Super-hydrophobic adhesive film

A super-hydrophobic and super-hydrophobic surface technology, applied in the direction of adhesives, film/sheet adhesives, chemical instruments and methods, etc., can solve the problem of inability to realize large-scale application of super-hydrophobic surfaces, low mechanical strength of super-hydrophobic surfaces, Can not meet the actual needs and other problems, to achieve the effect of easy promotion, soft nature and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

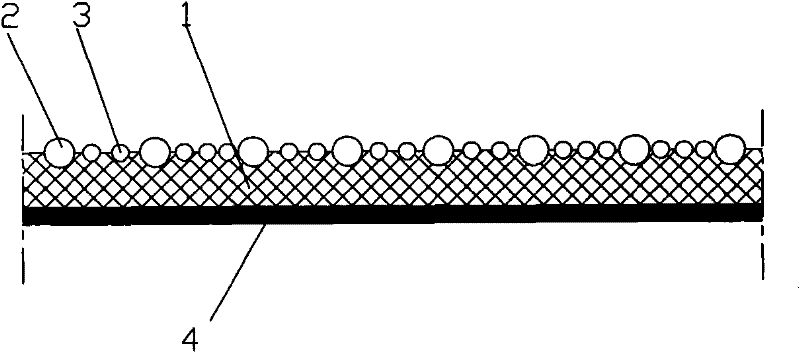

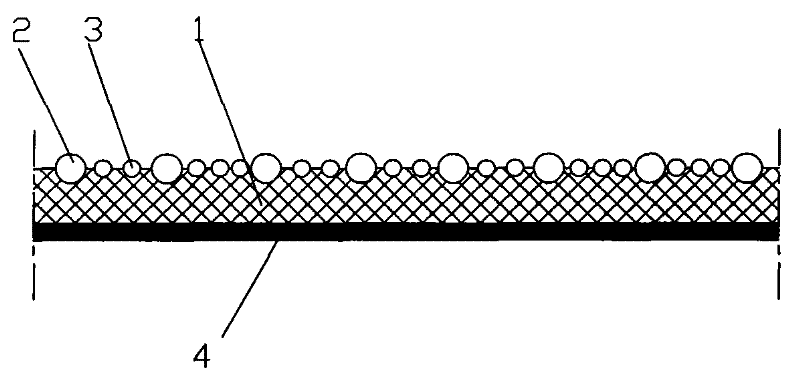

[0021] The superhydrophobic adhesive film of this embodiment includes a superhydrophobic film provided with a superhydrophobic surface, and a non-superhydrophobic surface of the superhydrophobic film is provided with an adhesive adhesive layer 4. In this embodiment, the adhesive adhesive layer 4 is a pressure-sensitive adhesive layer. Easy to use and good adhesion; the super-hydrophobic membrane includes a membrane base 1 and a super-hydrophobic layer arranged on the surface of the membrane base 1. The material of the membrane base 1 is polyimide, which has soft physical properties, high strength and strong adaptability , thermoplastic, can be prepared by hot pressing, applicable to various surfaces, suitable for setting adhesive layer, low production cost; super-hydrophobic layer is composed of micron-sized powder particles 2 and nano-sized powder particles that are arranged alternately and embedded in the film matrix 3. The micron-sized powder 2 and the nano-sized powder 3 fo...

Embodiment 2

[0025] The superhydrophobic adhesive film of this embodiment includes a superhydrophobic film provided with a superhydrophobic surface, and a non-superhydrophobic surface of the superhydrophobic film is provided with an adhesive adhesive layer 4. In this embodiment, the adhesive adhesive layer 4 is a pressure-sensitive adhesive layer. Easy to use and good adhesion; the super-hydrophobic membrane includes a membrane base 1 and a super-hydrophobic layer arranged on the surface of the membrane base 1. The material of the membrane base 1 is polyester resin, which has soft physical properties, high strength, strong adaptability, and Thermoplastic, can be prepared by hot pressing method, applicable to various surfaces, suitable for setting adhesive layer, low production cost; super-hydrophobic layer is composed of micron-sized powder particles 2 and nano-sized powder particles 3 arranged alternately and embedded in the membrane matrix , the micron-sized powder 2 and the nano-sized po...

Embodiment 3

[0029] The superhydrophobic adhesive film of this embodiment includes a superhydrophobic film provided with a superhydrophobic surface, and a non-superhydrophobic surface of the superhydrophobic film is provided with an adhesive adhesive layer 4. In this embodiment, the adhesive adhesive layer 4 is a pressure-sensitive adhesive layer. Easy to use and good adhesion; the super-hydrophobic membrane includes a membrane base 1 and a super-hydrophobic layer arranged on the surface of the membrane base 1, the super-hydrophobic membrane includes a membrane base 1 and a super-hydrophobic layer arranged on the surface of the membrane base 1, the membrane base 1 The material is acetate cloth, which has soft physical properties, high tensile strength and strong adaptability. It can be applied to various surfaces and is suitable for setting adhesive layers. The material cost is low and the production cost is low; the superhydrophobic layer is arranged and embedded The film matrix is compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com