Machine for coiling large bundle of wire

A large-coil and reel technology, which is applied in the field of key equipment large-coil coilers, can solve problems such as connection structure, unreasonable process design, complex structure of the gearbox, and many parts of the gearbox, so as to achieve convenient daily maintenance and reduce equipment weight , the effect of reducing maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

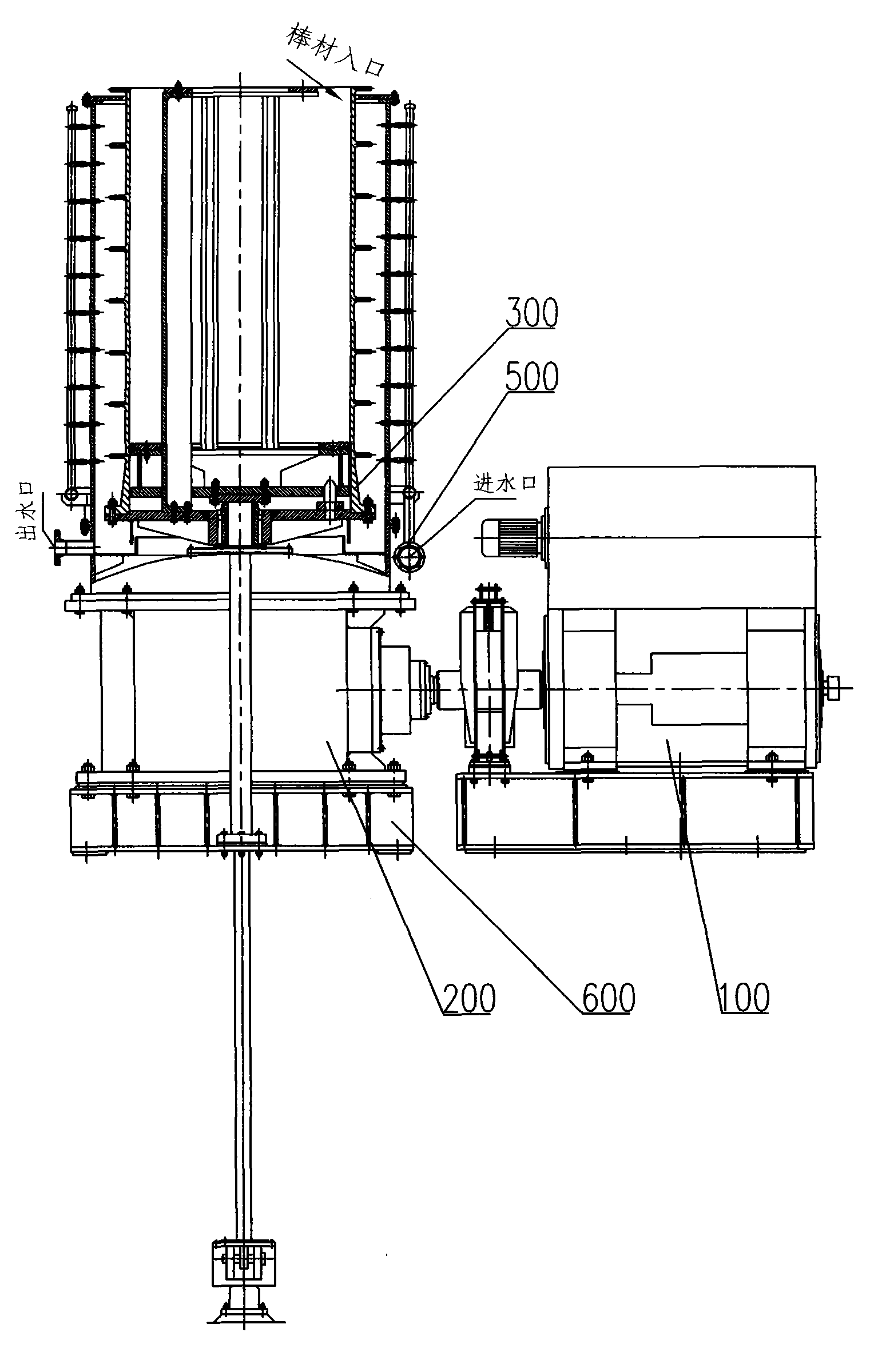

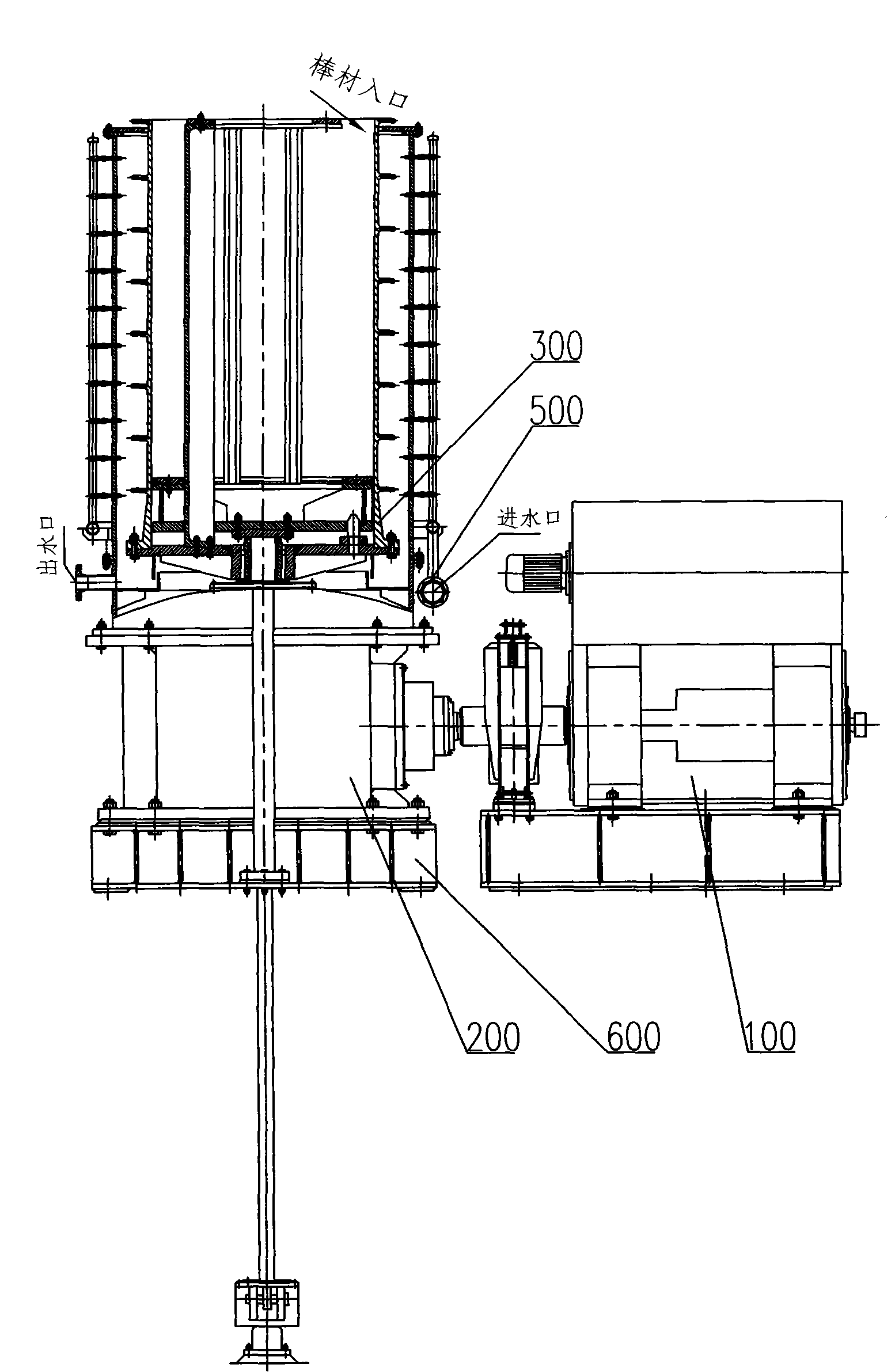

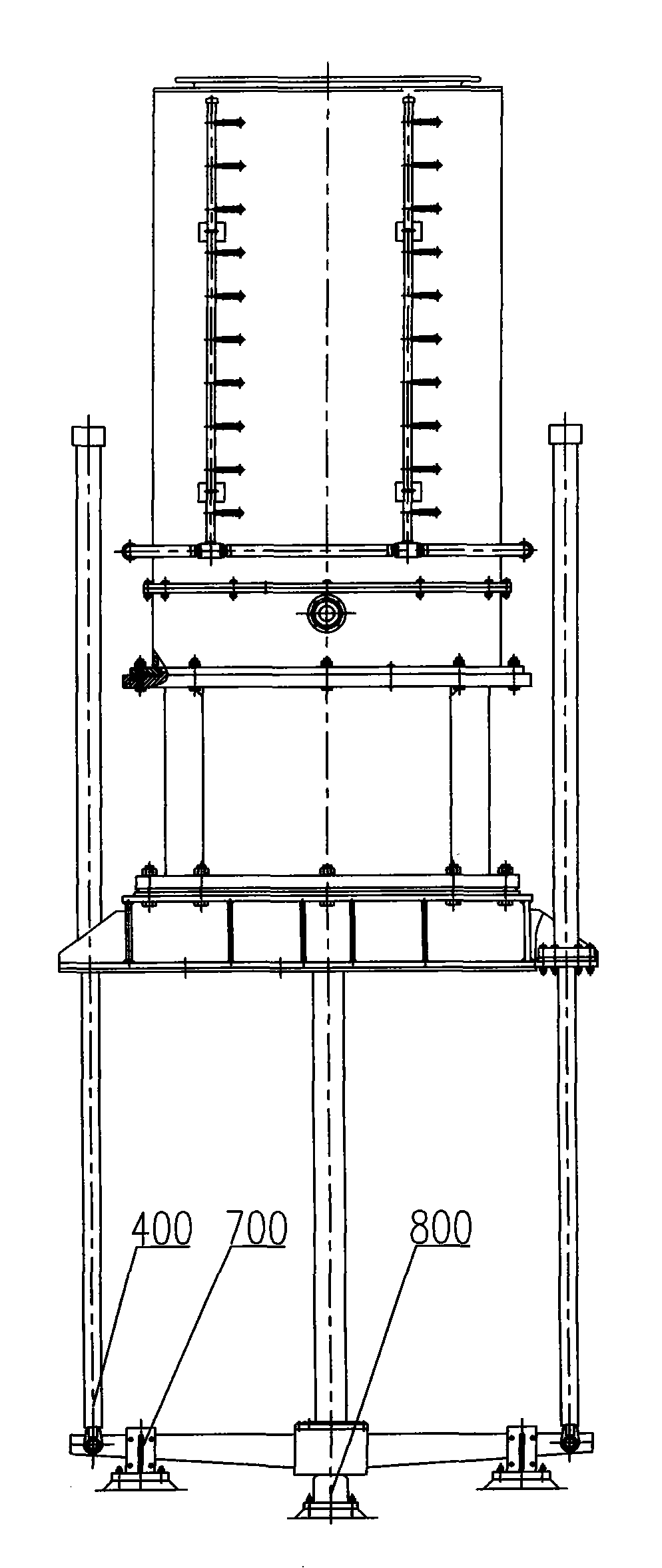

[0029]A large coil coiler (refer to FIG. 1 ) includes a motor device 100, a reduction box 200, a reel device 300, a coiling device 400, a cooling device 500, and a base 600, wherein the reduction box 200 is arranged on the base 600, and the coil The drum device 300 is arranged on the reduction box 200 , the cooling device 500 is arranged on the outer circumference of the drum device 300 , the motor device 100 is connected with the reduction box 200 and provides power for the whole system, (refer to FIG. 4 and FIG. 5 ) the reduction box 200 It includes a box body 201 , a box cover 202 and a pair of gears 204 , one of which is arranged on the input shaft 213 and the other gear is arranged on the hollow shaft 205 , and the pair of gears is used to convert the horizontal rotational motion of the input shaft 213 The hollow shaft 205 rotates in the vertical direction, the hollow shaft 205 and the box body 201 are supported by two bearings 208, and an upper end cover 206 and a lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com