One-time excavation construction method for large-diameter large-depth pressure regulating well pilot shaft

A construction method and large-depth technology, applied in drilling equipment and methods, drilling equipment, earthwork drilling and mining, etc., can solve problems such as hidden safety hazards, high construction costs, and long construction time, so as to speed up the construction schedule and ensure construction safety , The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

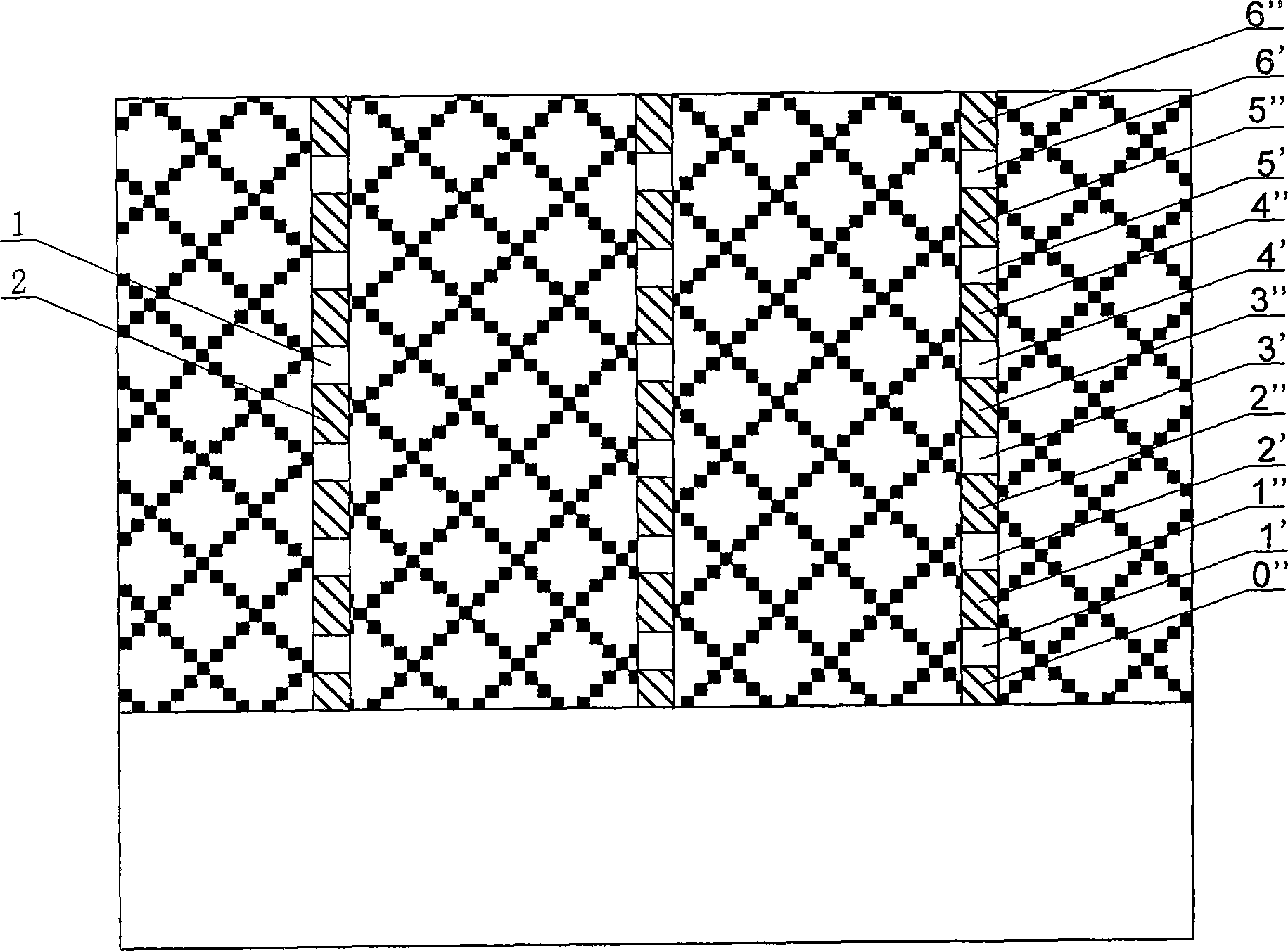

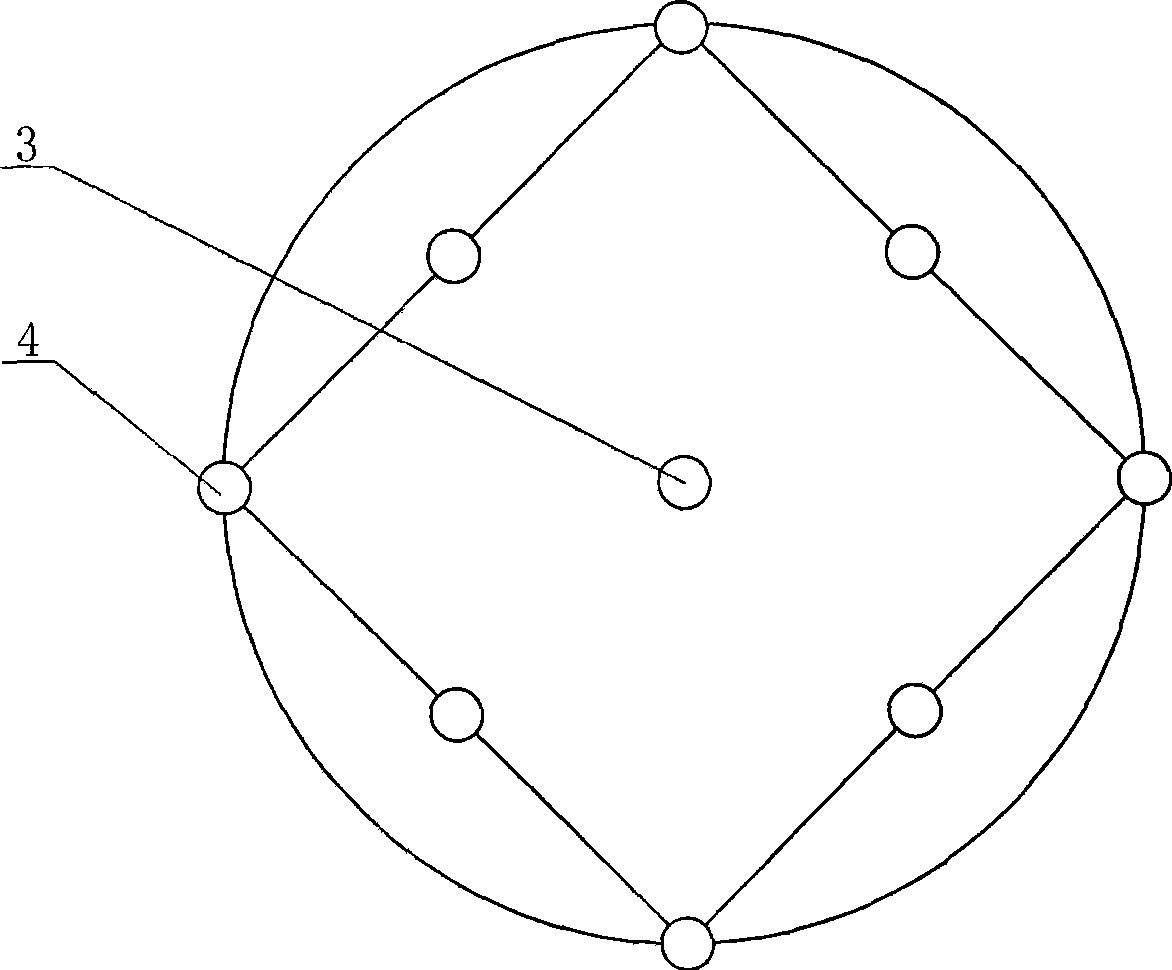

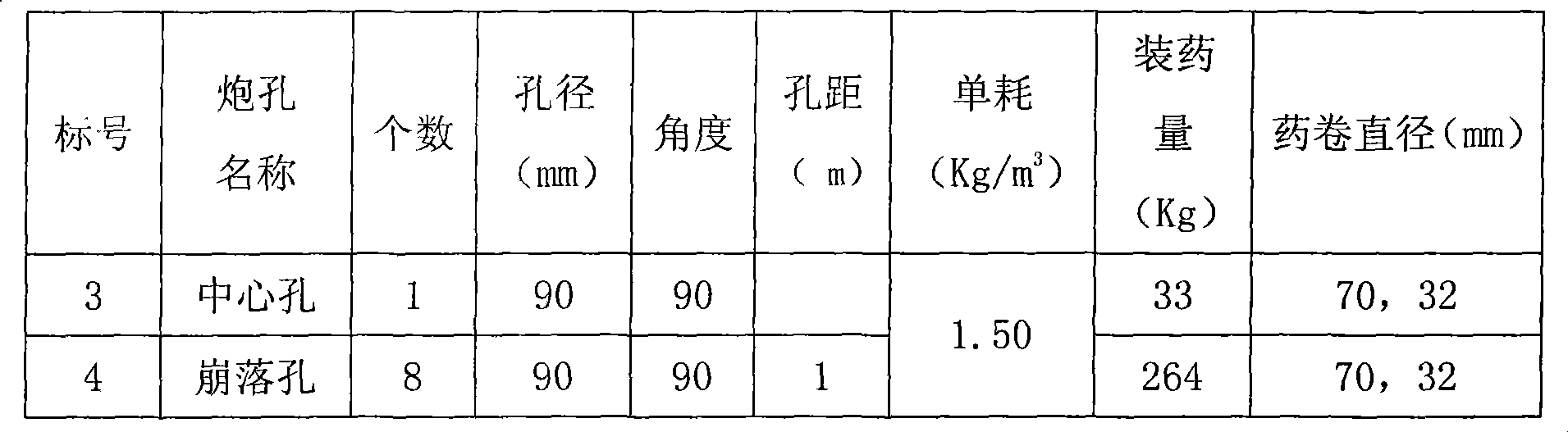

[0018] The surge shaft of Chahan Wusu Hydropower Station in Xinjiang is 71.6m deep, and the excavation diameter is 30m. The rocks are all phyllite sandwiched rocks. The rocks are broken and cracks are developed. It is difficult to install and set up the construction operation platform, and the rock is broken, the pieces are seriously dropped, and the safety protection is difficult. Therefore, when the pilot shaft is excavated from bottom to top to the remaining 22m, it is drilled and blasted from top to bottom at one time. dig.

[0019] 1) In order to ensure the success of one-time drilling and blasting, it is necessary to excavate the lower part of the well and the hole to form a space similar to the blasting surface, so as to ensure that the blasting ballast will collapse in layers during the blasting process. In this example, the lower part has been excavated 49.6 meters meet the construction requirements;

[0020] 2) Determine the space position formed in the lower part, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com