Longitudinal towing mechanism and steering frame with the longitudinal towing mechanism

A technology for a traction device and a bogie, which is applied to the traction device, the bogie, the device for lateral relative movement between the underframe and the bogie, etc., can solve the problems of increased lateral stiffness of the bogie, wear of the traction rod, and large lateral stiffness. , to reduce maintenance frequency, avoid stress concentration, and ensure the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0042] It should be noted that: In this part, while describing the bogie, the longitudinal traction device will be described, and the longitudinal traction device will not be described separately.

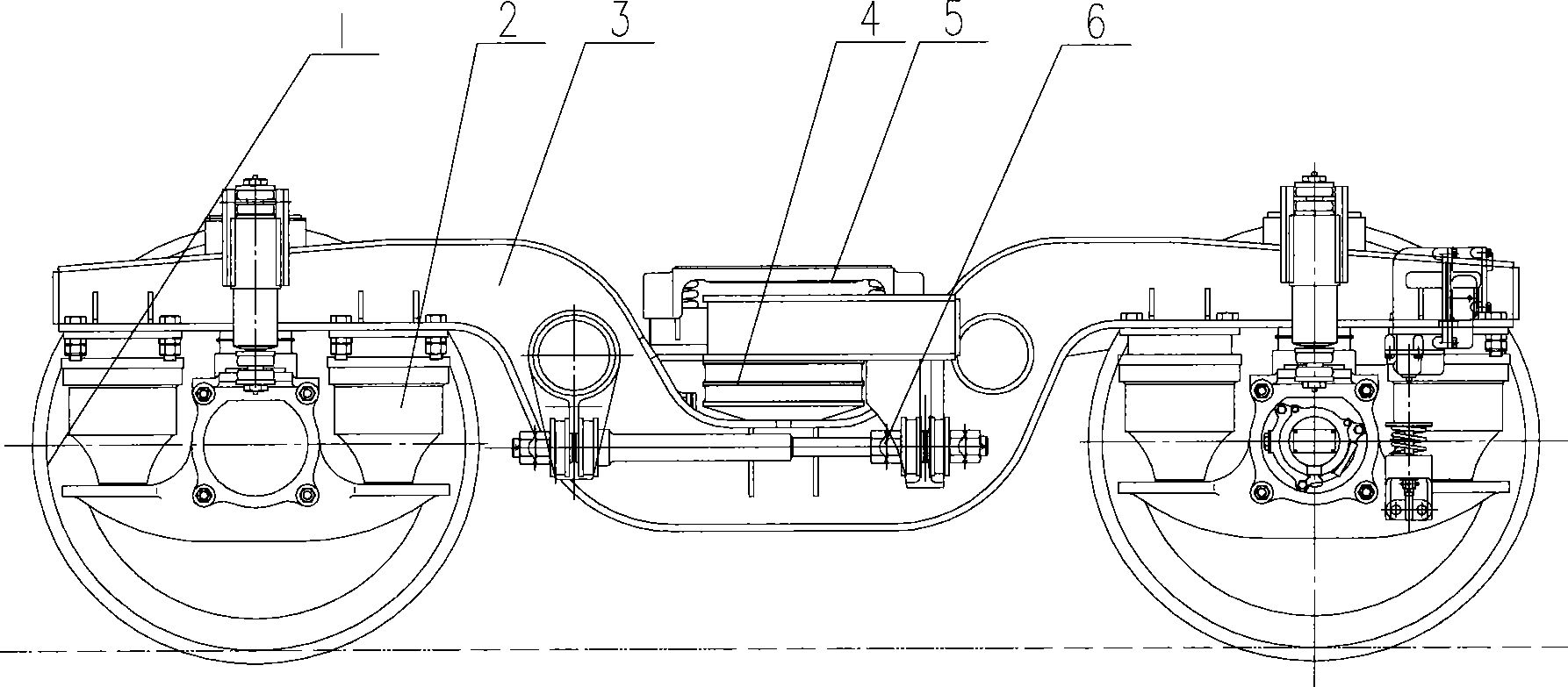

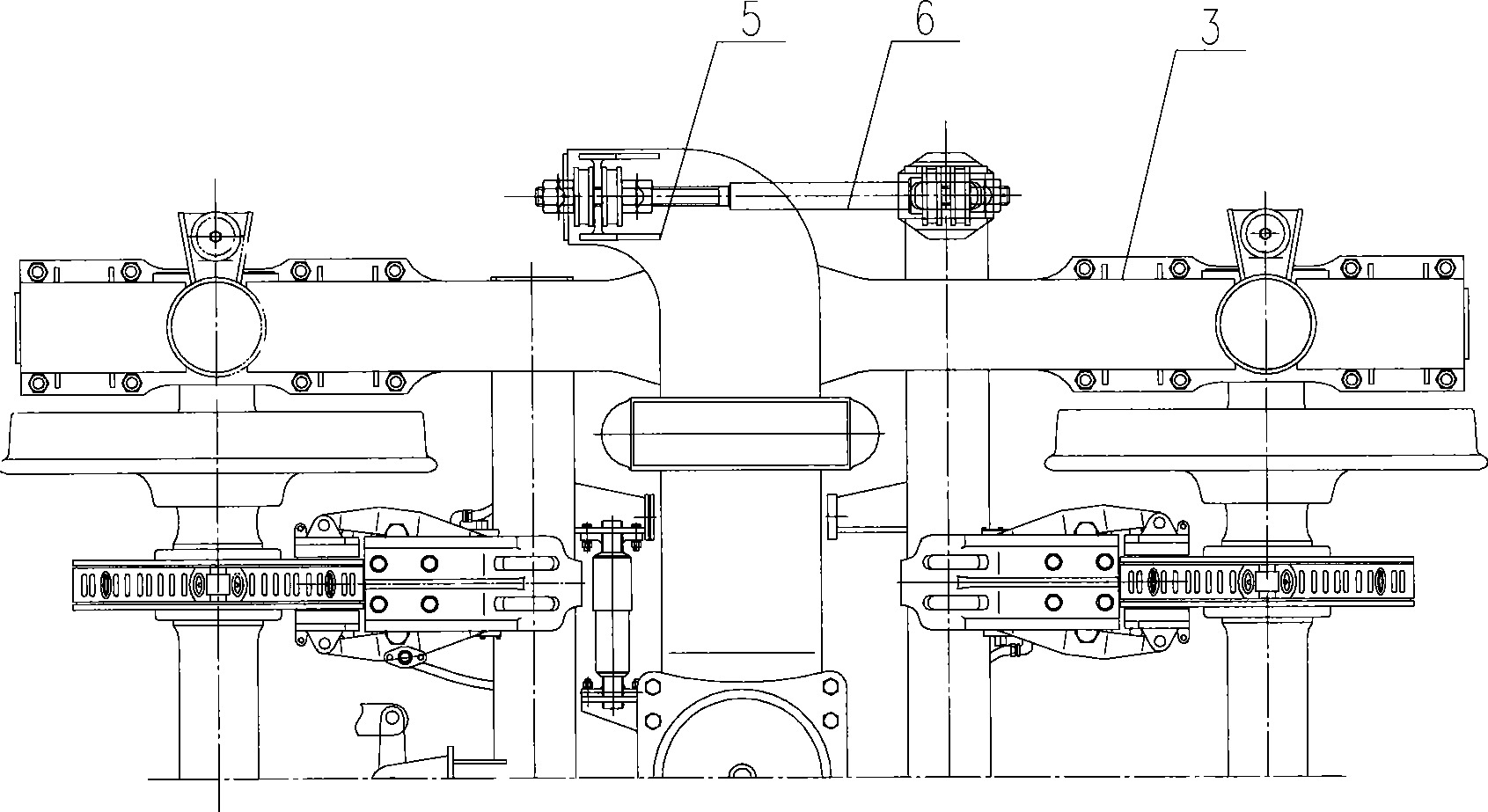

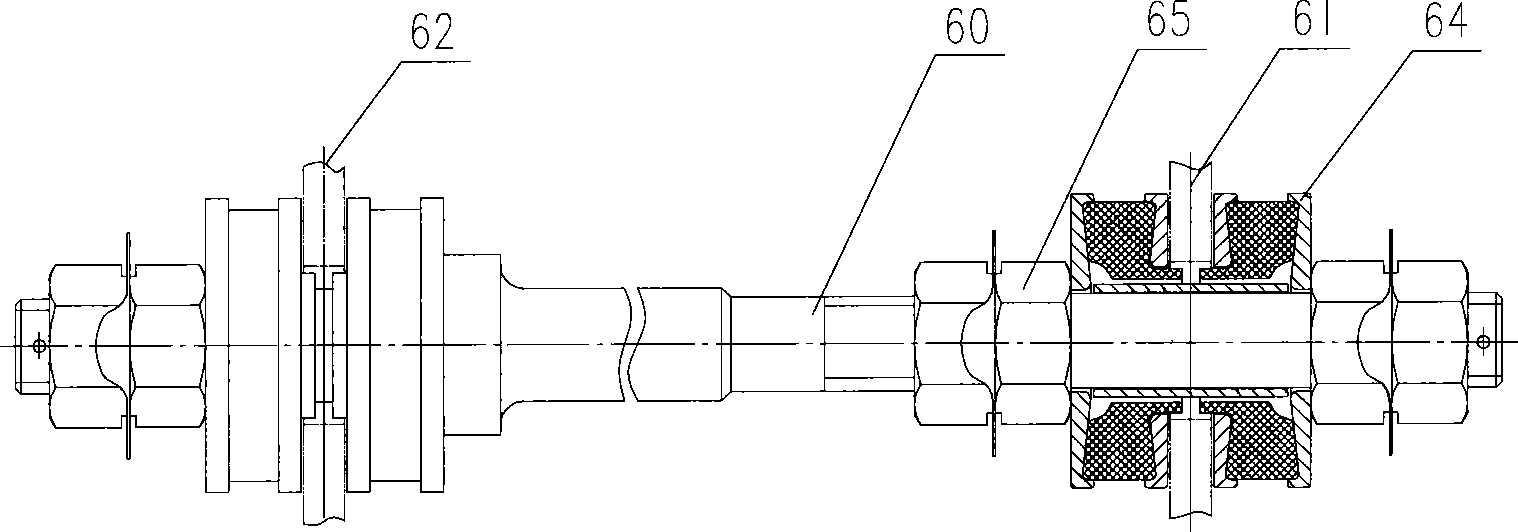

[0043] Such as Figure 4 with Figure 5 As shown, the bogie provided by the embodiment includes a wheel set 1 , a primary suspension system 2 , a frame 3 , a secondary central suspension system 4 , and a bolster 5 . The connection relationship of its various parts is the same as that of the prior art. The bolster 5 has a lower center plate matched with the truck box, and is installed in the middle of the frame 3 through the secondary central suspension system 4, and the frame 3 is installed in the middle of the frame 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com