High-manganese type high-toughness steel applicable to temperature of 4.2 K and preparation method of high-manganese type high-toughness steel

A high-toughness steel and high-manganese technology, which is applied in the field of high-manganese high-toughness steel and its preparation, can solve the problems of insufficient performance and high material cost, and achieve the effects of excellent ultra-low temperature toughness, low control precision requirements, and wide process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

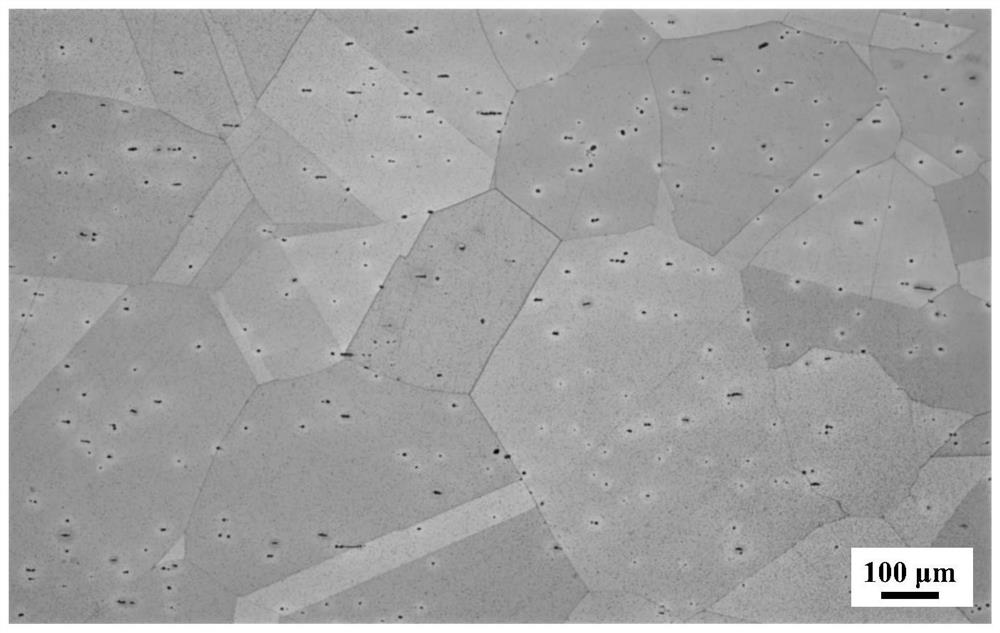

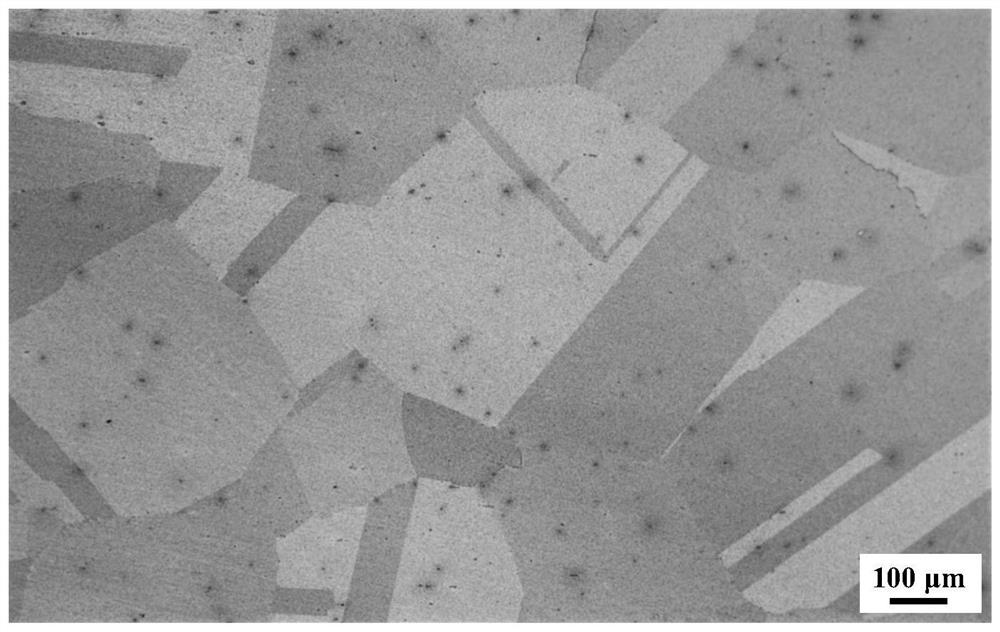

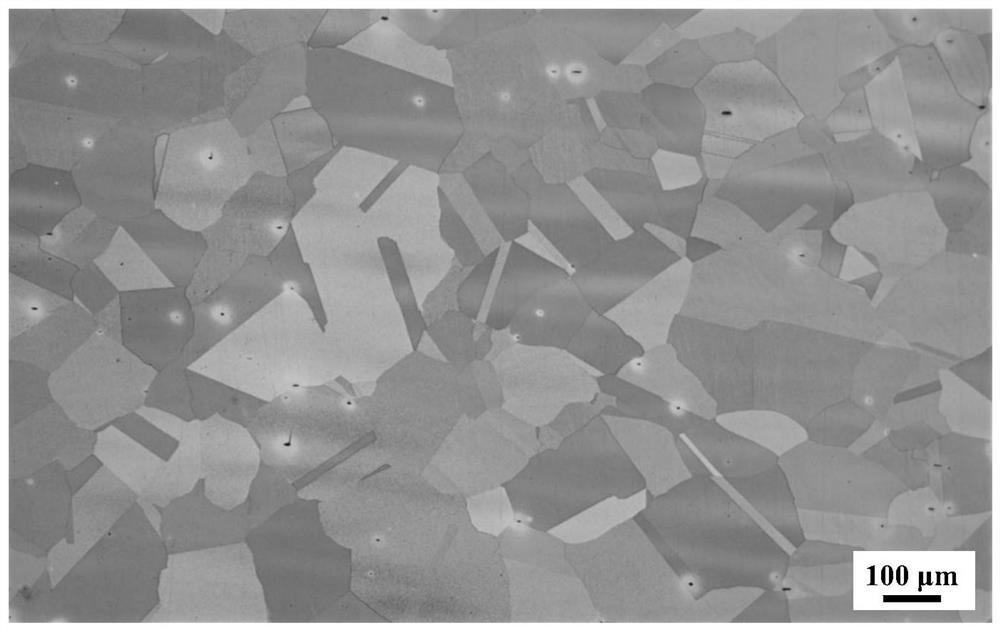

Image

Examples

Embodiment 1-8

[0038] The high-manganese type high-toughness steel applicable at the temperature of 4.2K in the embodiment has the following chemical composition by weight percentage: C: 0.40-0.68%, Si: 0.18-0.54%, Mn: 17.8-24.6%, Al: 0-5.1 %, Cr: 0~5.4%, Cu: 0~0.52%, V: 0~0.27%, Nb: 0~0.24%, P: ≤0.030%, S: ≤0.016%, the balance is Fe and unavoidable Impurities. The specific chemical composition is shown in Table 1.

[0039] The preparation method of the applicable high manganese type high toughness steel under 4.2K temperature, the steps are as follows:

[0040] Step 1, casting:

[0041] Smelting at 1650°C according to the composition ratio of the high-manganese type high-toughness steel applicable at the above-mentioned 4.2K temperature, pouring the obtained molten steel into an iron mold to obtain a square thin ingot with a thickness of 50-74mm;

[0042] Step 2, heating:

[0043] Reheat the square thin ingot to 1200°C and keep it warm for 2 hours;

[0044] Step 3, rolling:

[0045] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com