Wastewater treating and recycling process

A technology for waste water and production waste water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

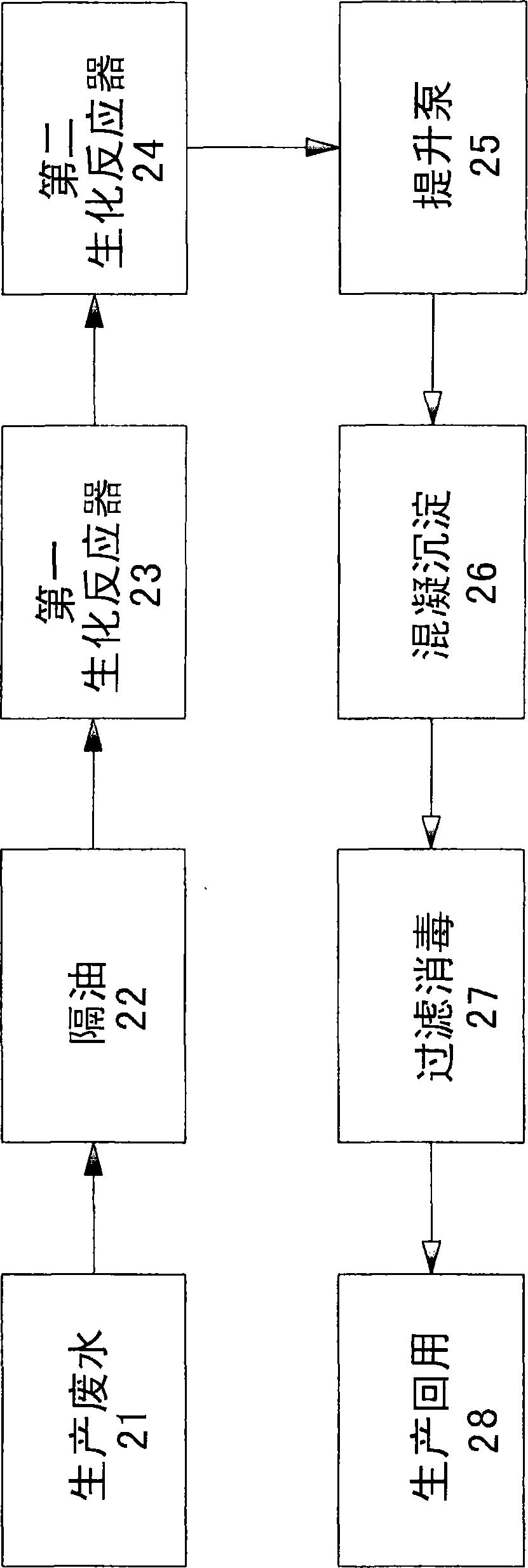

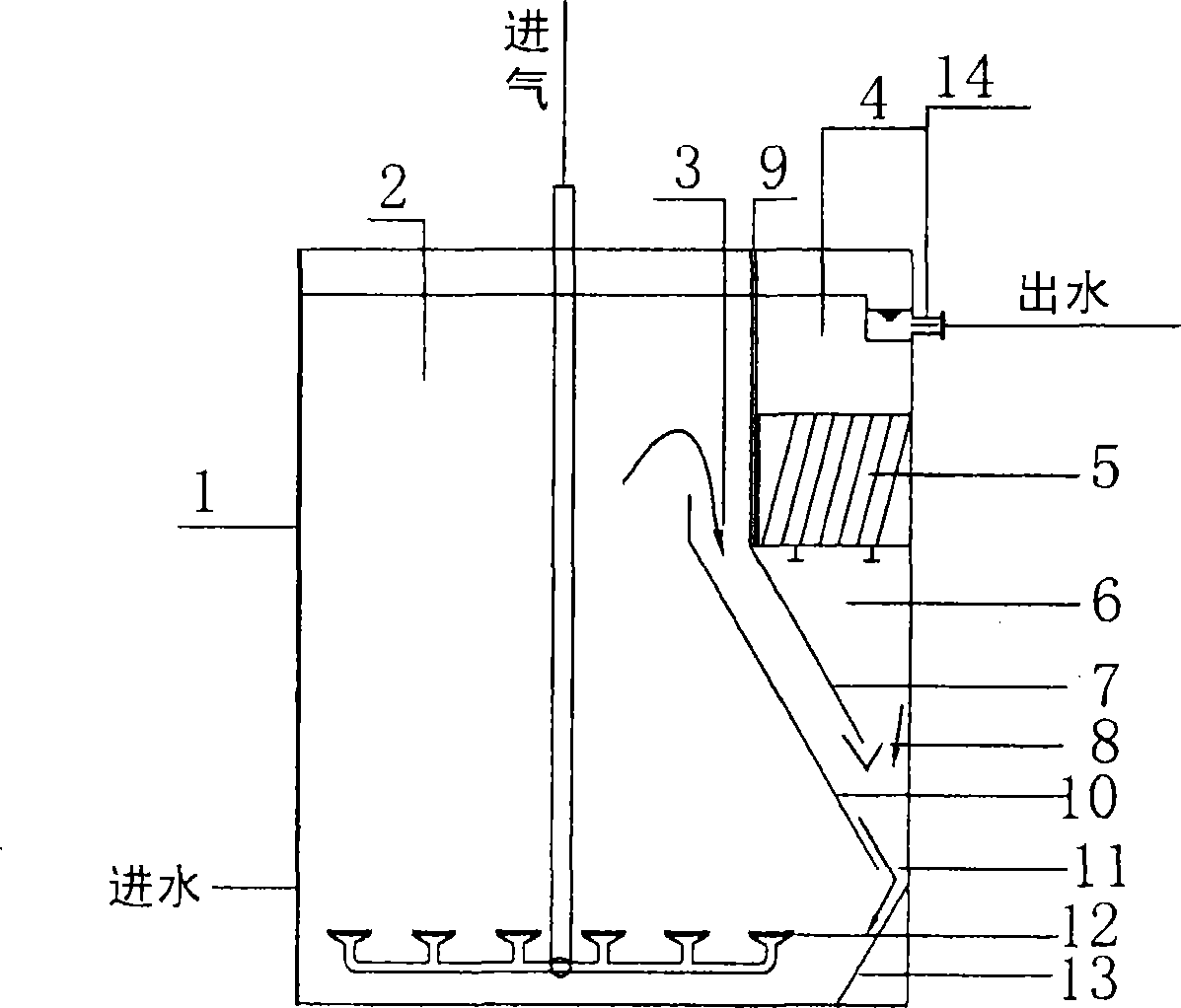

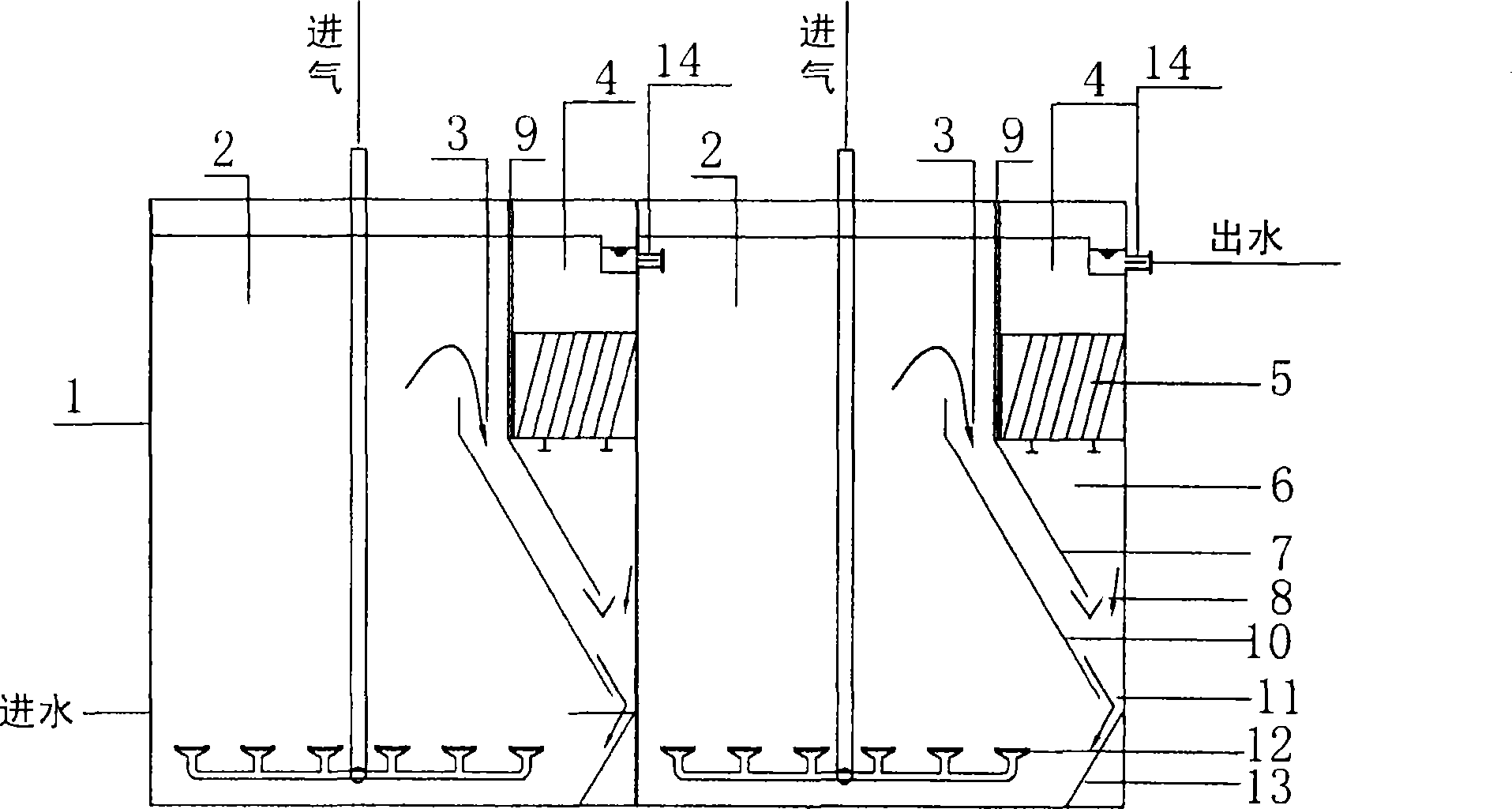

[0027] see figure 1 , the technological process of the present invention is: the production wastewater 21 first enters the grease trap 22 to remove some oil-like by-reaction products, and protects the subsequent biochemical treatment system. The wastewater enters the first biochemical reactor 23 by gravity, and utilizes the first biochemical reaction The high-concentration activated sludge in device 23 removes most of the organic matter. Due to the large amount of sludge, it has strong impact resistance to raw water. The self-circulating sludge has better activity and higher sludge load. The effluent treated by the first biochemical reactor 23 enters the second biochemical reactor 24 by gravity. In this second biochemical reactor 24, the microorganisms on its activated sludge or biological carrier (such as: biologically activated carbon, fly ash, etc.) are in an oligotrophic state, and the sludge load is lower than that of the previous section, and the sludge settling performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com