Cross-flow type cylinder tobacco dryer

A technology of drum drying machine and drum, which is applied in the fields of tobacco preparation, application, tobacco, etc., can solve the problem of uneven treatment intensity, achieve the effects of stable moisture and structure, improved control ability, uniform temperature and moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

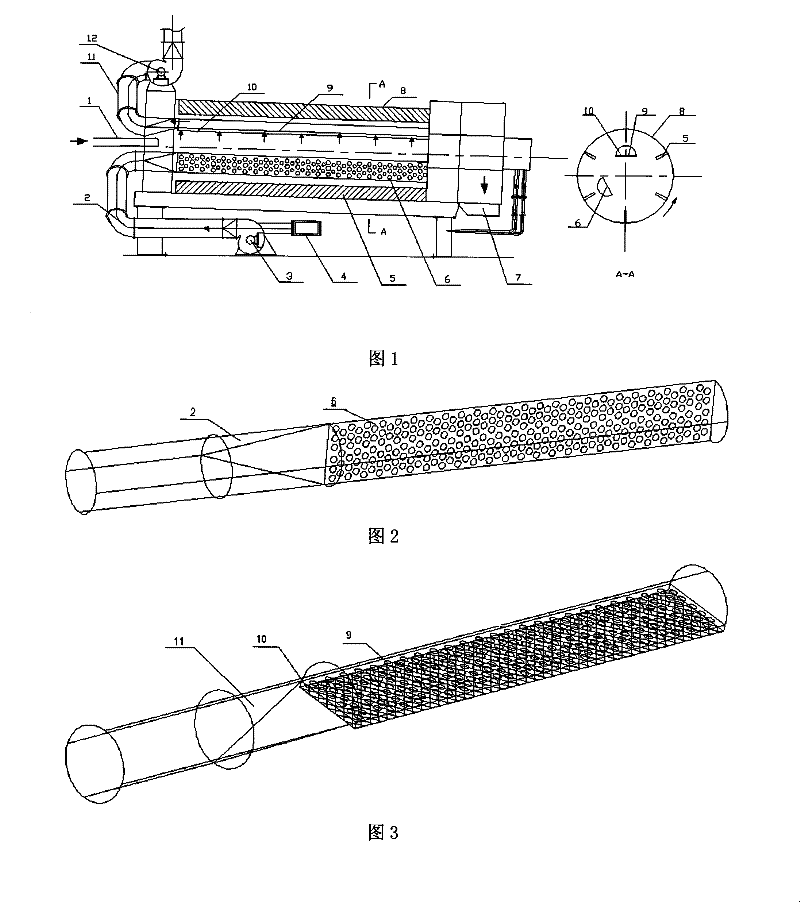

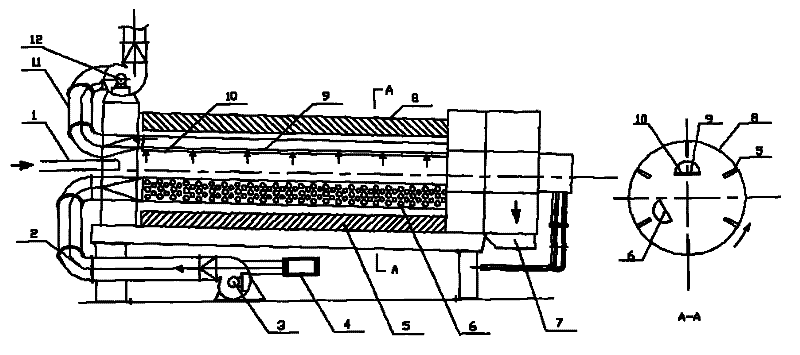

[0015] The present invention is further described below in conjunction with accompanying drawing:

[0016] as attached figure 1 As shown: the cross-flow drum silk drying machine of the present invention includes a drum 8 arranged on a support, a hot air inlet pipeline system and a moisture exhaust pipeline system connected with the inner cavity of the drum, and a cylinder set on the front and rear end faces of the drum. Inlet and outlet ports 1 and 7, wherein: the hot air inlet pipe 2 extends from the bottom of the drum feed port 1, and the hot air pipe air inlet is set at the eight o'clock position in the drum (the side opposite to the shredded tobacco being picked up). The air inlet section has a semicircular groove structure, and the width of the air inlet is equal to the length of the drum. The opening of the air inlet faces the direction of the drum axis to realize radial air intake. The air inlet distribution plate 6 is arranged along the entire air inlet; The connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com