Multifunctional cement adjustable solidification agent and preparation thereof

A coagulant and multi-functional technology, applied in the field of multi-functional cement coagulant and its preparation, can solve the problems of complex implementation process and achieve the effects of simple process, lower production cost and higher utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) With the sulfuric acid waste liquid containing aminonaphthalenesulfonic acid produced in the preparation process of the naphthalene series dye intermediate as raw material, the waste liquid is neutralized to a pH value of 10 with lime, and then the water content of press filtration to the filter residue is 9.5 %;

[0025] (2) Concentrate the filtrate to a water content of 41%, then add the concentrated filtrate accounting for 4.3% of the total weight of the filter residue and the concentrated filtrate to the filter residue, extrude into a ball machine, granulate and steam dry at 85°C to make a multifunctional cement Coagulant.

[0026] After testing, the CaSO in the multifunctional cement set modifier 4 2H 2 O content in SO 3 The percentage by weight of the compound is 37.2%, the percentage by weight of attached water is 5.5%, and the percentage by weight of calcium aminonaphthalenesulfonate is 2.4%.

Embodiment 2

[0028] (1) With the sulfuric acid waste liquid containing aminonaphthalenesulfonic acid produced in the preparation process of the naphthalene series dye intermediate as raw material, the waste liquid is neutralized to a pH value of 10 with lime, and then the water content of press filtration to the filter residue is 11.3 %;

[0029] (2) Concentrate the filtrate to a water content of 41.3%, then add concentrated filtrate accounting for 3.3% of the total weight of the filter residue and concentrated filtrate to the filter residue, extrude into a ball machine, granulate and steam dry, and the drying temperature is about 90°C. Multi-functional cement set modifier.

[0030] After testing, the CaSO in the multifunctional cement set modifier 4 2H 2 O content in SO 3 The percentage by weight of the compound is 38%, the percentage by weight of attached water is 5.1%, and the percentage by weight of calcium aminonaphthalenesulfonate is 2.0%.

Embodiment 3

[0032] (1) With the sulfuric acid waste liquid containing aminonaphthalenesulfonic acid produced in the preparation process of the naphthalene series dye intermediate as raw material, the waste liquid is neutralized to a pH value of 9.0 with lime, and then the water content of press filtration to the filter residue is 13.5 %;

[0033] (2) Concentrate the filtrate to a water content of 49.7%, then add the concentrated filtrate accounting for 2.8% of the total weight of the filter residue and the concentrated filtrate to the filter residue, extrude into a ball machine, granulate and steam dry, and the drying temperature is about 95°C. Multi-functional cement set modifier.

[0034] After testing, the CaSO in the multifunctional cement set modifier 4 2H 2 O content in SO 3 The percentage by weight of the compound is 38.5%, the percentage by weight of attached water is 5.8%, and the percentage by weight of calcium aminonaphthalenesulfonate is 1.6%.

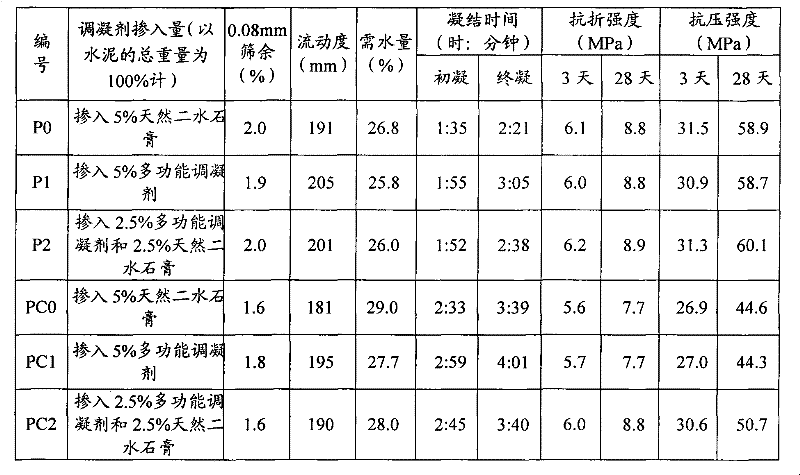

[0035] The multifunctional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com