Freezing rain preventing insulator

An insulator and freezing rain technology, applied in insulators, electrical components, circuits, etc., can solve problems such as loss, collapse of utility poles, etc., and achieve the effects of avoiding losses, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

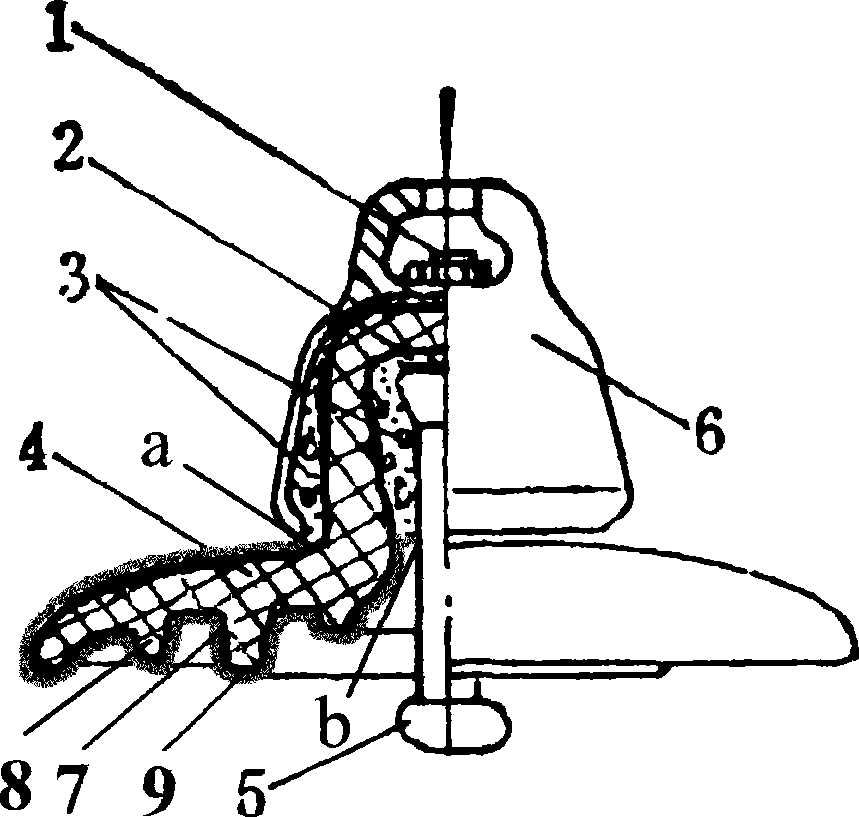

[0017] see figure 1 . According to the surface heating condition of the PTC coating in freezing rain weather or the size of the leakage current, a commercially available PTC ceramic material with a positive temperature coefficient thermistor material with a thermal protection point temperature of 5°C-15°C is selected as the PTC coating 7. The method of spraying is to cover the upper and lower surfaces of the insulating part 4 of the insulator with a PTC coating 7, and the coating thickness gradually becomes thinner from the inside to the outside along the radial direction of the insulating part 4, and the thickness variation range is about 0.25mm-0.05mm. Via this PTC coating 7, the spring pin 1 and the pin connection 5 can be connected. The current flow of the PTC coating 7 is determined by the potential difference between the elastic pin 1 and the pin connection 5 and the temperature of the PTC coating 7 . When the temperature of the PTC coating 7 was lower than the thermos...

Embodiment 2

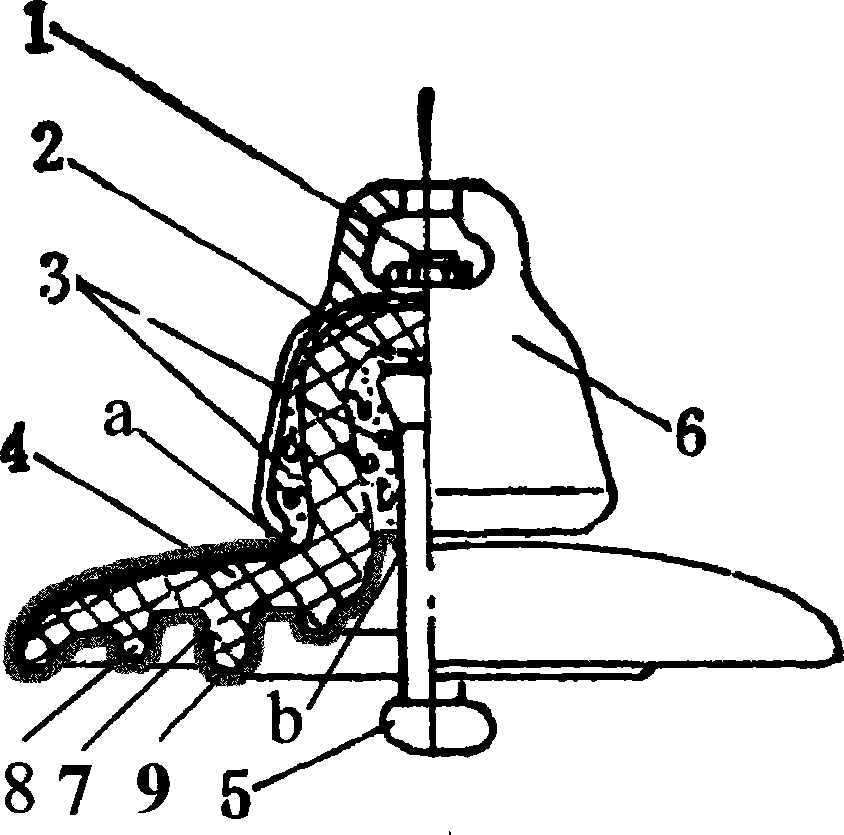

[0019] see figure 2 . In order to make the original insulator have the function of anti-freezing rain disaster, PTC ceramics with a thermal protection point temperature of about 10 ℃ can be selected as the coating material. From the lower edge a of the cap 6 of the insulator to point b along the edge of the skirt 8 of the insulator 4 by means of high-temperature spraying, spray a positive temperature coefficient heat-sensitive material PTC coating 7, and the thickness of the coating is along the radial direction of the insulator 4. It gradually becomes thinner from the inside to the outside, and the thickness range is about 0.25mm-0.05mm. The metal cap 6 of the insulator and the pin connection 5 can be connected via this PTC coating 7 . The current flow of the PTC coating 7 is determined by the potential difference between the elastic pin 1 and the pin connection 5 and the temperature of the PTC coating 7 itself. When the temperature of the PTC coating 7 is lower than the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com