Non-linearity electro-magnetism vibrating variable frequency hair-dressing hairclipper

An electromagnetic vibration and nonlinear technology, which is applied in metal processing and other directions, can solve the problems of unstable electromagnetic vibration structure, excessive heat generation of iron core wire package, and high production cost, so as to simplify product assembly process, reduce production cost and improve product quality. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

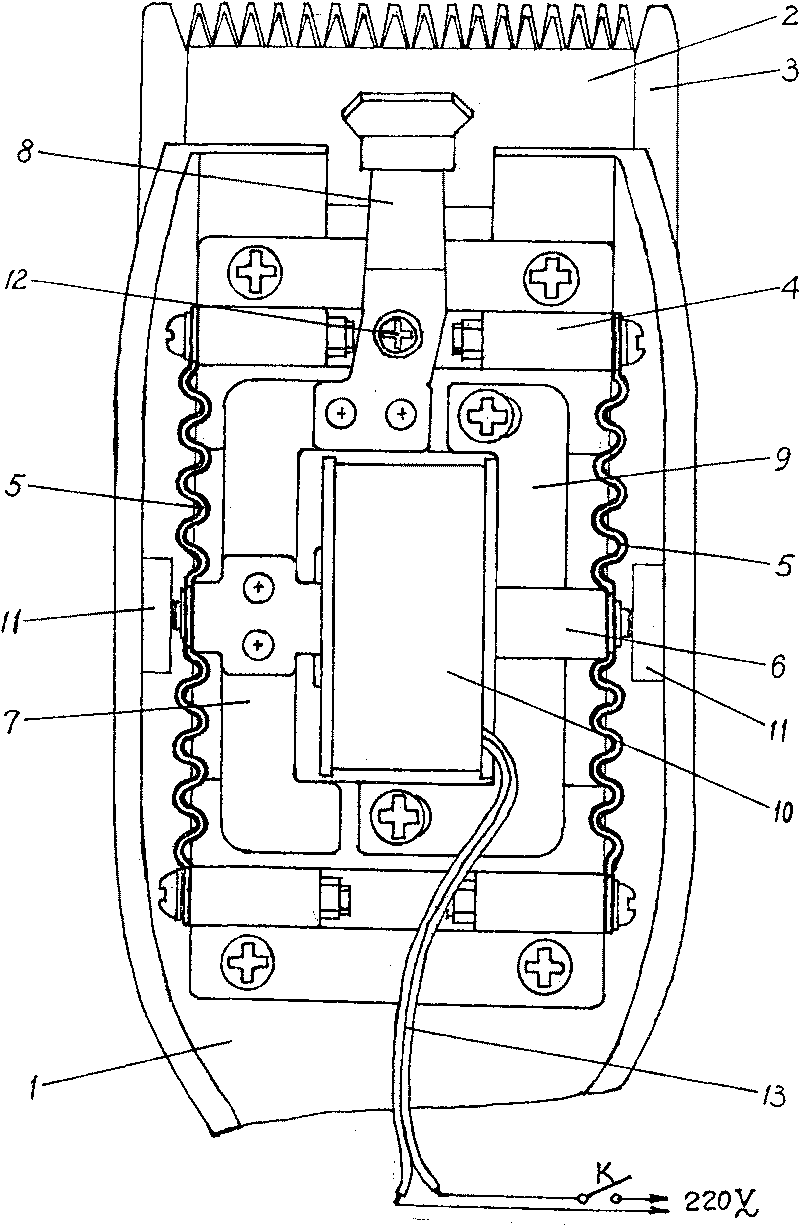

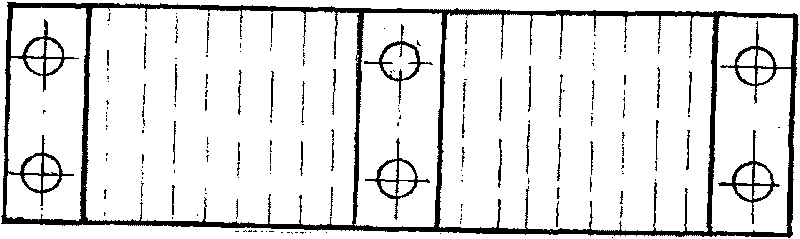

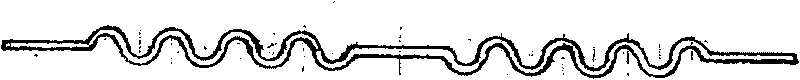

[0026] see Figure 1 to Figure 5 , the present invention is a kind of nonlinear electromagnetic vibration frequency conversion hair clipper, which is mainly connected by a casing 1, an upper blade part 2, a lower blade part 3, an iron core wire package part, a frame 4, a corrugated plate spring 5, and a main vibration part Plate 6, armature 7 and pressure reed 8 with insulating head and other components.

[0027] The lower blade part 3 is fixed on the casing 1 , and the upper blade part 2 is pressed on the lower blade part 3 . The frame 4 is arranged in the casing 1, and the frame 4 is installed in the casing 1 by fastening screws. The sectioned wave plate spring 5 is installed on the frame 4 side, the armature 7 is arranged in the frame 4, and the compression reed 8 with the insulating head is installed on the frame 4 front.

[0028] The core wire package part is composed of an iron core 9 and a wire package 10 , and the iron core wire package part is arranged in the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com