Loop type diffusion winding of turbine generator

A turbogenerator and winding technology, which is applied to the shape/style/structure of winding conductors, can solve problems such as complex manufacturing process, unqualified product performance, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] First, the principle of the scattered winding will be described.

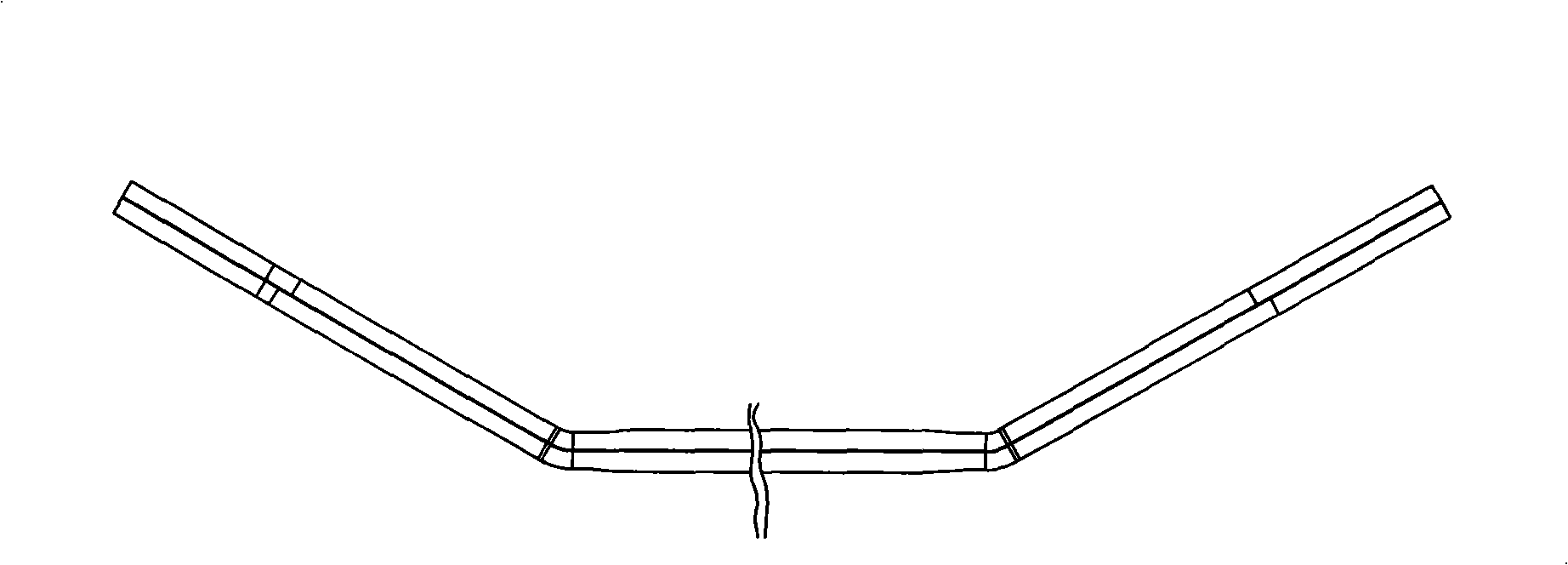

[0029] Lap winding means that any two adjacent coils are stacked on top of the previous coil. In manufacturing, one coil of this winding is mostly manufactured at one time, and this form of coil is also called frame winding.

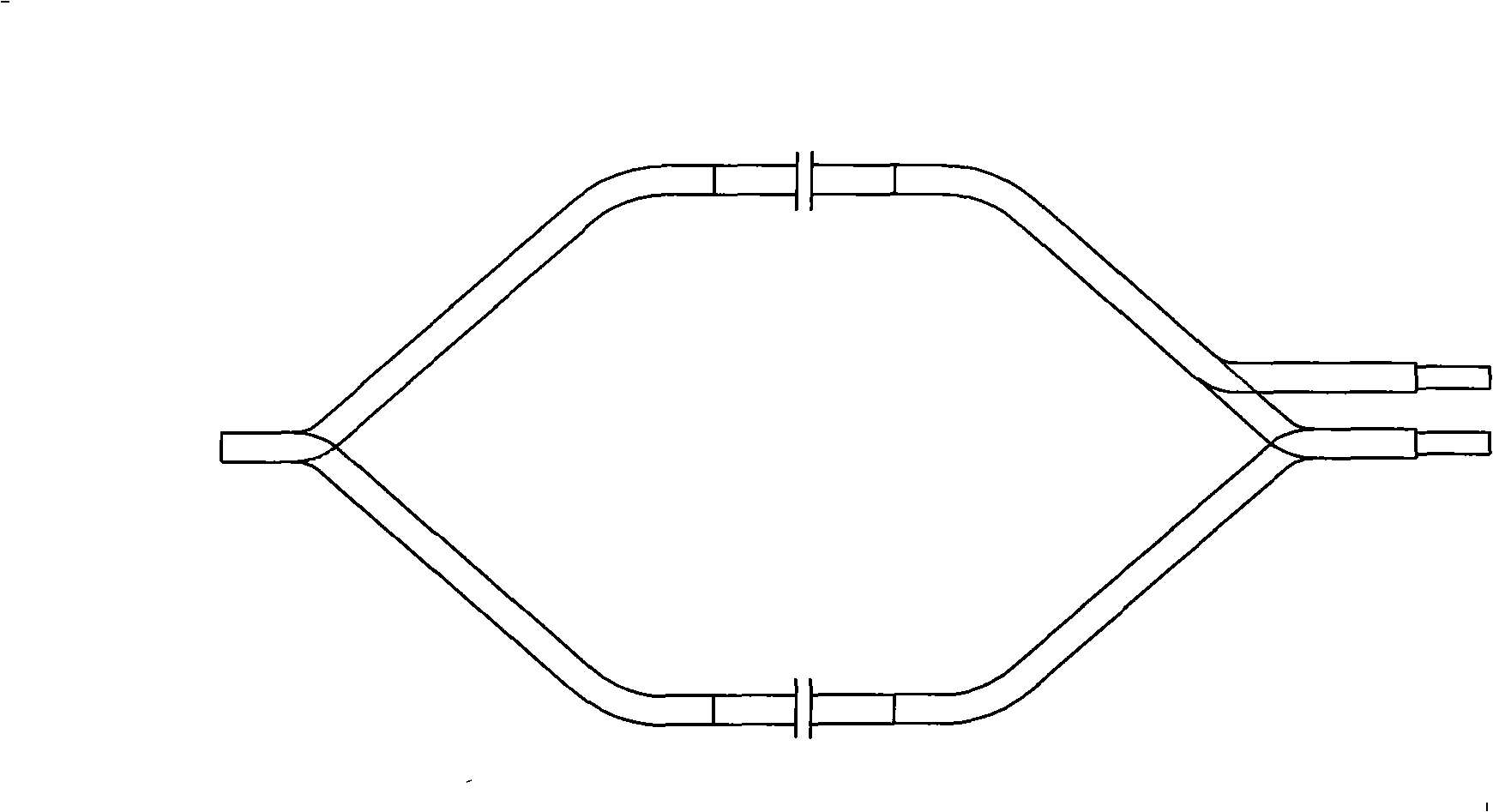

[0030] figure 2 is the structure diagram of a conventional winding.

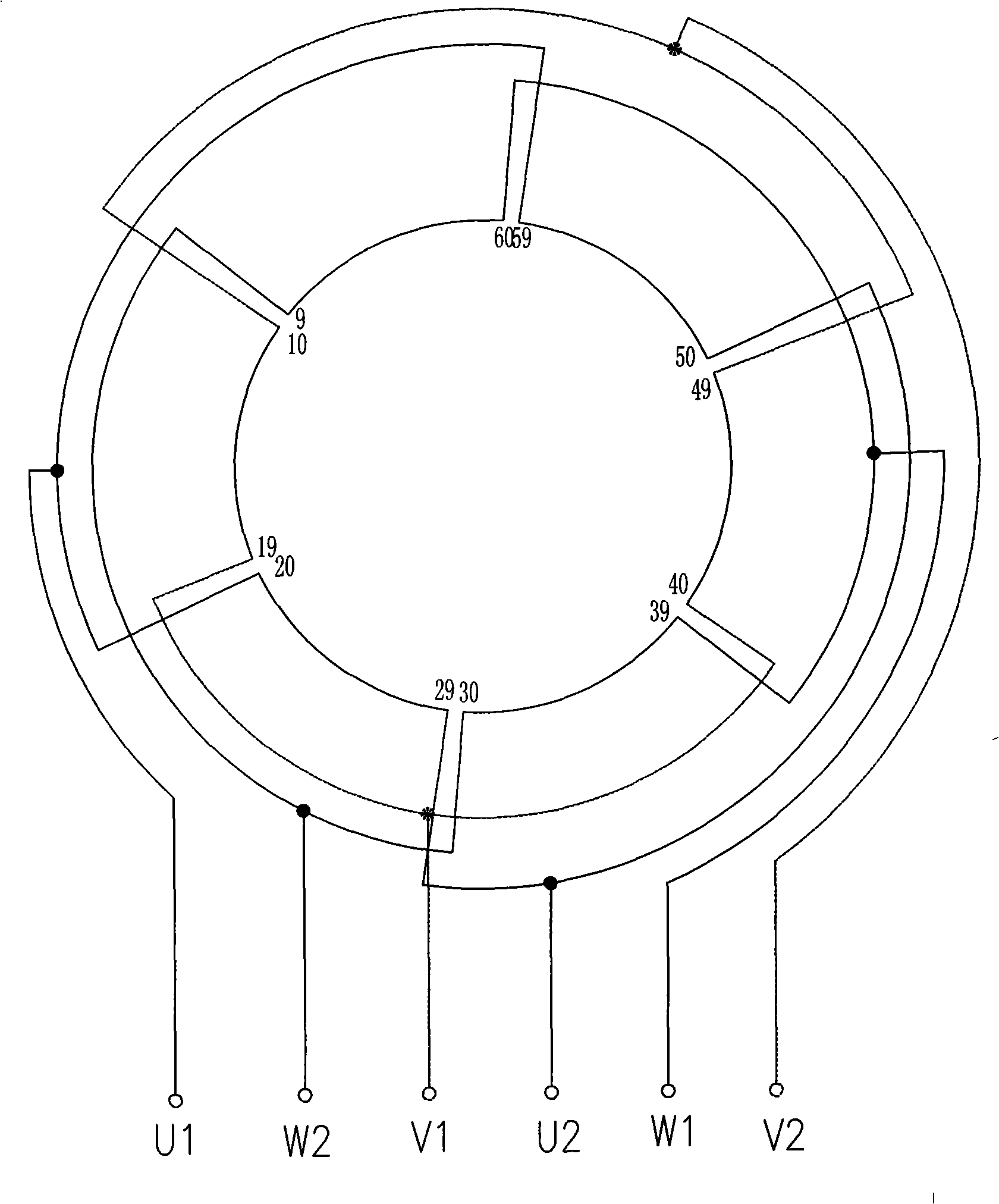

[0031] Figure 4 It is a structural diagram of the present invention.

[0032] Such as figure 2 , Figure 4 As shown, the two windings are stacked windings, three-phase windings, Y connection, 2 poles, and 2 parallel circuits. U1, V1, W1, U2, V2, and W2 are lead-out wires, and the two windings are manufactured counterclockwise when viewed from the wire-out end. When the number of lead-out wires is 3, U2, V2, and W2 are connected internally without leading out; when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com