Control method of hair straightener

A control method and hair straightener technology, which are applied in temperature control, non-electric variable control, control/regulation system, etc., can solve problems such as increasing cost, and achieve the effects of convenient debugging, fast calculation speed and simple circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

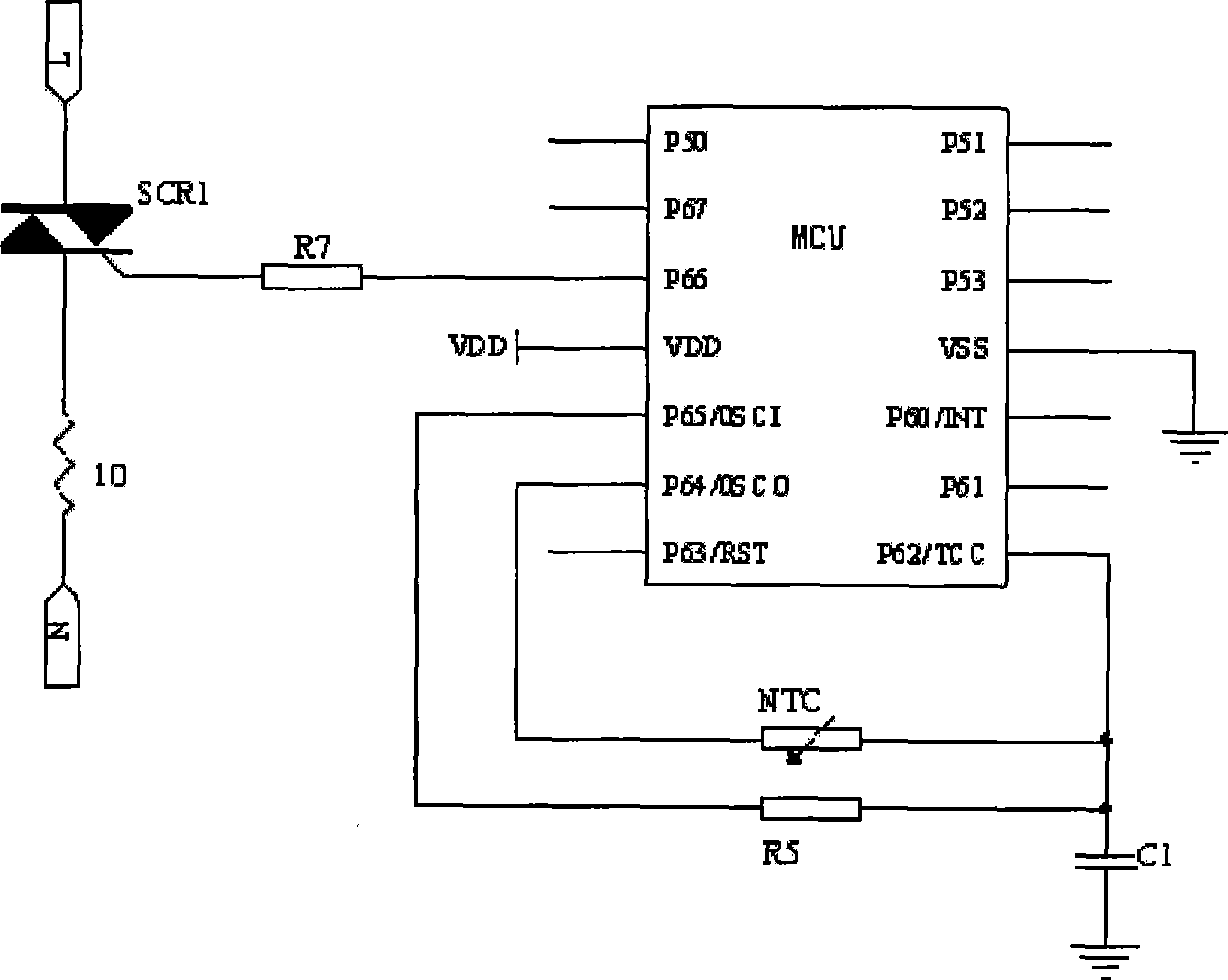

[0011] figure 1 A circuit for implementing the method of the invention is shown.

[0012] Such as figure 1 As shown, the circuit includes a multi-point control unit MCU, a capacitor C 1 , standard resistance R 5 and negative coefficient thermistor NTC. The MCU adopts Elan's 78P153, the MCU does not have an AD converter, and the price is very low; the resistance value of the standard resistor R5 is R; the capacitor C 1 One end is grounded, and the other end is connected to the P62 port of the MCU; one end of the negative coefficient thermistor NTC is connected to the P64 port of the MCU, and the other end is connected to the P62 port of the MCU and the capacitor C 1 between; standard resistance R 5 One end is connected to the P65 port of the MCU, the other end is connected to the P62 port of the MCU and the capacitor C 1 Between; the thyristor SCR1 is connected in series with the heating element 10, and the thyristor SCR1 passes through the resistance R 7 Connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com