Nonwoven real silk antistatic moistening treatment process

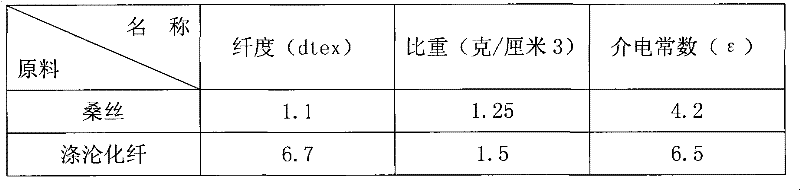

A treatment process and anti-static technology, which is applied in spray/jet textile material treatment, fiber treatment, textiles and papermaking, etc. It can solve the problems of low dielectric constant, hinder the normal operation of equipment, and restrict the normal operation of production lines, etc., to achieve expansion Application fields, the effect of improving grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The following is the production process of non-woven silk products:

[0018] 1. Select the electrolyte and NNO anionic surfactant with good hygroscopicity as the antistatic agent, and prepare the antistatic agent wet solution with a concentration of 2%-3% according to the volume percentage;

[0019] 2. Start the automatic humidification system to control the relative humidity of the production workshop environment at 85%-90%. Because the relative humidity is less than 85%, the moisture in the raw material volatilizes into the air, the moisture regain decreases, and the electrical conductivity decreases accordingly. If the relative humidity is greater than 90%, the silk fibers will be wetted, and the fibers will stick to the parts and be difficult to separate during mechanical processing;

[0020] 3. Spread the 5-8cm degreased and degummed mulberry short fibers in layers in a plastic container of 2m×0.8m×0.4m, and the weight ratio of the mulberry short fibers and the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com