Earth-steel combined cofferdam construction method for underwater pile cap of bridge

A technology of water bearing platform and construction method, which is applied in the direction of basic structure engineering, architecture, caisson, etc., can solve the problems of large investment in temporary structures, high difficulty in quality control, and long construction period, and achieve long construction period, easy quality control, The effect of shortening the construction period

Active Publication Date: 2011-01-05

ROAD & BRIDGE INT

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

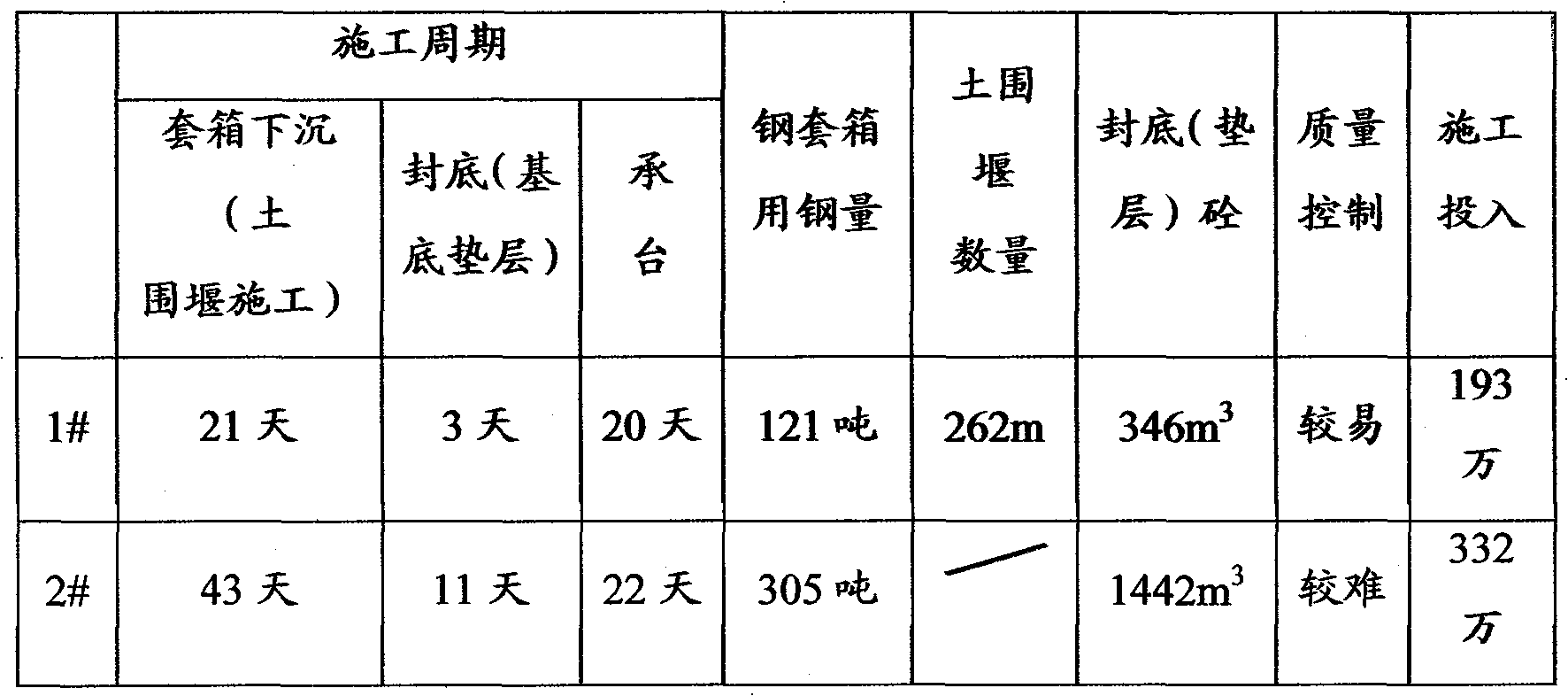

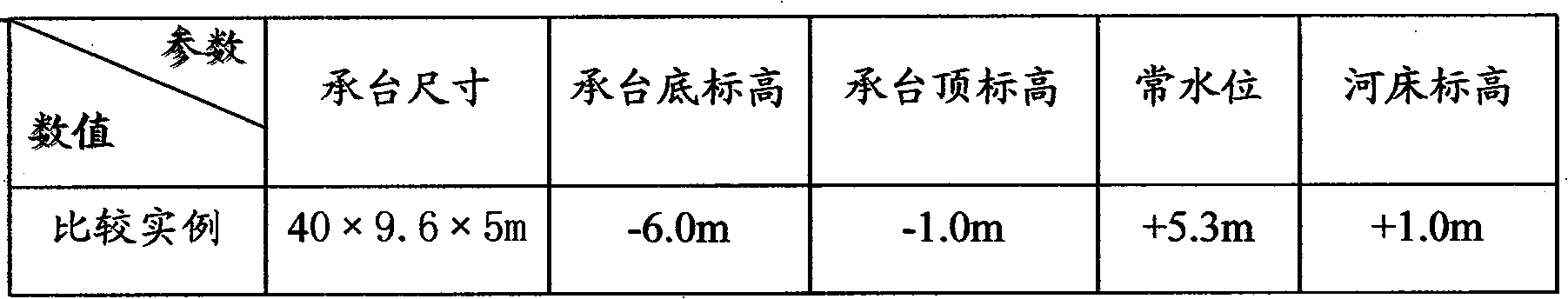

This method can not only expand the scope of application of geotechnical cofferdams, but also solve the problems of long construction period, large investment in temporary structures, and high difficulty in quality control by using only steel (concrete) casings.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A soil-steel combined cofferdam construction method used for a bridge under-water bearing platform includes the following steps: a geotechnical cofferdam is constructed around the bearing platform to be constructed after the pile foundation is completed; a mud pump is adopted to pump the water out from the cofferdam and a well-point dewatering device is arranged and operated inside the cofferdam according to the construction proposal after the geotechnical cofferdam is completed; the completed telescopic caissons are combined at the bridge site and a soil-cleaning device is adopted to taking the soil from the telescopic caissons; the telescopic caissons are sunk and after the telescopic caissons sinks to the designed position the concrete construction for the base cushion is carried out; and the construction for the platform steel reinforcement and concrete is carried out after the intensity of the base cushion concrete meets the requirement.

Description

Construction method of soil-steel combined cofferdam for bridge cap in water technical field The invention relates to a construction method for a bridge bearing platform in water, which belongs to the field of bridge construction. Background technique At present, the construction of bridge caps in water is based on different hydrological conditions, and steel (concrete) casings and geotechnical cofferdams are usually used. A common point of these methods is to isolate the construction area of the caps from the outside water through temporary construction structures, and isolate the construction area. The water inside is drained, and the underwater construction of the platform is transformed into land construction. The main temporary construction structures in the usual steel (concrete) casing construction are steel (concrete) casing and back-sealing concrete, see accompanying drawing 1. Its principle is to utilize the steel (concrete) casing 4' and the back cover concr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E02D19/04E02D23/00

Inventor 李德钦唐世连鲜正洪杨卫平肖向荣

Owner ROAD & BRIDGE INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com