Preparation method of extremely low temperature steel for superconducting magnet protective sleeve of tokamak device

A technology of extremely low temperature steel and superconducting magnets, applied in the field of iron and steel materials, can solve the problems of insufficient performance and high cost, and achieve the effect of reducing alloy cost, reducing alloy cost, and requiring low cooling rate after rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

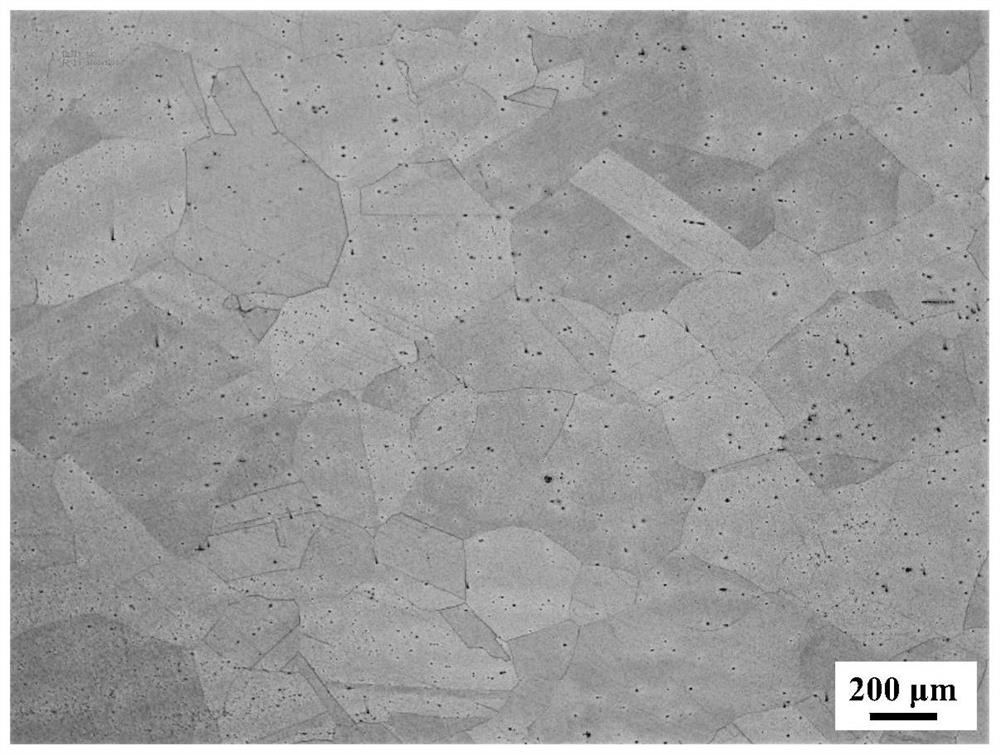

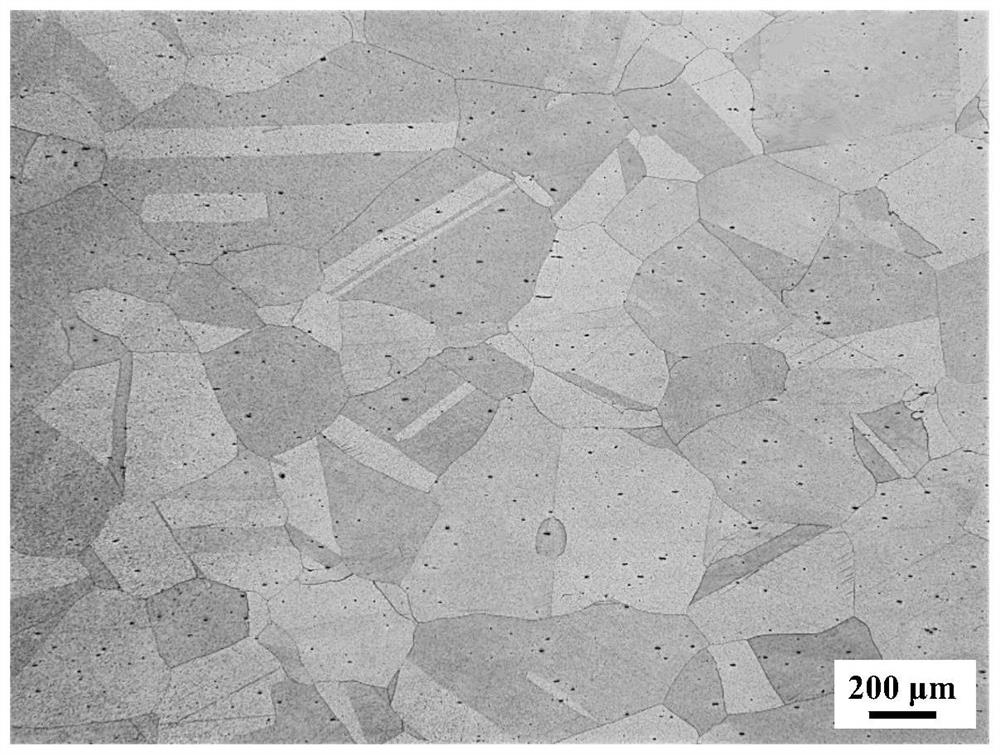

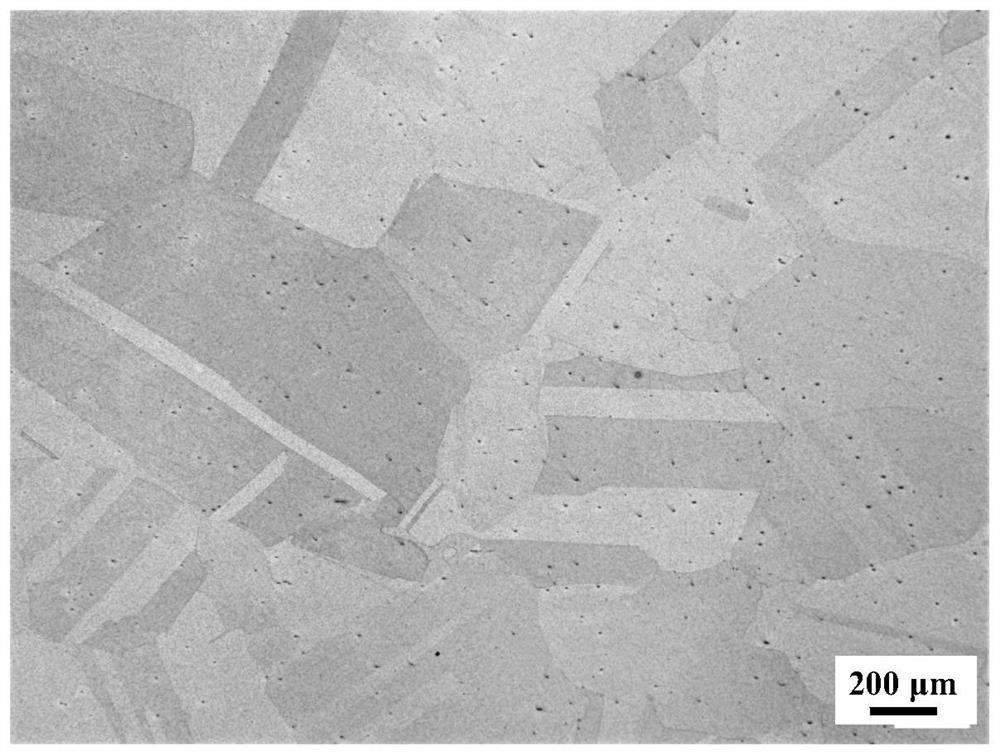

Image

Examples

Embodiment 1-8

[0045] The superconducting magnet protective cover of the tokamak device of the embodiment is made of extremely low temperature steel, and its chemical composition by weight percentage is: C: 0.30-0.61%, Si: 0.12-0.64%, Mn: 16.8-25.2%, Al: 2.0-6.1 %, P≤0.032%, S≤0.017%, the balance is Fe and inevitable impurities. The specific chemical composition of each example is shown in Table 1.

[0046] The preparation method of ultra-low temperature steel for superconducting magnet protective sleeve of tokamak device, the steps are as follows:

[0047] Step 1, casting:

[0048] Smelting is carried out according to the composition ratio of the high manganese steel used for the protective cover of the superconducting magnet of the tokamak device, and the obtained molten steel is poured into a copper mold to obtain a square thin ingot with a thickness of 73mm;

[0049] Step 2, heating:

[0050]Reheat the square ingot to 1100~1200℃, and keep it for 2~4h for homogenization treatment;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com