Earth-steel combined cofferdam construction method for underwater pile cap of bridge

A technology of water bearing platform and construction method, which is applied in the direction of basic structure engineering, construction, caisson, etc., can solve the problems of high difficulty in quality control, long construction period, large investment in temporary structures, etc., and achieves easy quality control, shortened construction period, The effect of less consumption of steel and concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

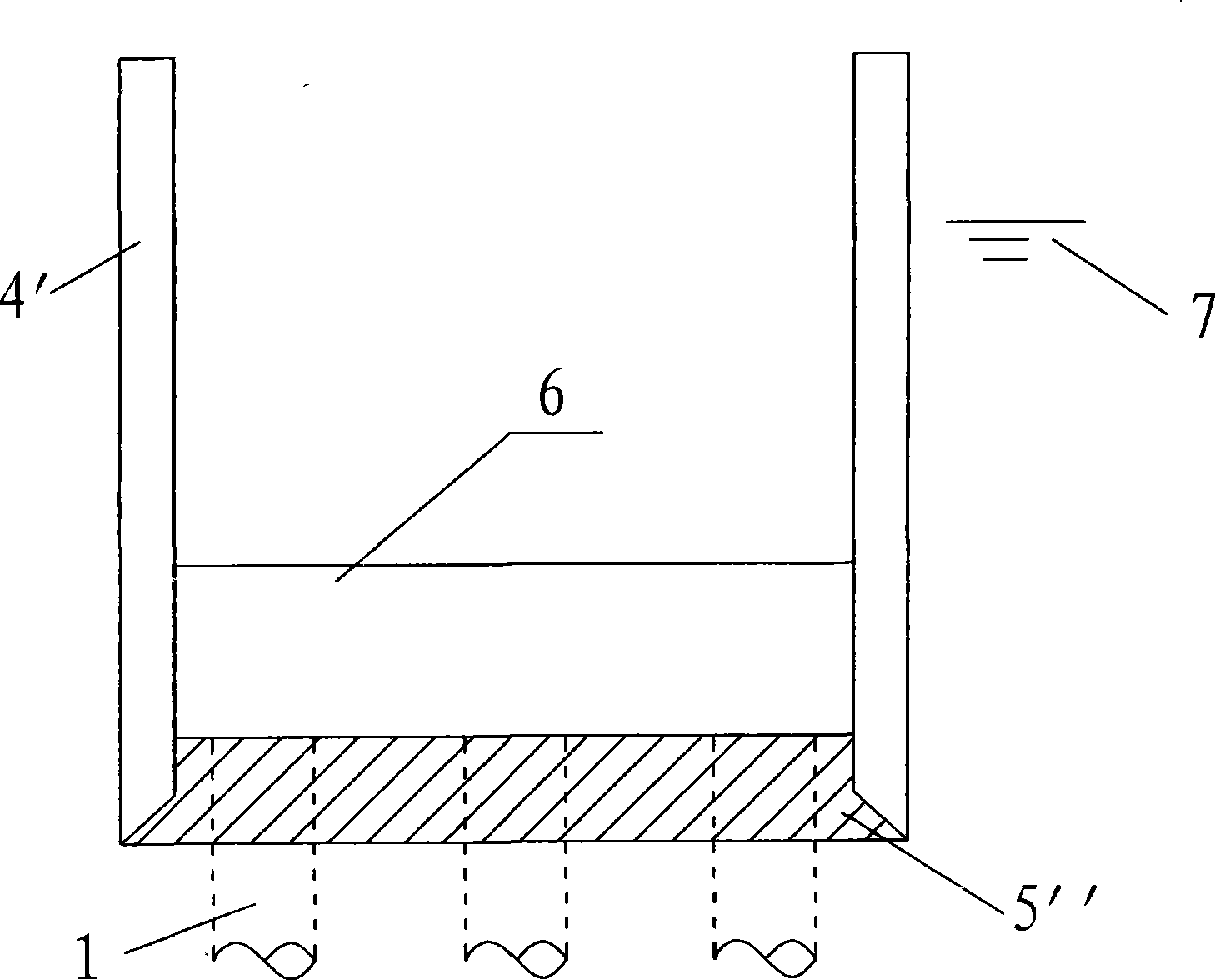

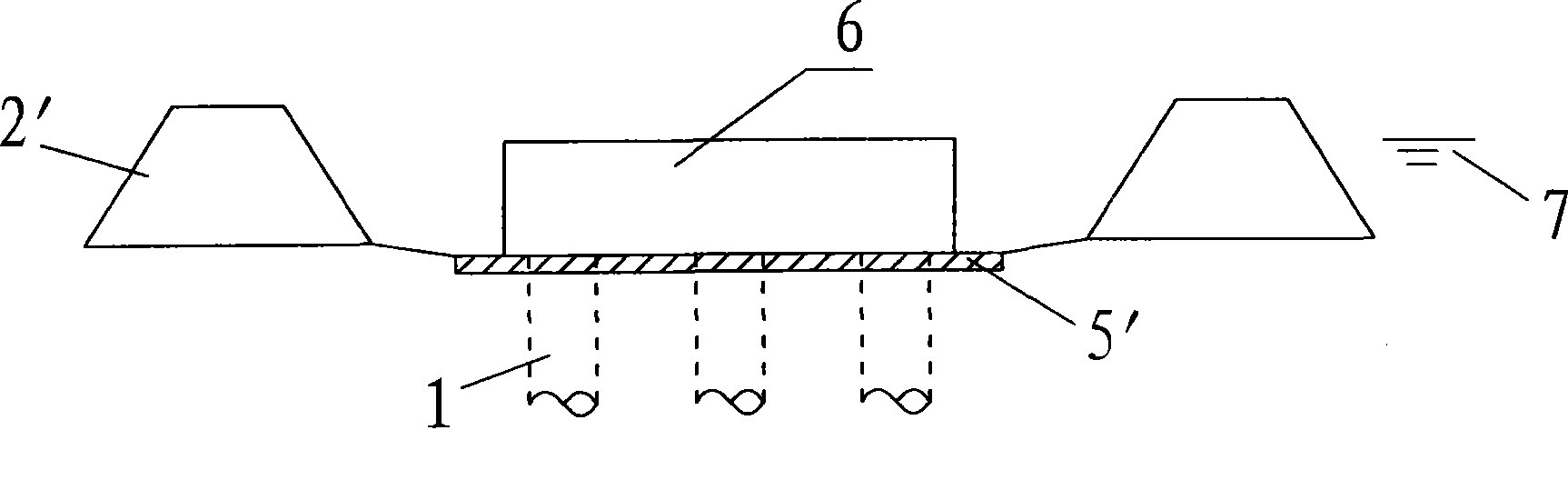

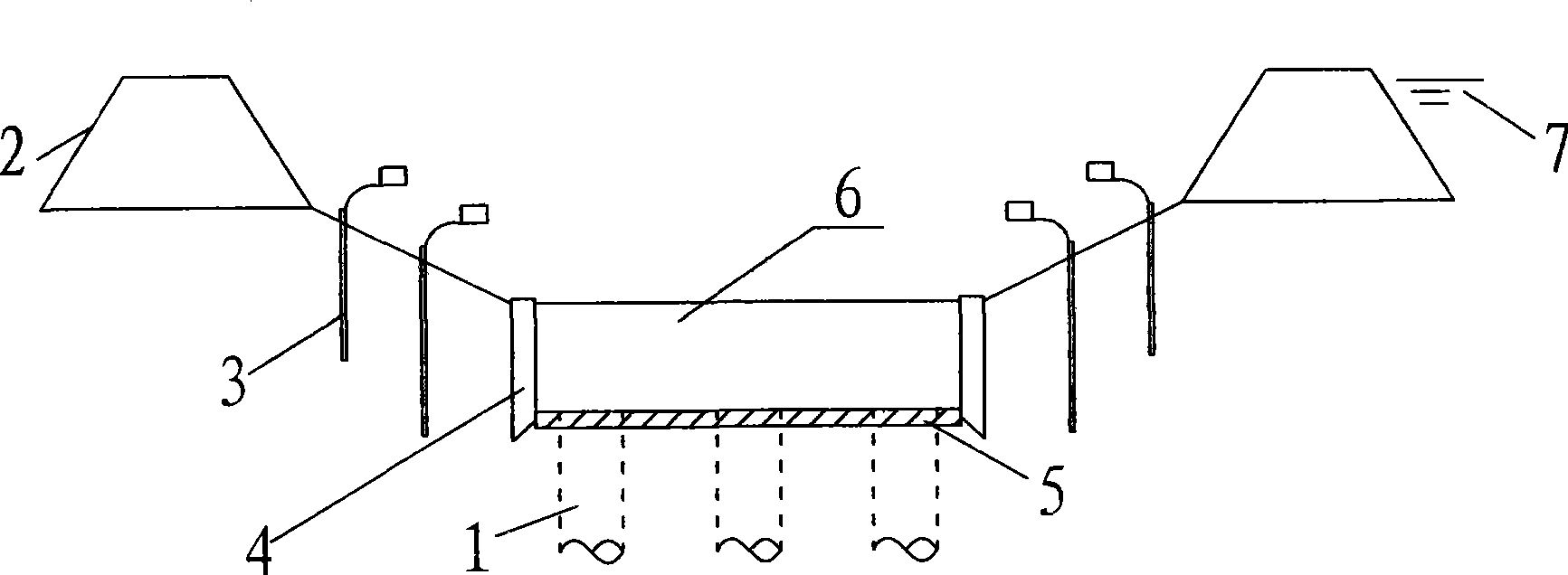

[0023] The size of the main pier cap of a bridge is 25.6×22.5×5.5m, the bottom elevation of the platform is -6.5m, the riverbed elevation is +1.0m, the normal water level elevation is +4.5m, and the tide height is 0.5m. The riverbed soil is a silt layer. Construction of soil-steel cofferdam, see attached image 3 . The specific technical solution is as follows.

[0024] (1) First design the geotechnical cofferdam and steel box according to the construction environment

[0025] ① In order to better resist the external water pressure, the geotechnical cofferdam is designed into an elliptical shape, with a long diameter of 43m and a short diameter of 40m on the centerline of the geotechnical cofferdam. The cross section is designed as a trapezoidal section, with a bottom width of 20m, a top width of 12m, and a height of 4m. It is constructed in 8 layers and formed by sand blowing.

[0026] ②The steel box is a double-wall structure, the inner wall is the same as the shape of the platfo...

Embodiment 2

[0053] The following uses another example to compare the effects of the steel (concrete) box construction method and the soil-steel (concrete) combined cofferdam construction method for the same cap. Table 2 is a table of various parameters of Comparative Example 2.

[0054]

[0055] Table 2: Various parameter tables of Comparative Example 2

[0056] For the above example 2, the steel box method is adopted for construction. The size of the steel box box is 15m in height×96.2m in circumference×1.2m in thickness, and the thickness of the sealed bottom concrete is 2m; The box size is 4m high x 96.2m perimeter x 1.2m thick, the base cushion concrete thickness is 0.7m, the perimeter of the soil cofferdam is 160m, and the height is 5m. Table 3 compares the effects from the aspects of construction period, raw material saving, quality control, and construction investment.

[0057]

[0058] Table 3: Comparison of effects of soil-steel cofferdam method and steel box method for purchase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com