Method for making lamp strip and the lamp strip

A technology of light strips and light strings, which is applied in the electronic field, can solve the problems of incomplete mechanization and automation of light strips, and complex implementation, and achieve the effect of simple structure, good stability, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

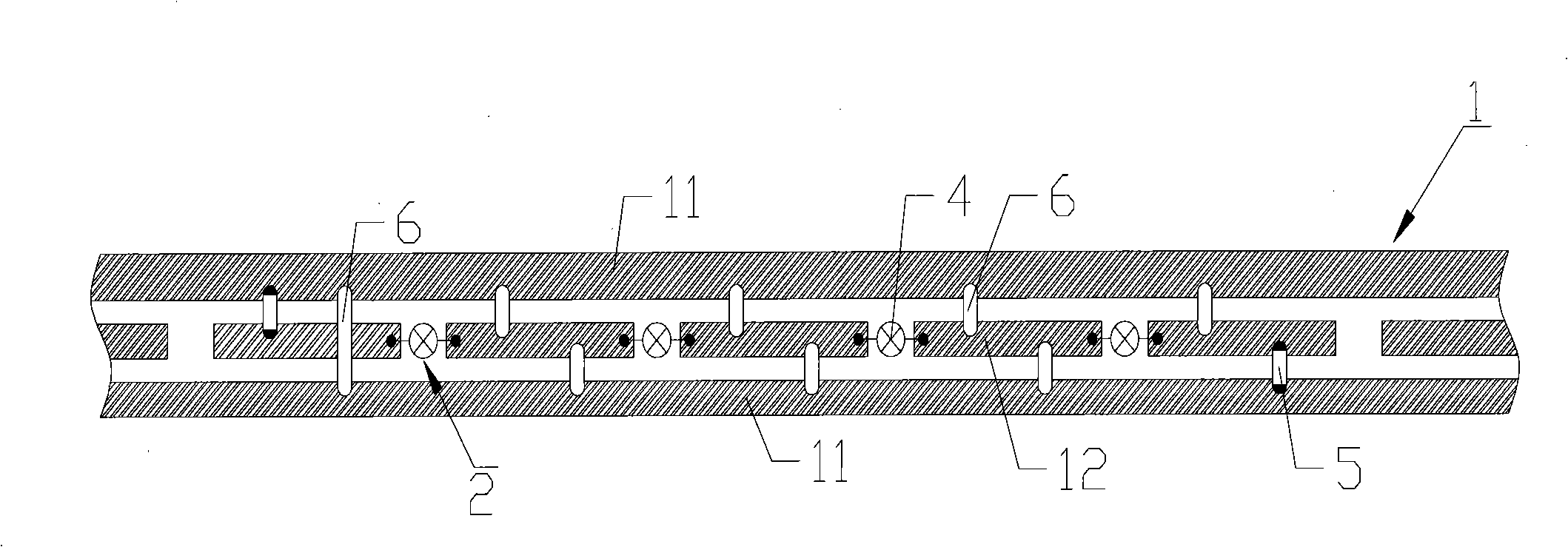

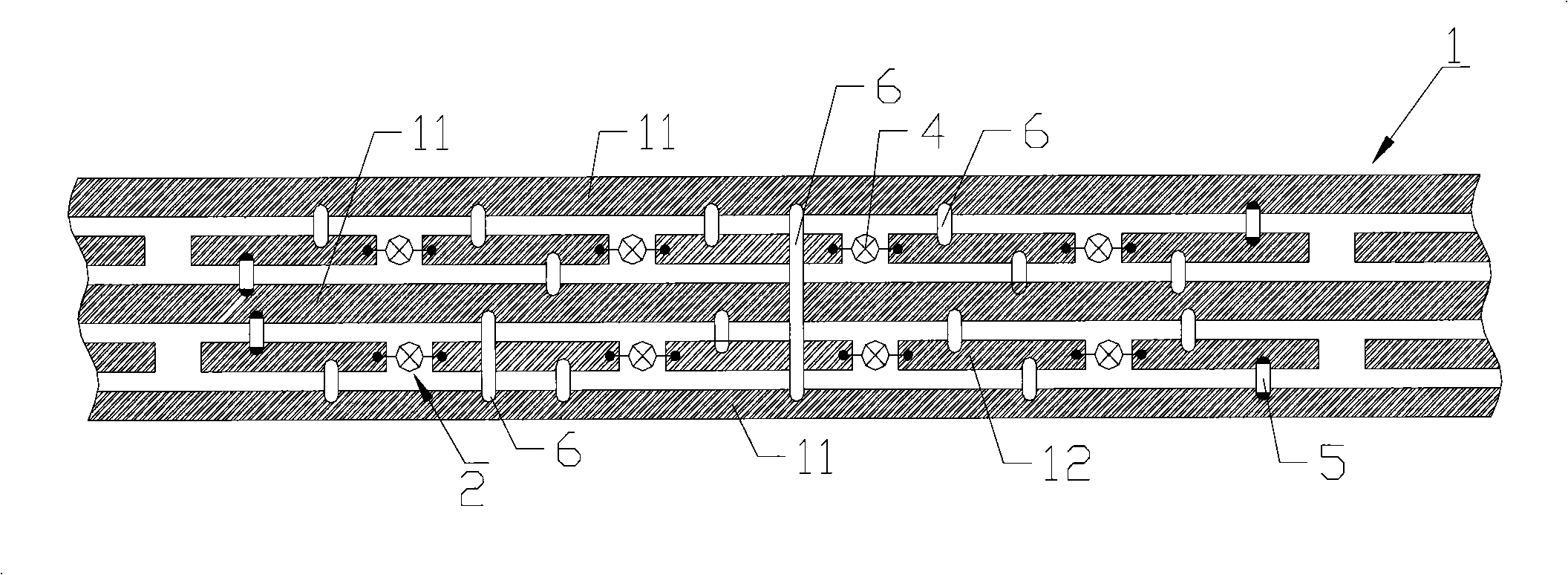

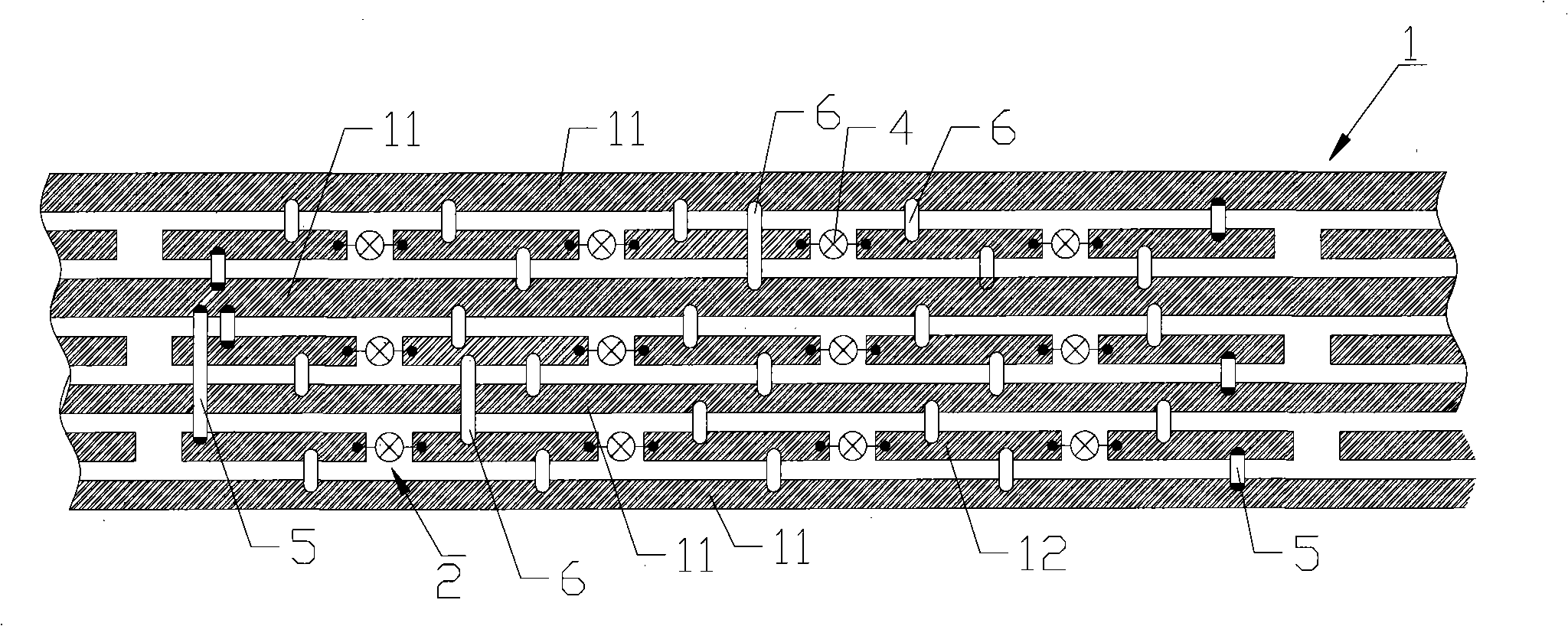

[0051] figure 1 It is a structural schematic diagram of an embodiment of the light strip of the present invention, such as figure 1 As shown, the light strip of this embodiment includes a conductive plate 1, and the conductive plate 1 includes two first conductive strips 11 extending longitudinally as main power lines and a plurality of second conductive strips longitudinally spaced at a certain distance from each other. 12;

[0052]The space between the second conductive strips 12 is welded with a first conductor 4 including a light source, and the first conductor 4 and the second conductive strip 12 form a light string 2; in specific implementation, the first The conductor 4 can be an in-line conductor or a chip-type conductor, and the light source can specifically be a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com