Improved brewing process

A beer, specific technology, applied in the field of proline-specific protease, accelerated fermentation beer, can solve the problems of time-consuming, no accelerated beer stabilization period, shortened beer maturation period, etc., to minimize waste liquid flow, oxygen exposure The effect of risk reduction and self-antioxidant improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Example 1 Pilot Scale Beer Production

[0092] Two pure malts were brewed under the same conditions in a 20 hl semi-industrial pilot plant at the IFBM (Institute Francais de la Brasserie et de la Malterie, Vandoeuvre-les-Nancy, France) brewery. To one of these malts was added a proline-specific protease (Brewers Clarex from DSM Food Specialties, Delft, TheNetherlands, containing 5 PPU / g product) at a concentration of 10 PPU / hl of malt during fermentation and at 4500 ADU at the start of fermentation. At a concentration per hectoliter of malt, acetolactate decarboxylase (Maturex L from NOVO, Bagscaerd, Denmark, containing 1,500 ADU / gram of product) was added. This fermentation is called "trial fermentation". Another malt was similarly fermented and referred to as the "control ferment".

[0093] brewing

[0094] The brew is made from 300kg of barley malt and hop pellets. The starch saccharification condition was 1:4 water: malt ratio (vol / wt), pH 5.6. The starch sac...

Embodiment 2

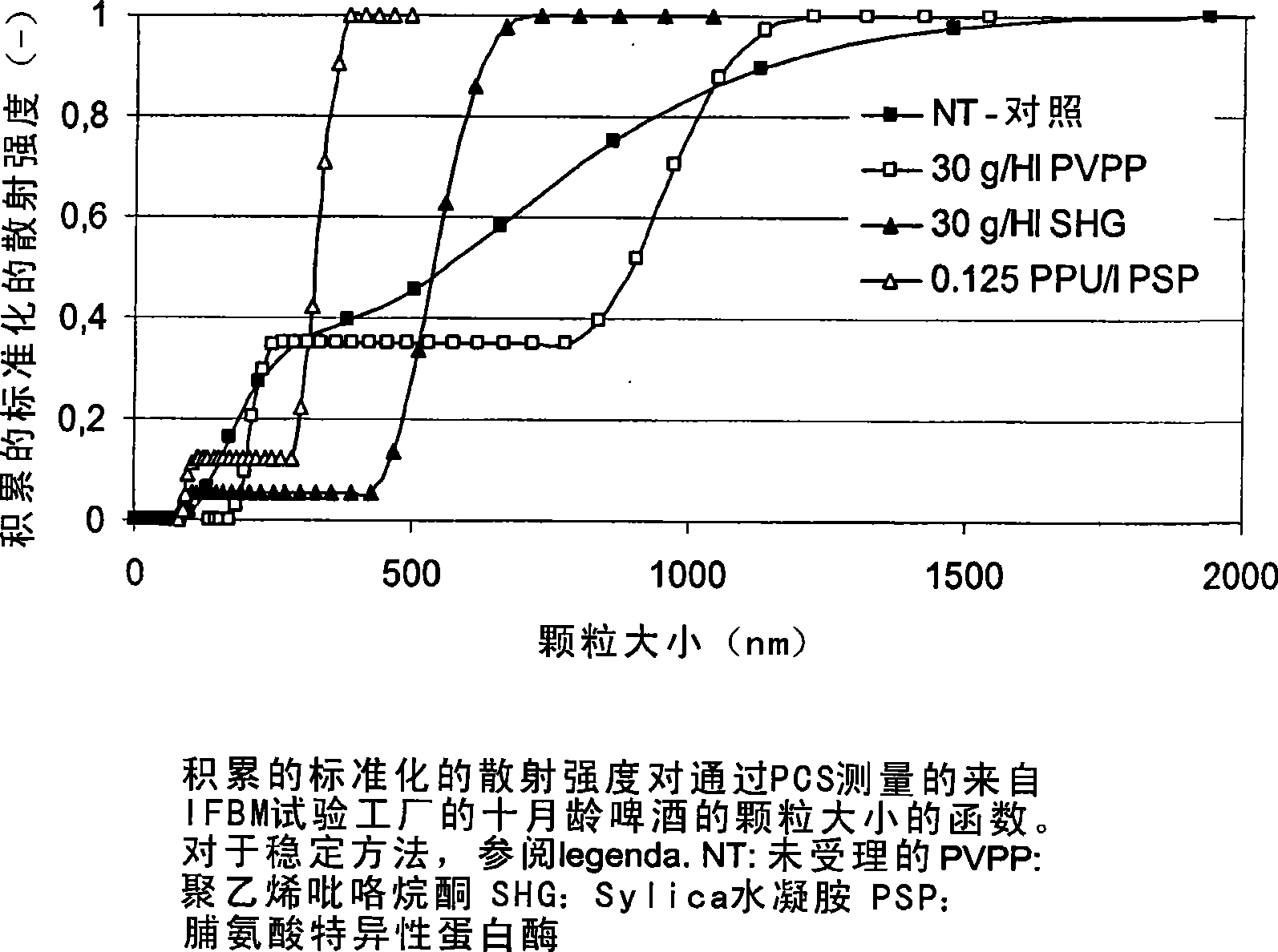

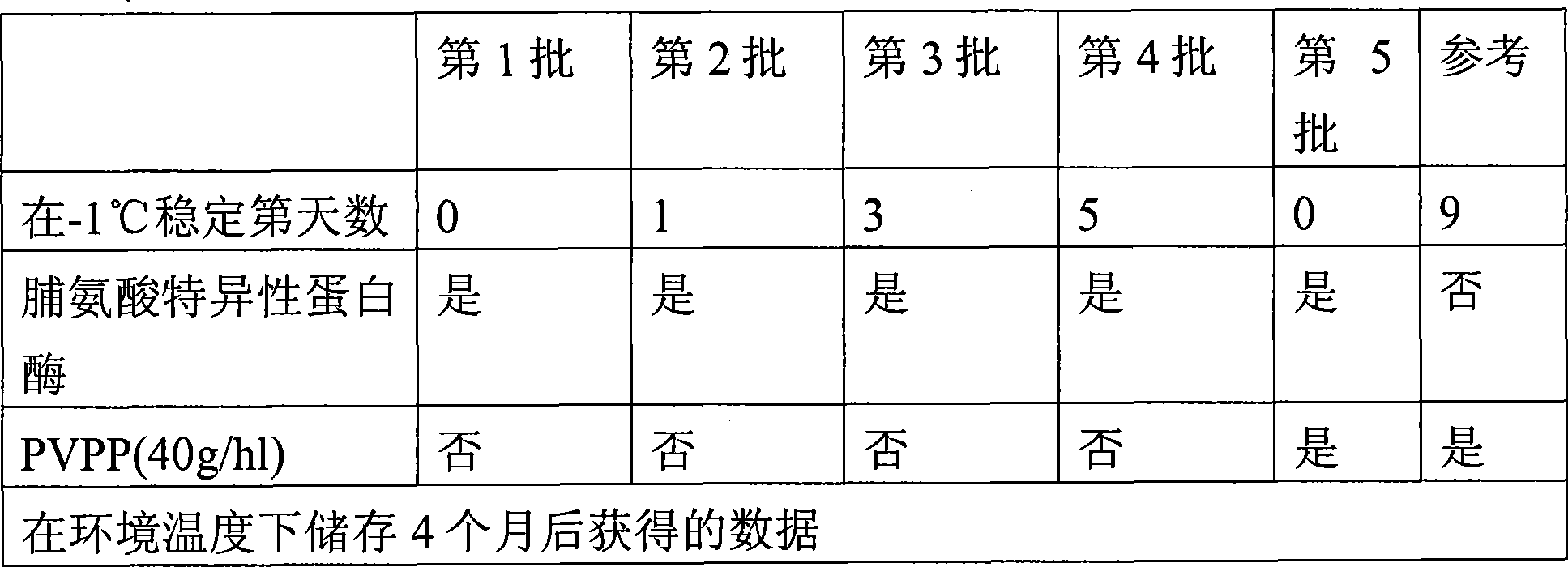

[0105] Example 2 Shortening the Cold Stability Period and Its Effect on the Clarity of an Enzyme-Stabilized, 100% Malt Beer

[0106] Brewing trials were performed to evaluate the effect of proline-specific proteases on 100% malt beer by using a shortened cooling period. For this, six different worts were prepared and fermented according to exactly the same protocol (see "Materials and methods"). Proline-specific protease from Aspergillus niger was added to five fermenters at a concentration of 0.125 PPU / L (see "Materials and Methods" for definition of activity), and in all five fermentations, the enzyme was added to cold water prior to inoculation. in wort. The sixth fermentation was used as a reference, and no proline-specific protease was added. All fermenters were inoculated with fresh storage yeast (approximately 17 million cells / ml wort) and fermentations were carried out at 12°C up to 5plato, then the temperature was raised up to 14°C for the removal of ortho-diketon...

Embodiment 3

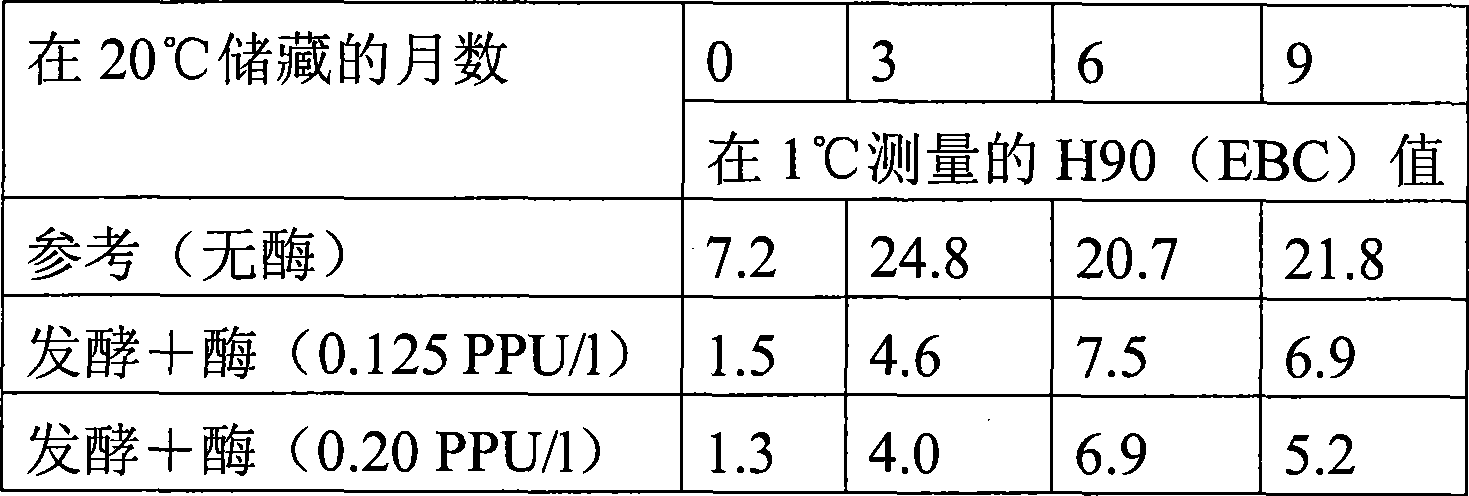

[0115] Example 3 Turbidity Measurement and Haze Formation

[0116] Three 20H1 fermentations were performed on 100% wort of 12Plato according to the procedure described in Example 2. The first fermentation (reference) was fermented without addition of proline-specific protease. The proline-specific protease from A. niger was added to two other fermentations at concentrations of 0.125 and 0.20 PPU / l at the time of inoculation. At the end of maturation (in this case 9 days after the start of fermentation), all three beers were cold stabilized at 1° C. for 5 days, after which yeast and cold precipitates were removed. No PVPP treatment, no silicone treatment. All three beers were filtered on diatomaceous earth filters with coarse and fine grade filter layers. The beers were finally bottled and pasteurized at 15 PU before being stored at ambient temperature for shelf life studies.

[0117] After various storage periods the beer was pre-incubated at 1° C. for 24 hours and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com