Soft switch welding inverter, phase-shifting control method and soft switching method

An inverter power supply, phase-shift control technology, applied in welding equipment, irreversible DC power input conversion to AC power output, electrical components, etc. The effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

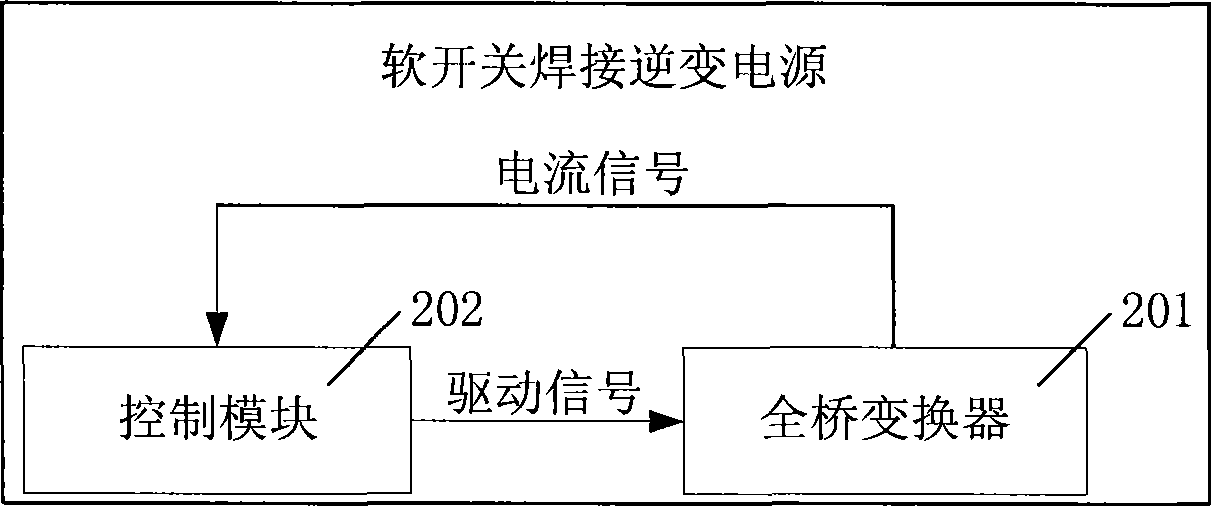

[0055] This embodiment provides a soft switching welding inverter power supply, such as figure 2 As shown, it includes a full bridge converter 201 and a control module 202 .

[0056] A full-bridge converter 201, configured to work according to the driving signal generated by the control module 202;

[0057] The control module 202 is used to receive the current signal of the full-bridge converter 201, and adjust the dead time of the phase-shift signal according to the current signal. The adjusted phase-shift signal is a control signal, and the control signal is isolated and amplified to form a drive signal Drive the full bridge converter 201 to work.

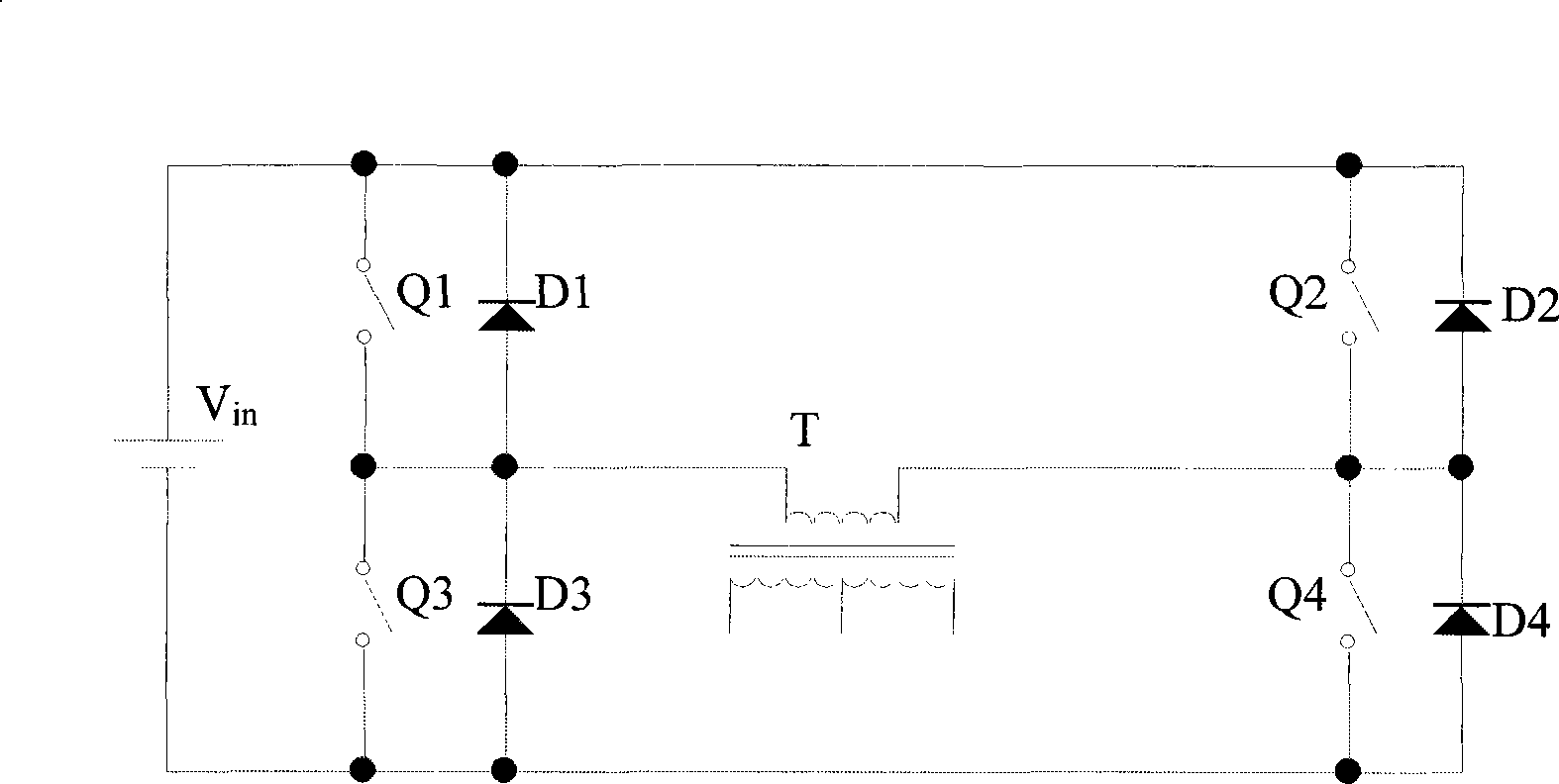

[0058] The circuit topology of the full bridge converter 201 is as follows image 3 Shown:

[0059] The first absorbing capacitor C1 and the third absorbing capacitor C3, C1 is connected in parallel to the first switching device Q1 of the super forearm, and C3 is connected in parallel to the third switching device Q3 of the s...

Embodiment 2

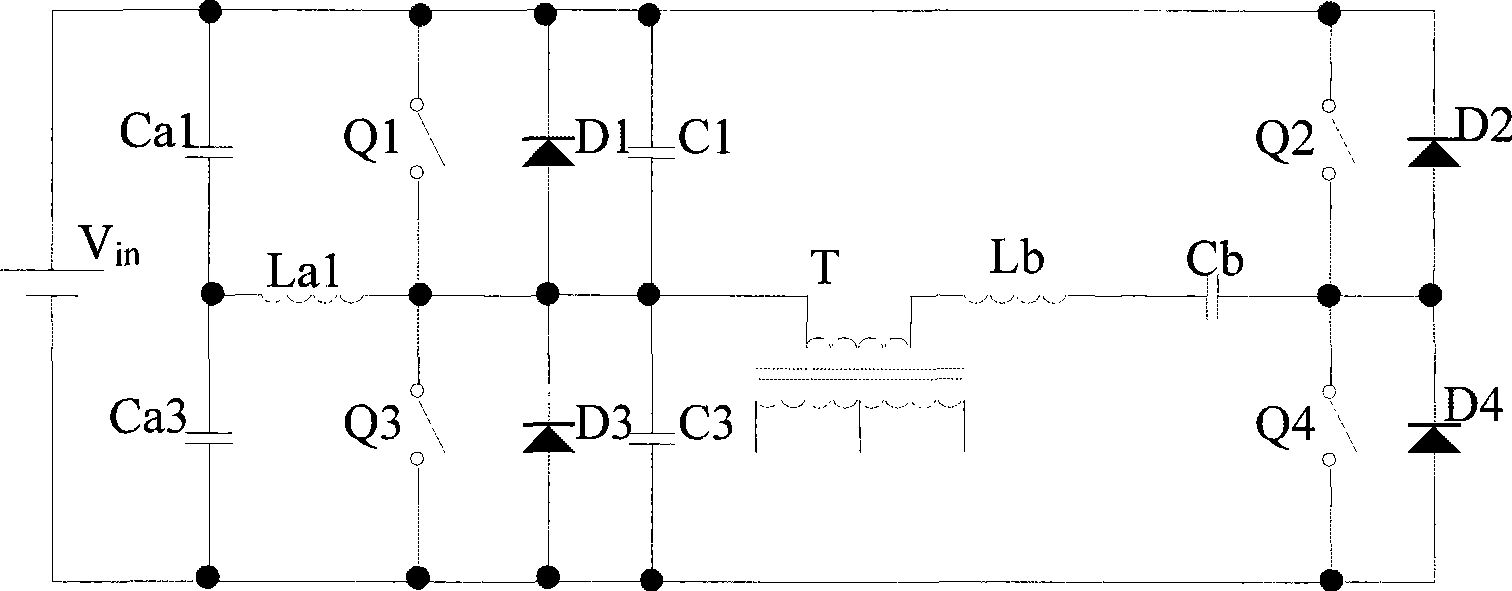

[0073] This embodiment provides a soft switching welding inverter power supply, such as figure 2 As shown, it includes a full bridge converter 201 and a control module 202 . The circuit topology of the full bridge converter 201 is as follows Figure 7 Shown:

[0074] The first absorbing capacitor C1 and the third absorbing capacitor C3, C1 is connected in parallel to the first switching device Q1 of the super forearm, and C3 is connected in parallel to the third switching device Q3 of the super forearm, and C1 and C3 are used to jointly realize full switching of Q1 and Q3 Approximate zero-voltage shutdown of the load range;

[0075] The super-forearm auxiliary resonant network includes two series-connected auxiliary resonant capacitors Ca1 and Ca3 connected in parallel on the super-forearm, an auxiliary resonant inductor La1 connected to the midpoint of the super-forearm Q1 and Q3 and two series-connected auxiliary resonant capacitors Ca1 and Ca3 The middle point is used t...

Embodiment 3

[0082] This embodiment provides a phase-shift control method, which is applied to the soft-switching welding inverter power described in Embodiment 1 and Embodiment 2. Here, the soft-switching welding inverter power supply in Embodiment 1 is taken as an example.

[0083] In the full-bridge converter with phase-shift control, the realization of soft switching requires that the dead time of switching devices of the leading arm and the lagging arm be coordinated with the energy in the circuit, and the phase-shift control method of adaptive adjustment of the dead time is It means that the switching dead time of the power switching device of the advanced forearm and the lagging arm decreases with the increase of the transformer current (such as the primary current of the transformer or the output current of the power supply), and the dead time of the advanced forearm has a large adjustment range, while The adjustment range of the dead time of the lagging arm is small, and the laggi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com