Double-fuel inlet manifold

An intake manifold, dual-fuel technology, applied in fuel injection device, combustion air/combustion-air treatment, charging system, etc., can solve the problem of unreasonable overall layout of intake manifold, achieve convenient layout, guarantee The effect of fuel injection angle and reasonable arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

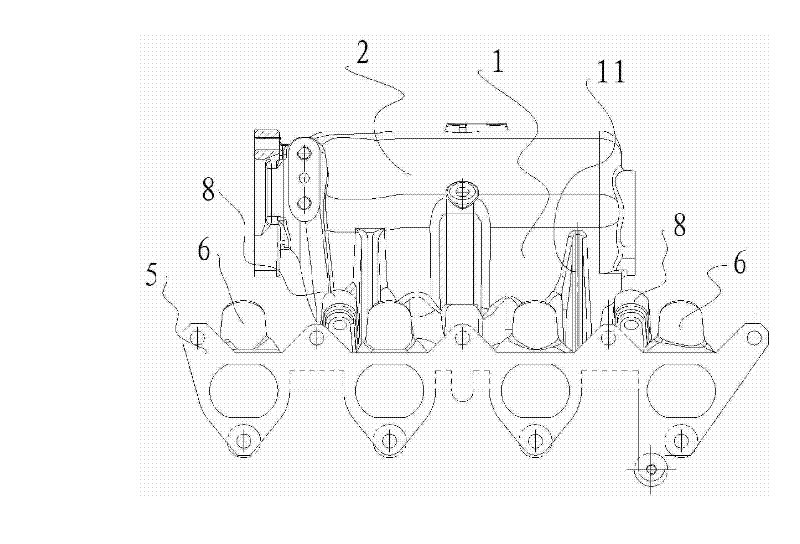

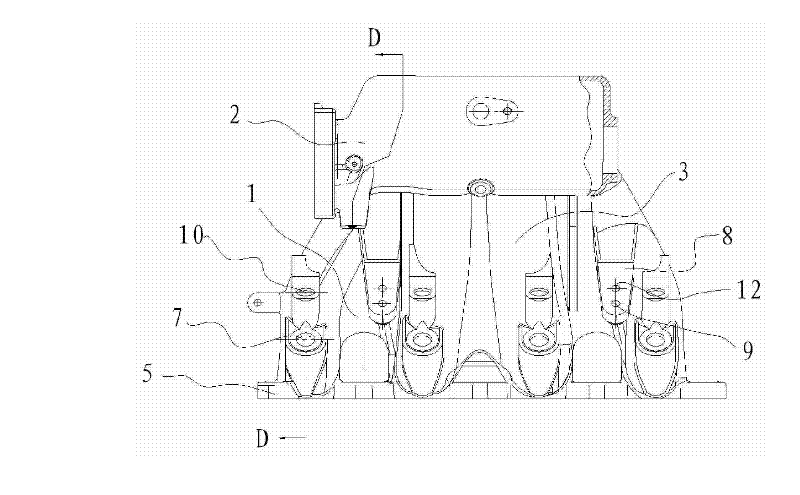

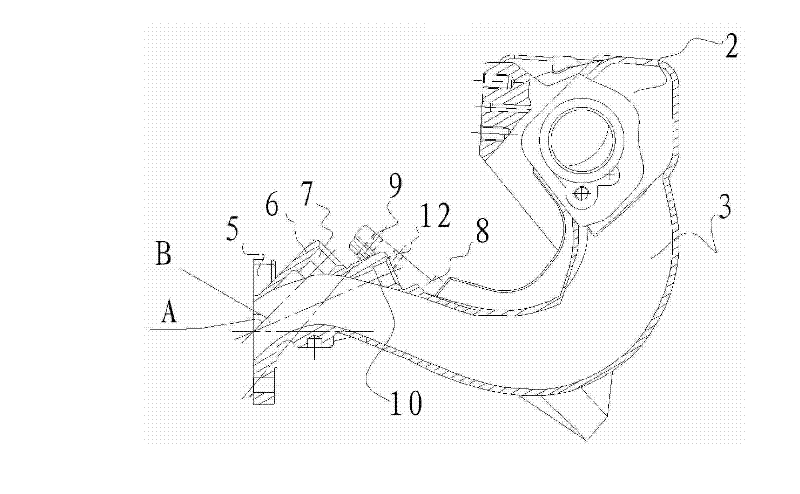

[0020] Such as figure 1 with 2 As shown in and 3, a dual-fuel intake manifold is integrally cast, which includes an intake manifold body 1, and a resonant cavity 2 is arranged on the upper end of the body 1, and the resonant cavity 2 is connected with an inlet There are 4 gas passages 3 and 3 intake passages, and the intake passages 3 are distributed in a claw shape. The main body 1 is provided with an intake manifold connecting seat 5 for connection, which is in the form of a flange, and is used for connecting and fixing the intake manifold and the engine. A fuel nozzle mounting seat 6 integrally cast with the body 1 is provided directly above each air intake channel 3 . Each fuel nozzle mounting seat 6 includes a fuel injection mounting hole 7 in the front row and a fuel injection mounting hole 10 in the rear row. Hole centers coincide. The two installation holes are in the shape of a cylinder, and are arranged in a stepped manner one after the other above the intake air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com