Method and special fixture for improving processed surface toughness of poppet root

A technology for processing surface and roughness, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., to achieve the effect of ensuring processing effect, reliable compression and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

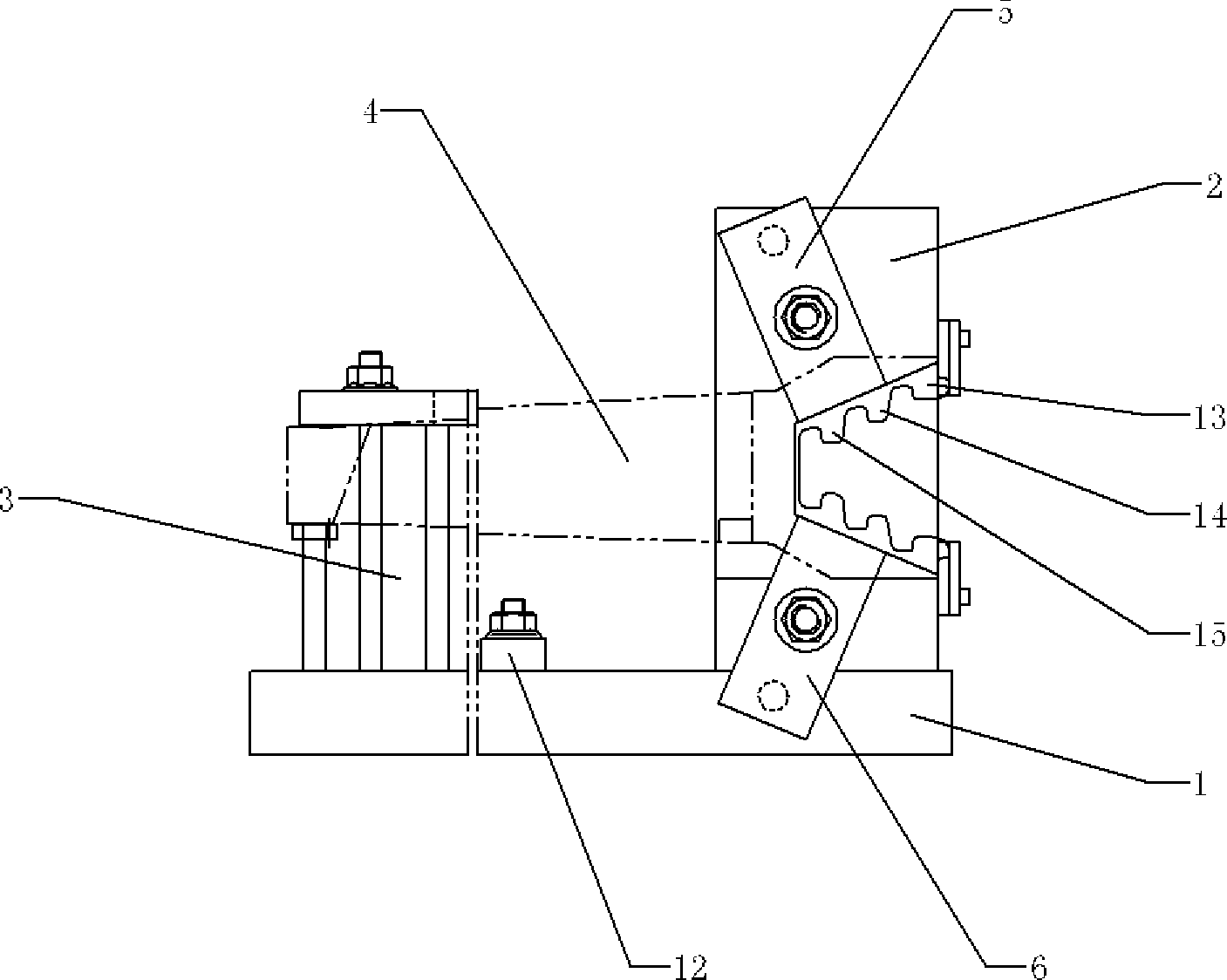

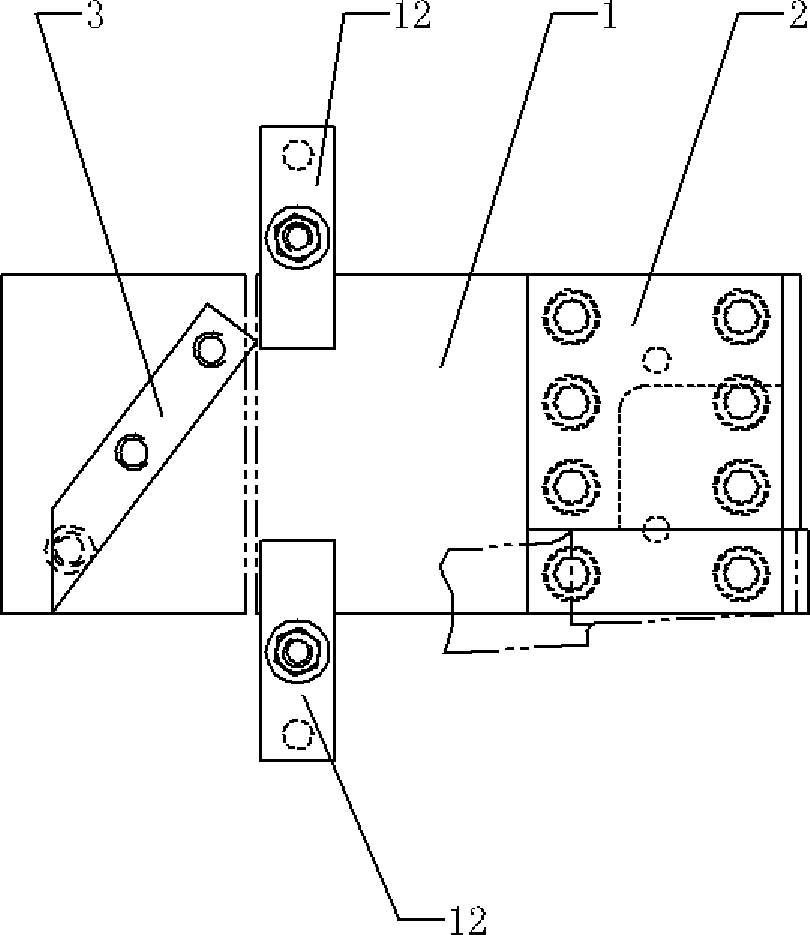

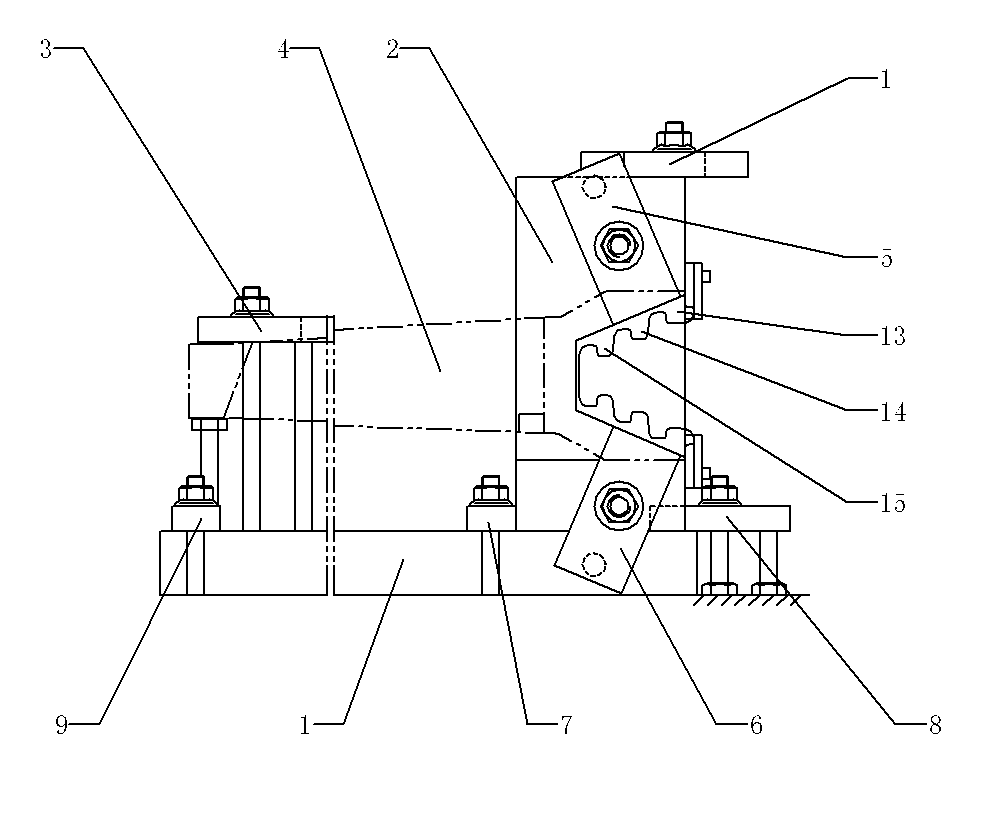

[0019] First, select the forming tool according to the material of the blade and the shape of the blade root, check whether the circular runout of each tooth of the forming tool is within the range of 0-0.015mm and ensure that the roughness of the cutting edge of the tool is Ra0.2μm ~Ra0 .4μm, if the circular runout is out of tolerance, then select the corresponding tool sharpening method according to the circular runout out of tolerance to sharpen the rake face of each tooth of the forming tool, and then determine the rough milling and finishing milling of the blade root The cutting parameters, where the cutting parameters to ensure the rough milling of the blade root is the cutting depth a p =0.1 mm ~0.5mm, feed speed V f =10 mm / min ~15mm / min, the spindle speed n=100 r / min ~130r / min, the cutting parameter of blade root fine milling is cutting depth a p =0.1 mm ~0.3mm, feed speed V f =11 mm / min ~13mm / min, spindle speed n=120 r / min ~130r / min; check the rigidity of the machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com