Production system of cyber-physical system type

A production system and systematic technology, applied in manufacturing computing systems, general control systems, control/regulation systems, etc., can solve problems such as increased production time, reduced production quality, and reduced production efficiency of generated workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] (1. Outline of Cyber-Physical Systems Production System)

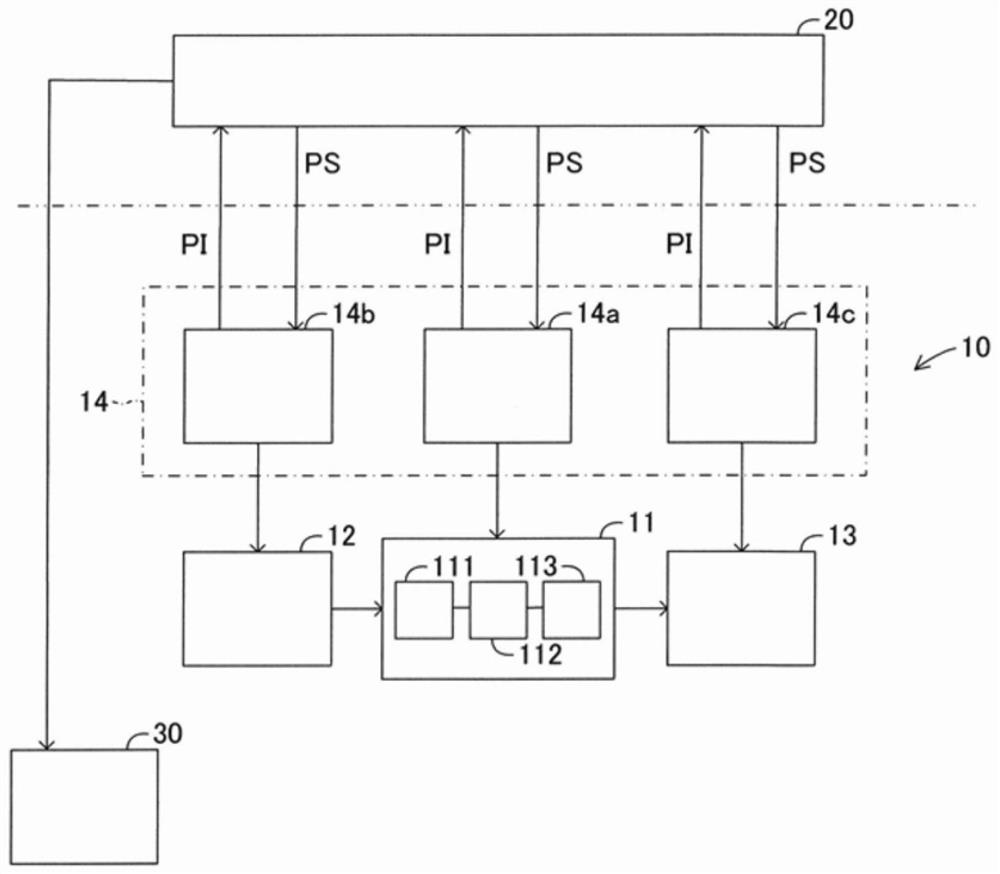

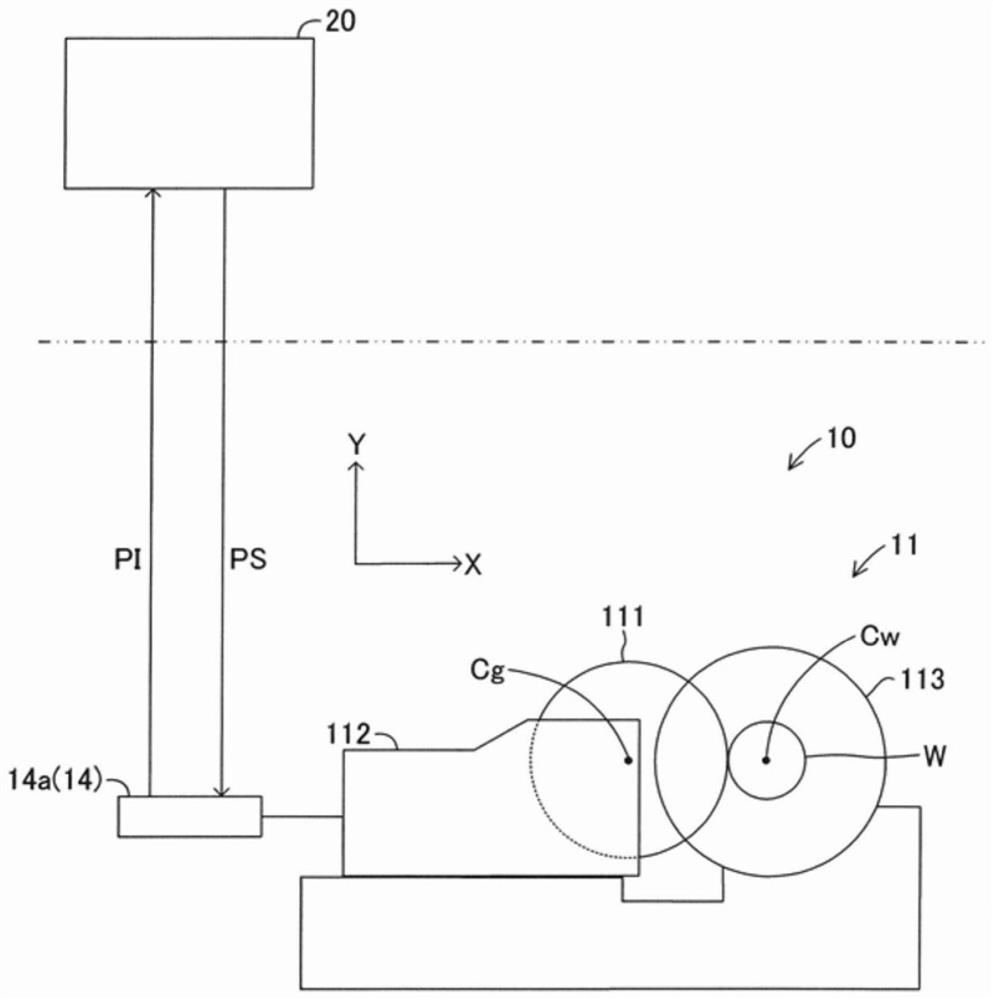

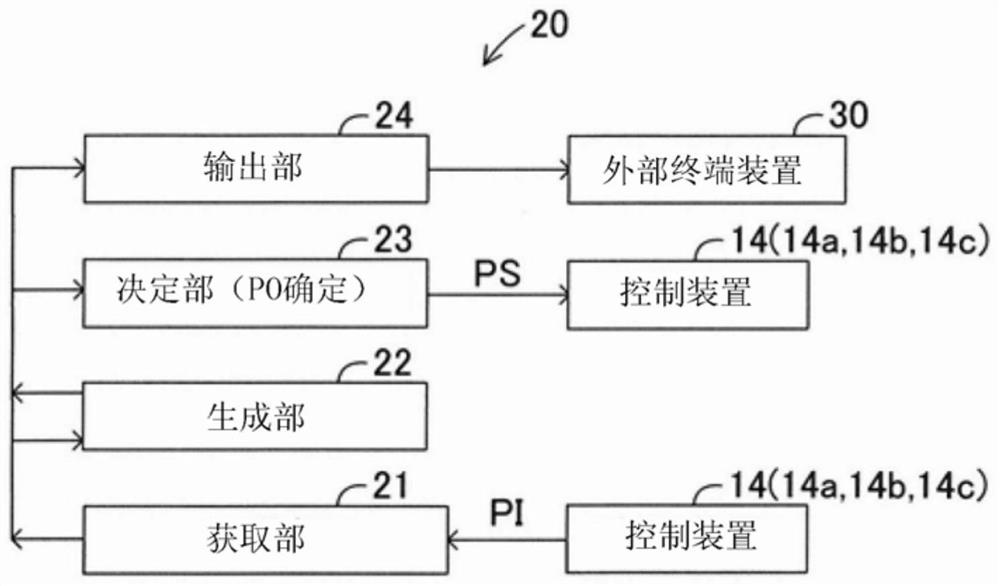

[0016] Hereinafter, a Cyber Physical Production System (Cyber Physical Production System: hereinafter also simply referred to as "CPPS") will be described with reference to the drawings. Such as figure 1 As shown, CPPS (hereinafter, also simply referred to as "production system") includes a production line 10 arranged in the real world and a production line computer device 20 arranged in the virtual world.

[0017] (2. Structure of production line 10)

[0018] The production line 10 includes at least a grinder 11 as a machine tool, a heat treatment furnace 12 arranged upstream of the grinder 11 , and an inspection machine 13 arranged downstream of the grinder 11 as adjacent processing machines to produce workpieces W. In addition, the production line 10 includes a control device 14 that controls the grinder 11 , the heat treatment furnace 12 , and the inspection machine 13 based on the production command v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com