Monitoring method for baseboard leakage of oil product storage tank

A technology for tank bottom and leak detection, which is applied in the application of electrical devices to test fluid tightness, etc., can solve the problems of large volume, complex structure and low sensitivity of tank bottom detection equipment, and achieves reduction of economic losses and environmental pollution, and measurement accuracy. High, strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

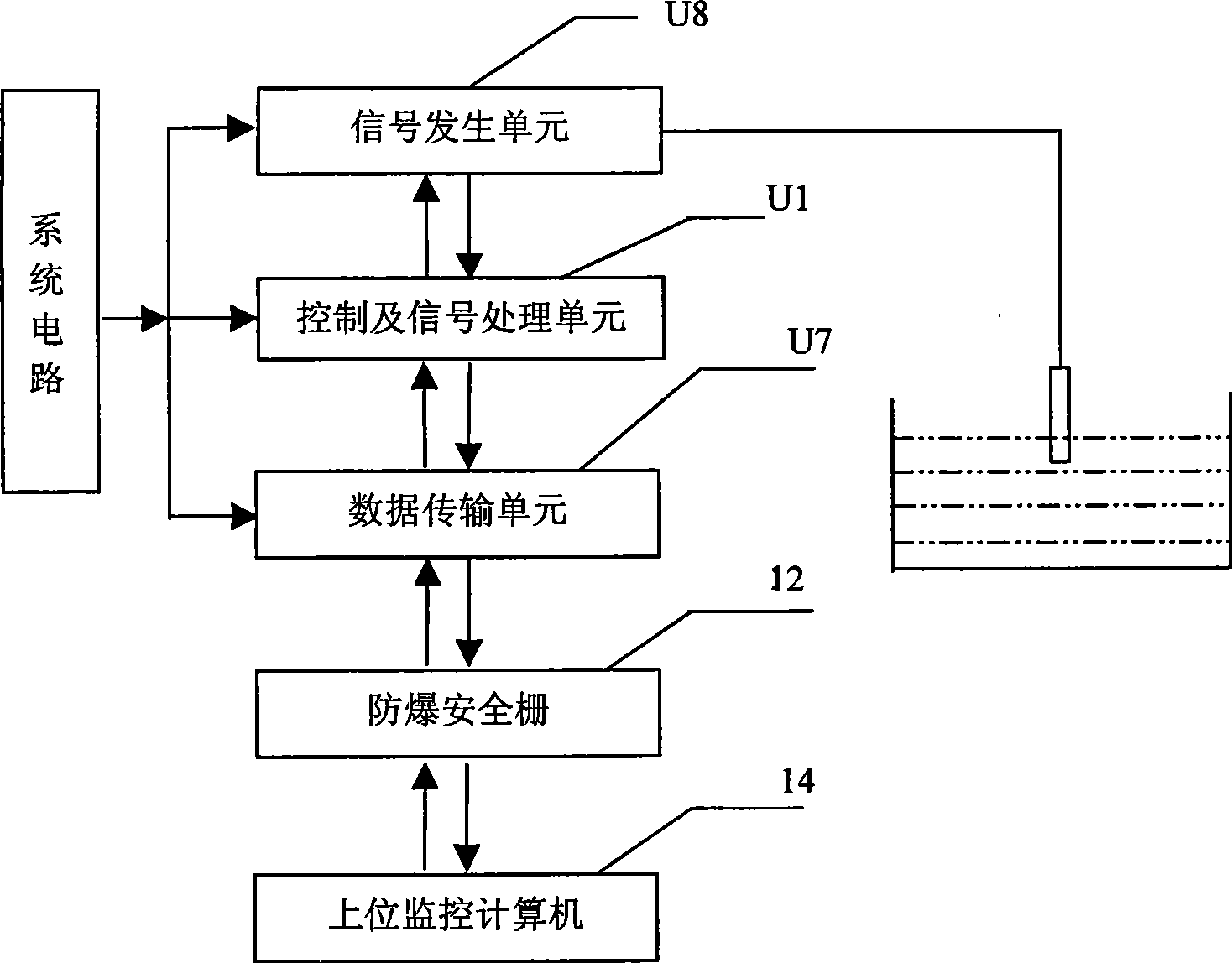

[0034] Such as Figure 8 , 9 As shown, the method of the present invention is realized by the multi-channel industrial monitoring system for oil storage tank bottom plate leakage, adopting 26 alarm detection devices (address numbers are A01~A26), installed in the asphalt sand layer below the oil product storage tank bottom plate, in the The bottom plate of the oil storage tank is evenly arranged within the range covered by the cover, and it can also be arranged in the area corresponding to the bottom plate that is prone to leakage according to the actual situation. Address coding is performed for each alarm detection device to determine the communication address number, and the RS485 bus passes through The explosion-proof safety barrier 12 and the RS485 / 232 conversion unit 13 communicate with the upper monitoring computer 14 .

[0035] Such as image 3 , 4 As shown, the system is composed of an alarm detection device and a host monitoring computer 14, wherein the alarm dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com