Flat linear vibrating motor

A linear vibration, flat technology, applied in the direction of electromechanical devices, electrical components, synchronous machine parts, etc., can solve the problems of increasing the height of the motor, unfavorable thin development, etc., and achieve the effect of reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] The invention is a flat linear vibrating motor, which is mainly used in consumer electronic products such as mobile phones and handheld game machines.

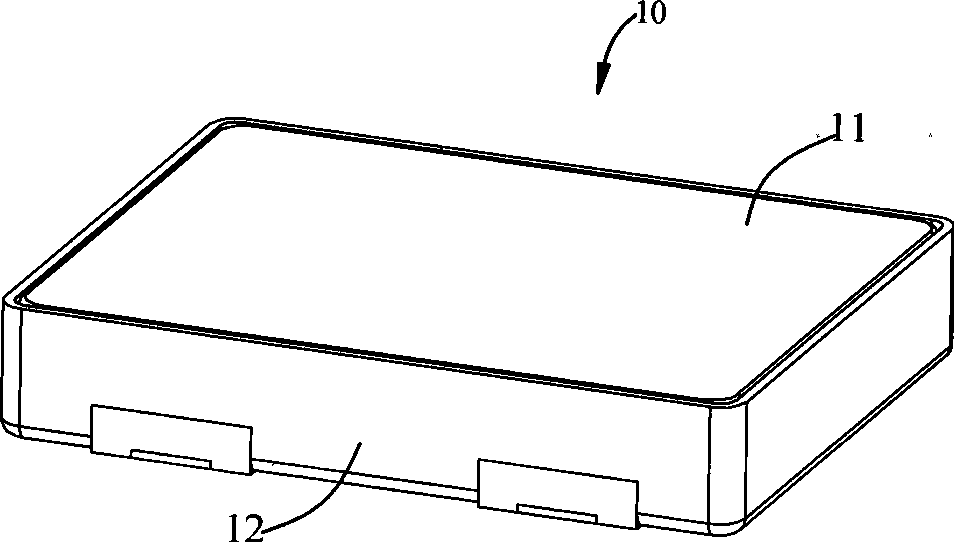

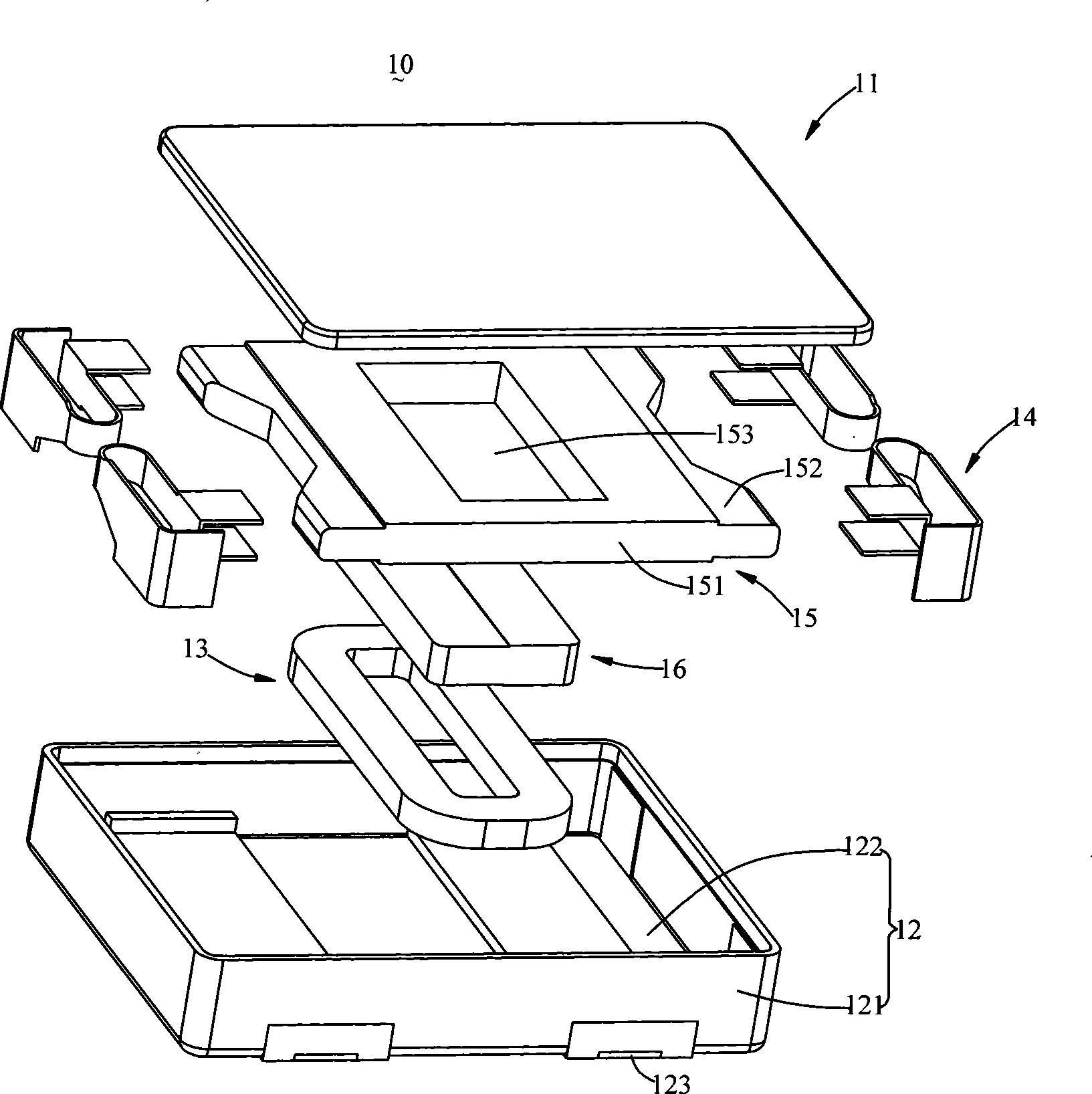

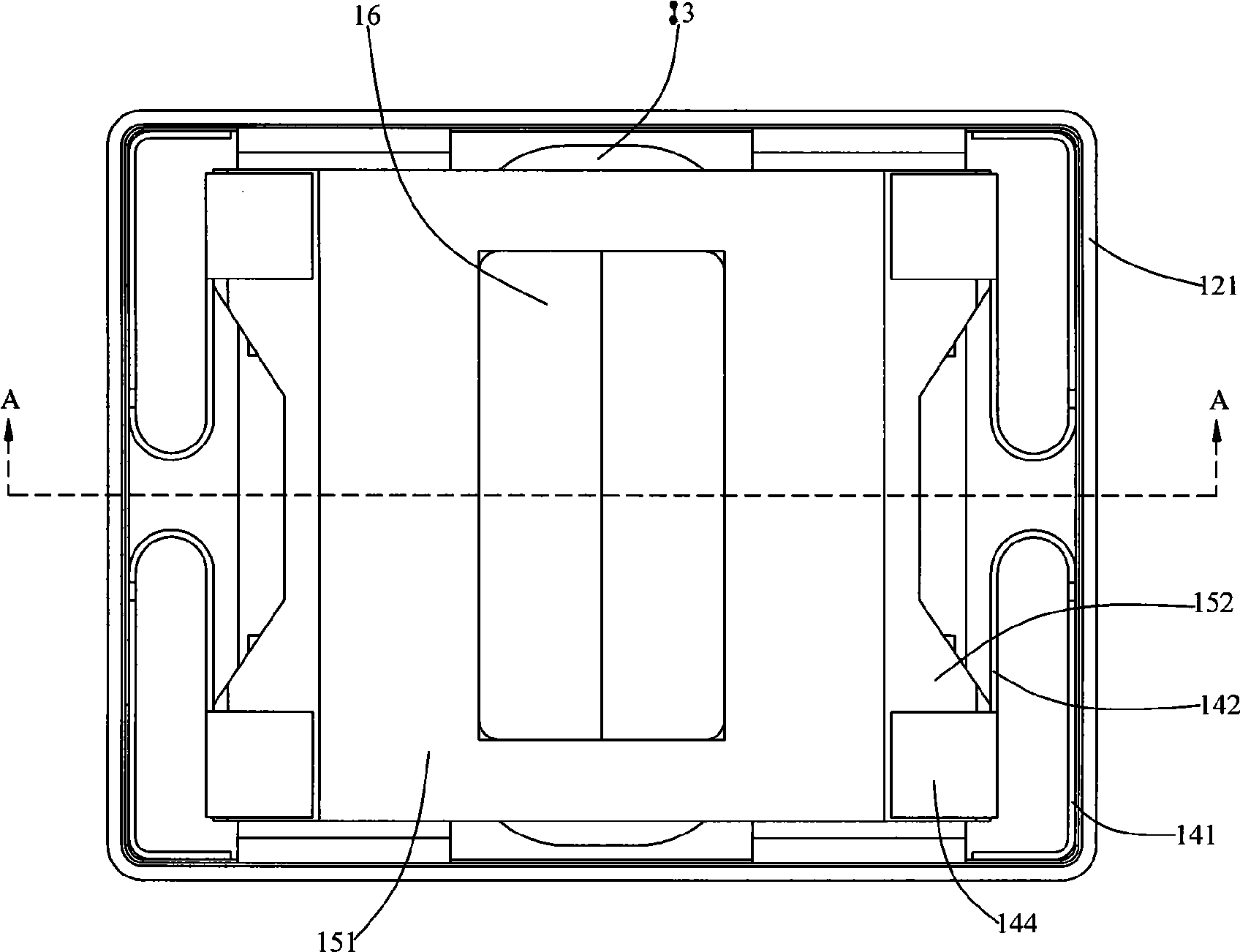

[0026] Please refer to Figure 1 to Figure 3 , the flat linear vibration motor 10 includes an upper cover 11 , a base 12 assembled with the upper cover 11 to form an accommodation space, an annular coil 13 , several elastic supports 14 , counterweights 15 and permanent magnets 16 .

[0027] The base 12 is provided with a plurality of side walls 121 and a bottom wall 122 vertically connected to the side walls 121. The coil 13 is positioned on the bottom wall 122 and its coil leads (not shown) are welded to the conductive sheet 123 positioned on the bottom wall 122. , in order to obtain alternating current from the outside, the elastic support 14 is positioned on the base 12, preferably on the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com