Press-key manufacturing method and apparatus thereof

A manufacturing method and key technology, applied in electrical components, electrical switches, circuits, etc., can solve the problems of non-compliance with manufacturing economic benefits, unsatisfactory manufacturing method process design, and poor production efficiency, so as to improve manufacturing economic benefits and products. Competitiveness, beneficial to mass production operations, and the effect of reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

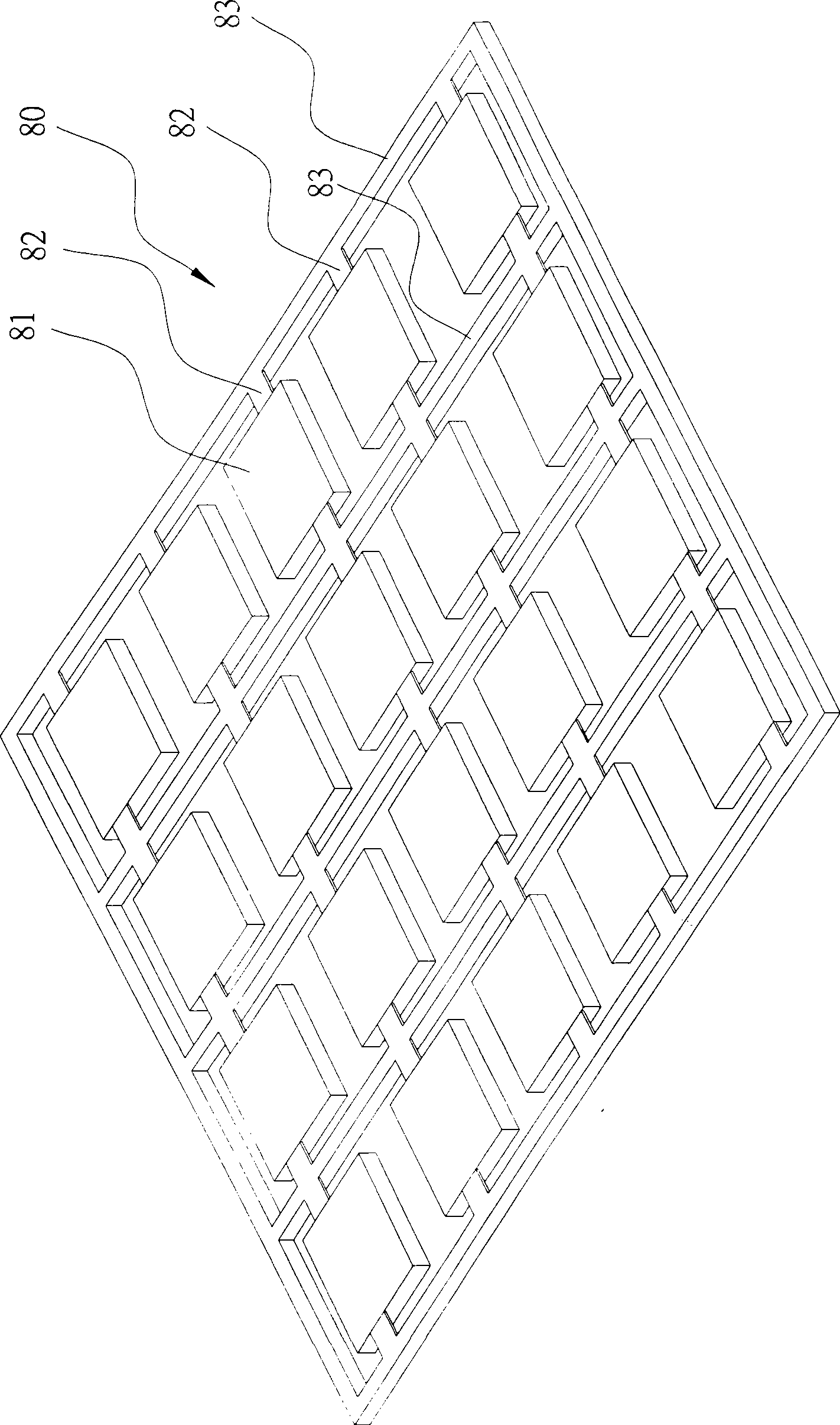

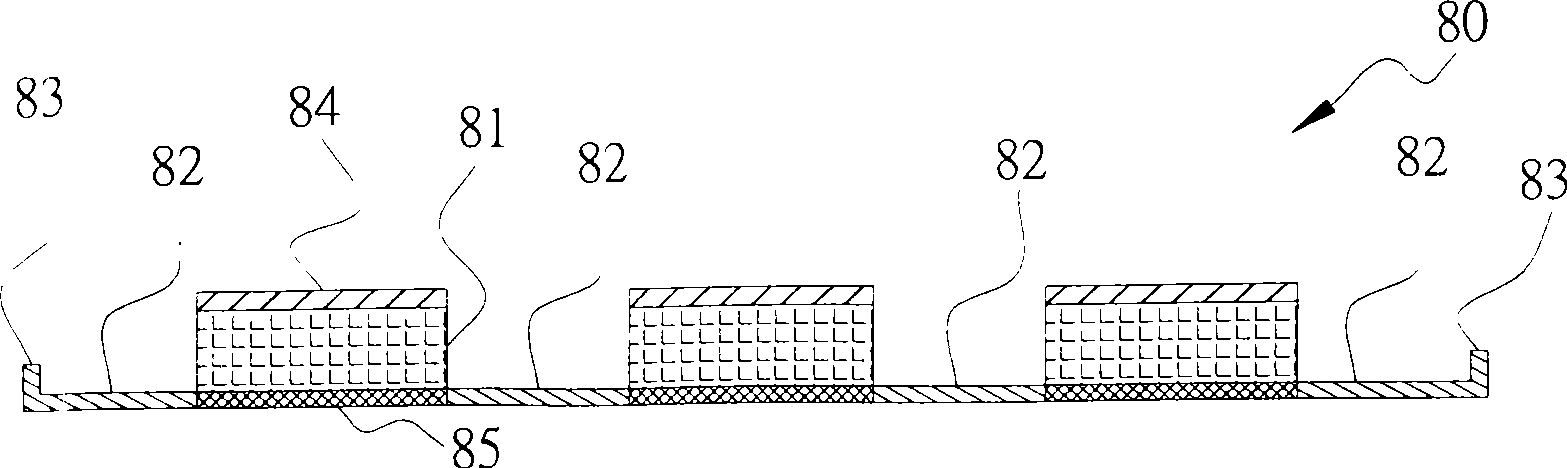

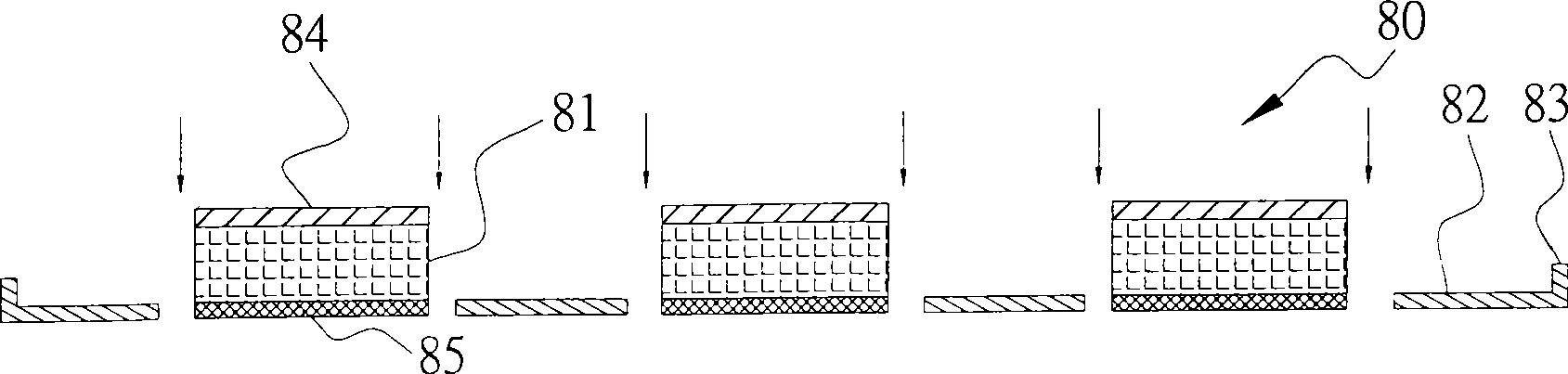

[0039] Please read Figure 4 The structure of the button device 1 of the present invention includes a button group 10, a film 20, a printing layer 30 and a positioning sheet layer 40; the button group 10 includes a plurality of button sheets 11, and the plurality of button sheets 11 can be integrated with a transparent resin Forming, the bottoms of the adjacent button sheets 11 are connected with a connecting sheet 12, and the bottom of the button sheet 11 at the end is extended with a side sheet 13; the film 20 (Film) is a transparent layer (or see-through layer), used to support and connect the button group 10, that is, the plurality of button sheets 11 are consolidated on the top surface of the film 20; the printing layer 30 is located on the bottom surface of the film 20, and can be printed Printed on the film 20 to form fonts, symbols, etc. relative to the button sheet 11; the positioning sheet 40 is located under the film 20 and the printing layer 30, and the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com