Laser impact intensified on-line detection method and apparatus based on waveform characteristics of shock wave

A technology of laser shock strengthening and waveform characteristics, which is applied in the direction of measuring devices, ultrasonic/sonic/infrasonic generation, instruments, etc., to achieve the effect of strong practicability, small external influence, and accurate judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

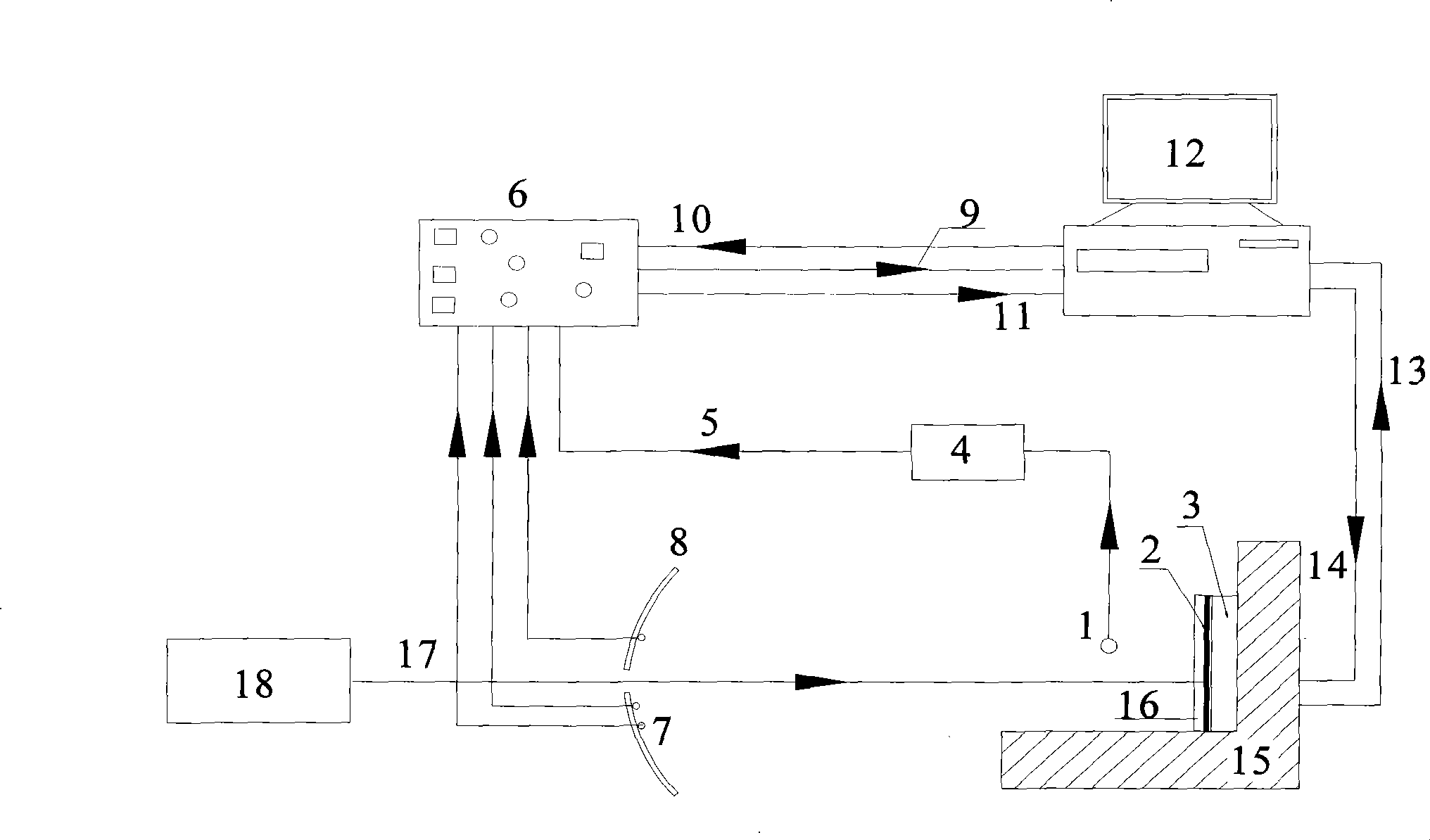

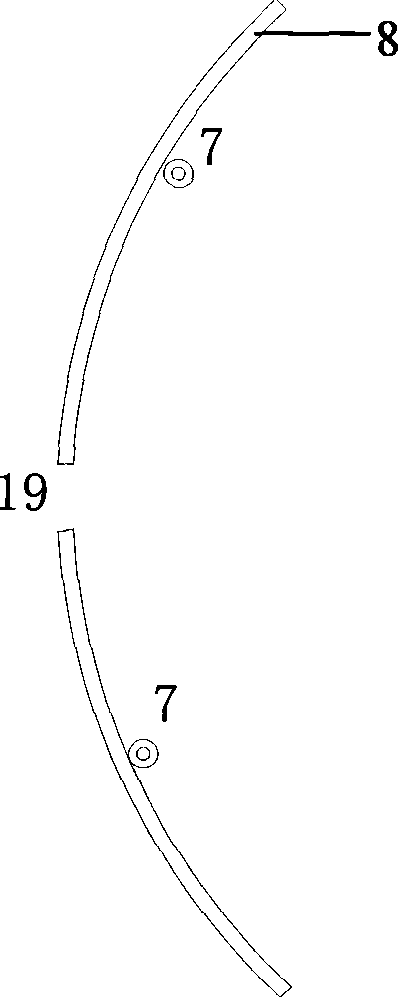

[0019] Combine below figure 1 , figure 2 The details and operation of the method and apparatus of the present invention are described in detail. The device for realizing the real-time detection method includes a laser generator 18, a photoelectric trigger circuit 4, a shock wave sampling circuit 6, an acoustic sensor device 7, an acoustic wave absorbing component 8, a control system 12, a five-axis workbench 15 and other auxiliary parts. In the online detection process of laser shock strengthening, the working steps to realize the method, as well as the specific functions and parameters of each part of the detection device are as follows:

[0020] (1) The photoelectric trigger circuit 4 is composed of the photosensitive element 1, its peripheral circuits and a trigger circuit. The laser 18 emits a short-pulse high-power laser beam 17, passes through the water confinement layer 16, and irradiates on the aluminum foil absorbing layer 2 to generate plasma luminescence. The ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com