Stator winding construction and winding method for slotless motor stator winding, and stator construction with the winding construction

A slotless motor and stator winding technology, which is applied in the shape/style/structure of winding conductors, electric components, and the manufacture of motor generators, etc. problem, to avoid circulating current, increase copper loss, and reduce eddy current loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further description will be made below in conjunction with the description of the drawings and specific implementation methods.

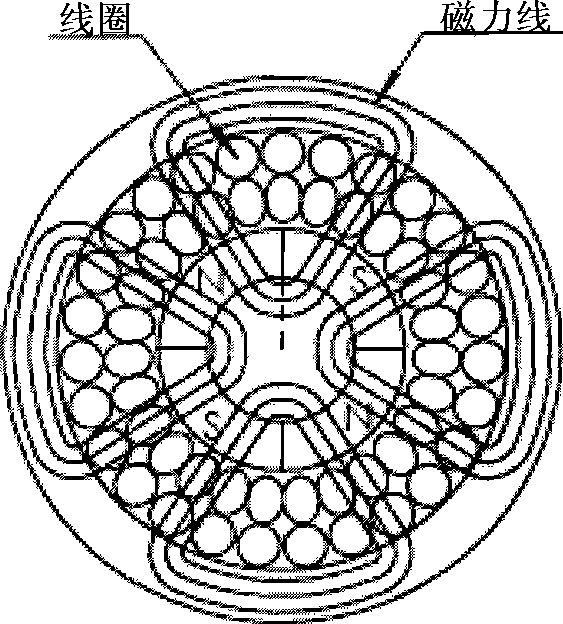

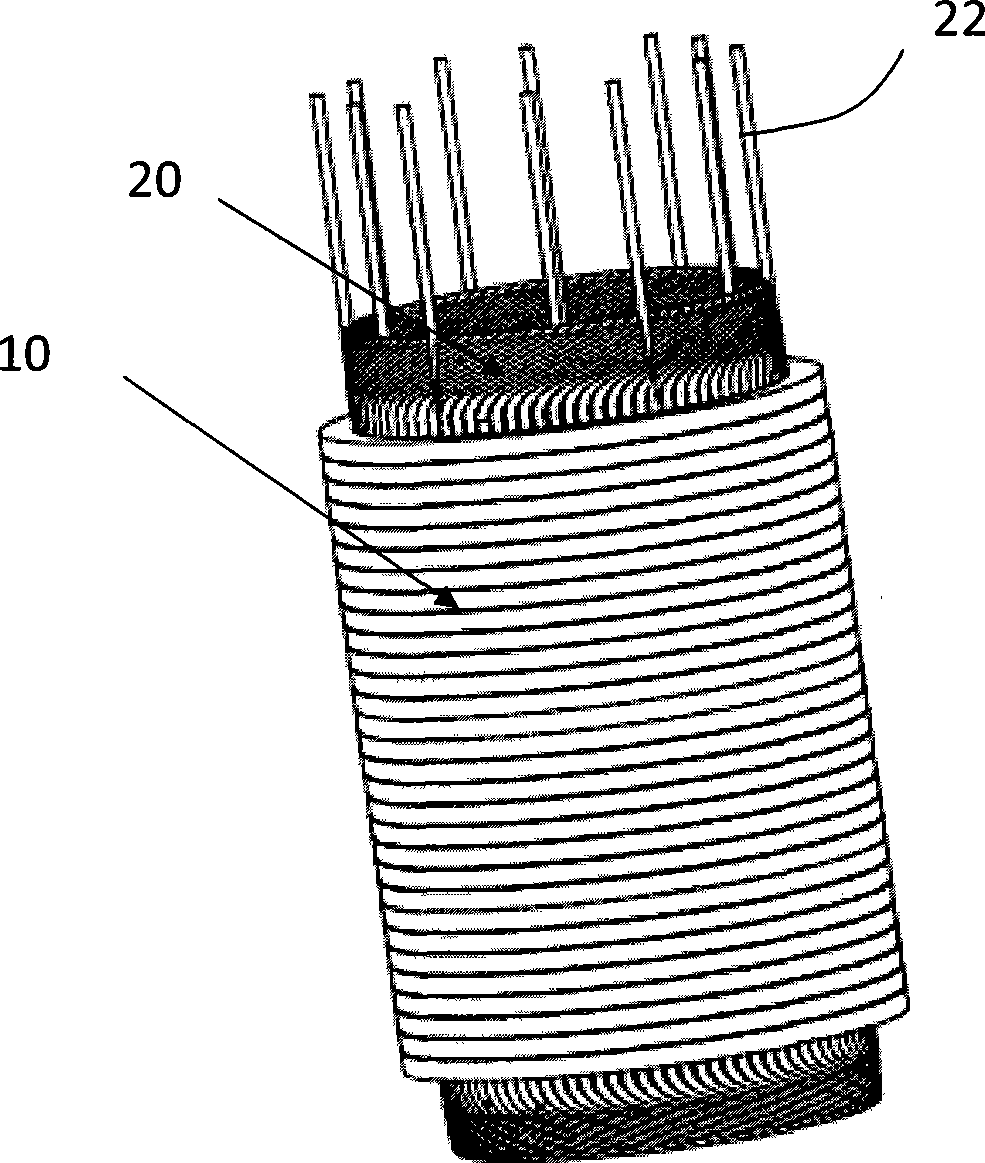

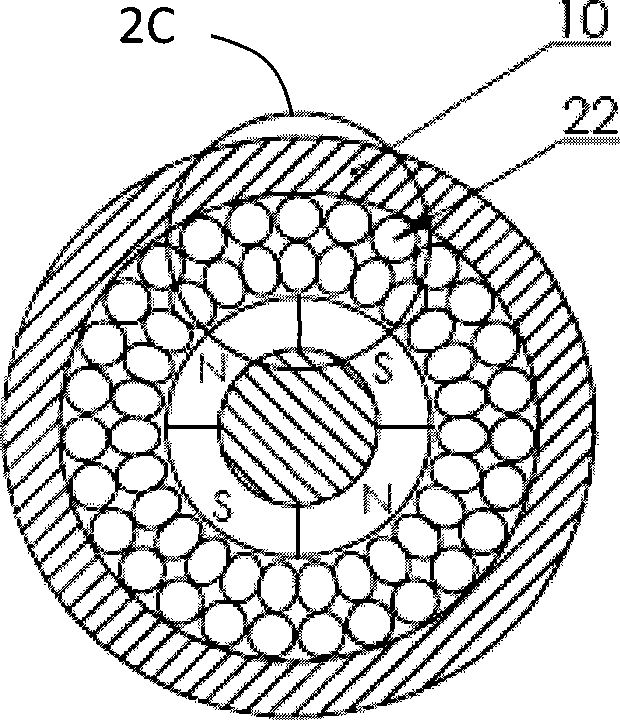

[0024] Figure 2a to Figure 2c Shown is a stator structure of a slotless motor according to an embodiment of the present invention, which includes a cylindrical stator core 10 and a stator winding 20 fixed in the core. The winding 20 is wound by a multi-strand wire group 22, each wire group 22 is twisted into a helical shape by a plurality of insulated wires 22a, and the ends of the plurality of insulated wires 22a are respectively welded together, so that the plurality of insulated wires 22a are welded together. The insulated wires 22a are connected in parallel to form a wire group 22. The multi-strand wire groups 22 are electrically connected to each other in a Y shape or a Δ shape. In this embodiment, the winding 20 is wound by six wire groups 22, and each wire group 22 is twisted into a helical shape by six insulated wires 22a.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com