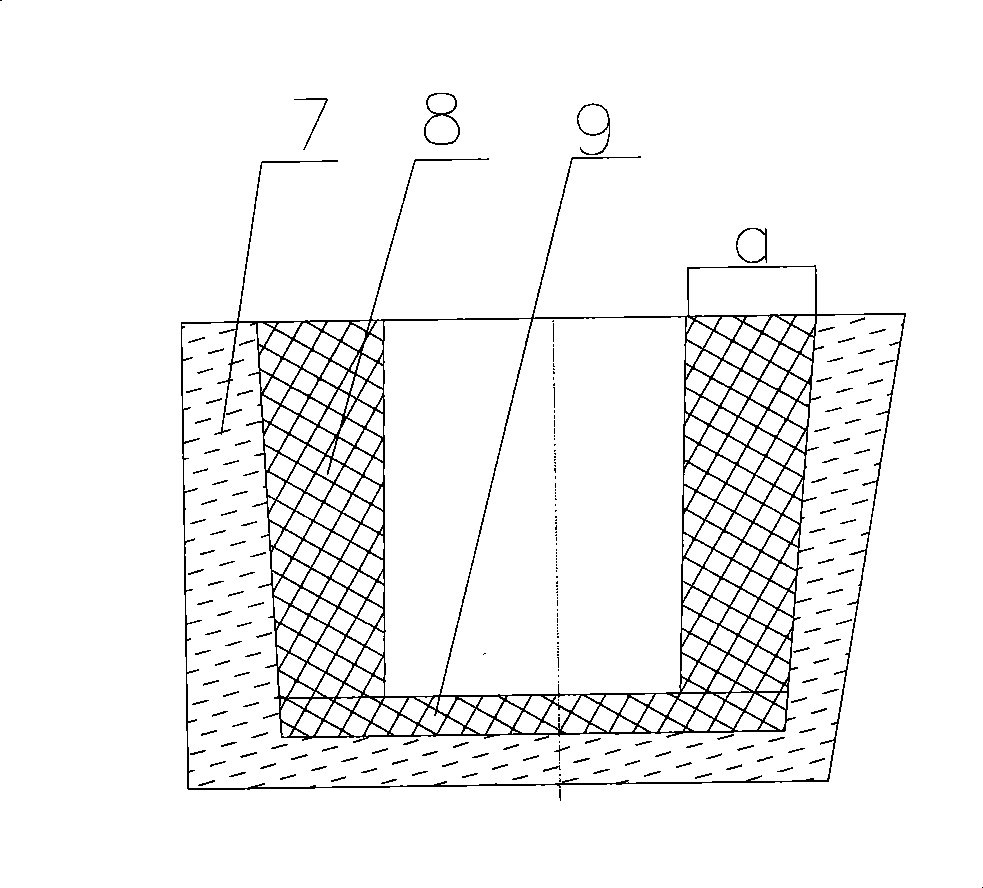

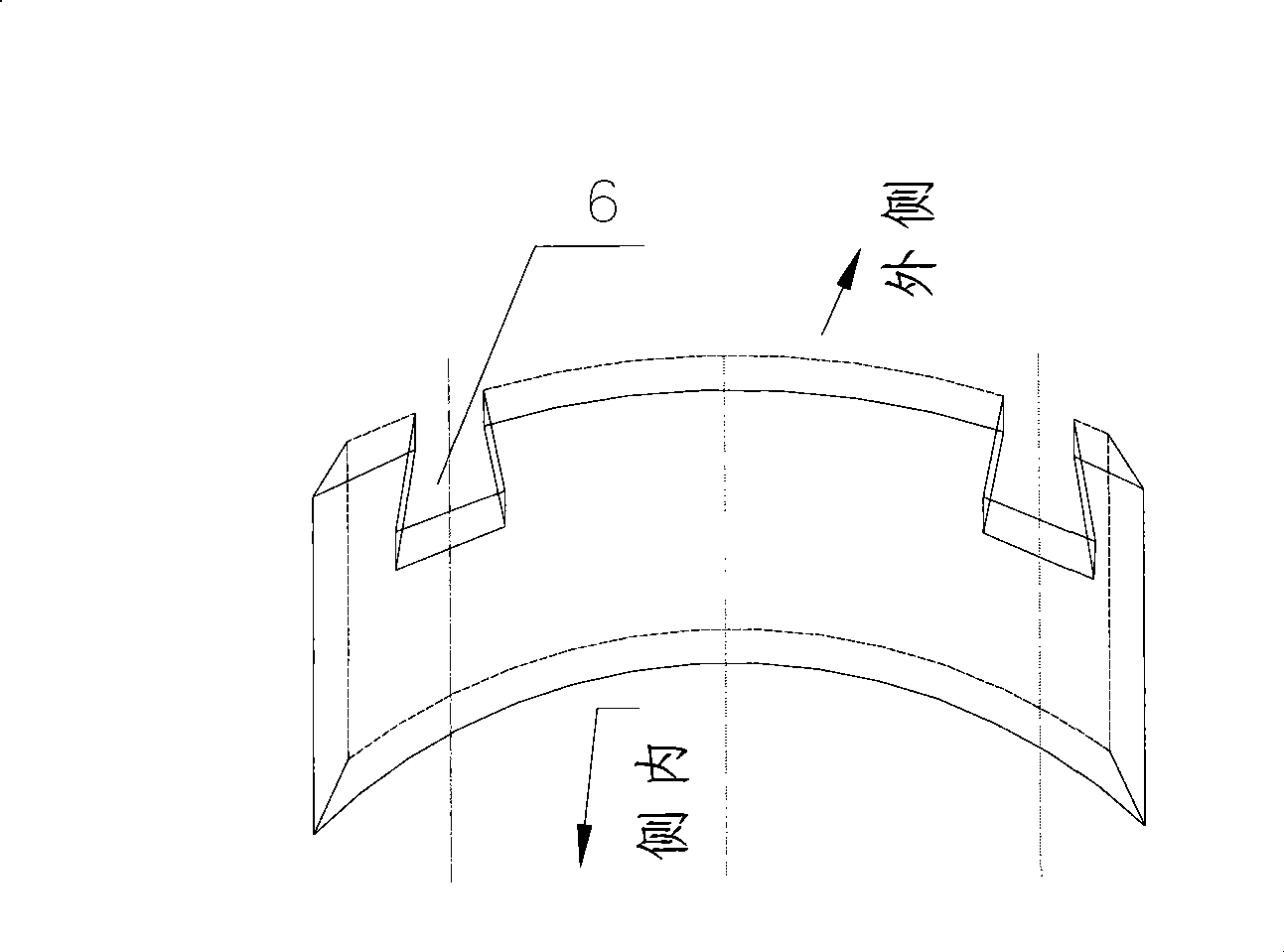

[0032] A tundish flow control device for a profiled billet continuous casting machine, comprising a flow stabilizer 1, a flow deflector 2, and a slag retaining dam 3, the flow stabilizer 1 is installed on the inner side of the working lining 5 of the tundish wall in the injection flow impact area of the tundish, and the middle The sizing nozzle 4 is installed on the center line of the working lining 5 at the bottom of the bag, and the deflector 2 is installed on the outside of the flow stabilizer 1. The deflector 2 is an arc-shaped structure, and the two sides of the deflector 2 are provided with trapezoidal grooves 6. Between the trapezoidal groove 6 of the deflector 2 and the sizing nozzle 4, a slag retaining dam 3 is respectively installed.

[0033] The current stabilizer adopts a set-type composite material structure, and its preparation method is divided into the following steps:

[0034] 1) The shell of the current stabilizer is designed according to the shape and size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com