High critical temperature superconducting article with improved mechanical strength

A product and superconducting technology, applied in the field of superconducting products, can solve problems such as the deterioration of superconducting properties, and achieve the effect of low production cost and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In the following detailed description of exemplary embodiments of the invention, reference is made to the accompanying drawings which form a part hereof, and illustrate specific exemplary embodiments in which the invention may be practiced. Therefore, the present invention is not limited to the following detailed description. In the drawings, the same reference numerals indicate the same or corresponding elements, parts or features, and the like.

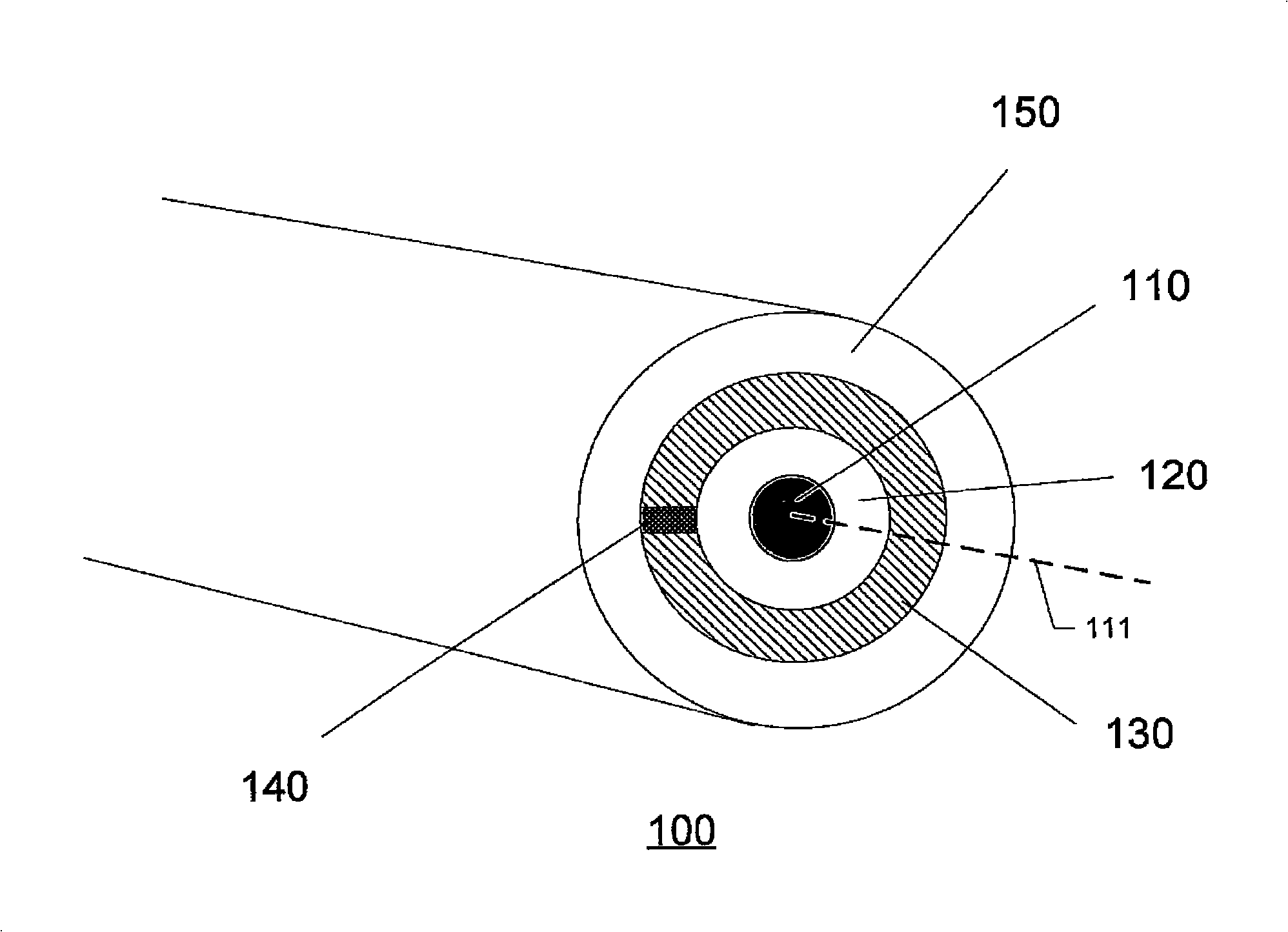

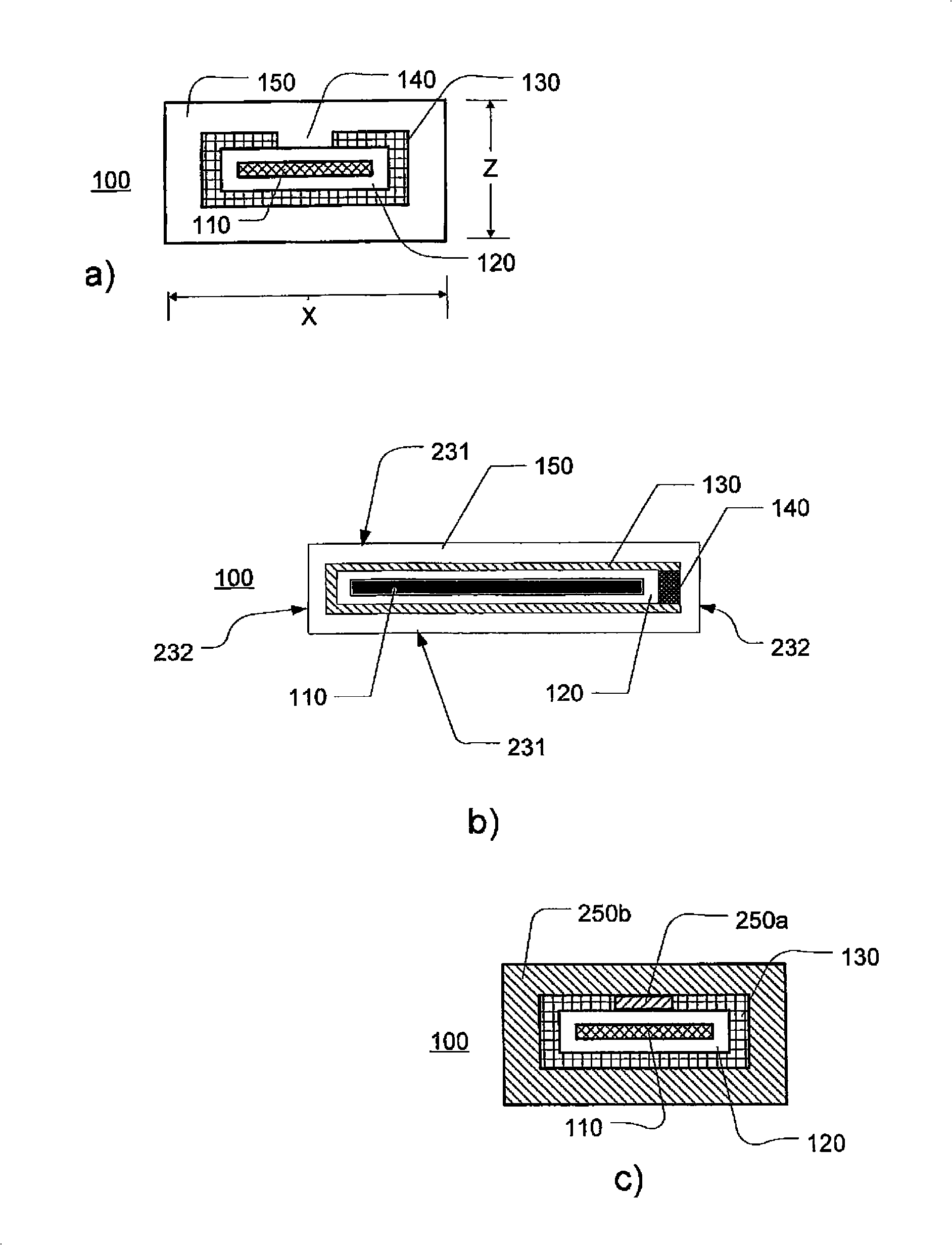

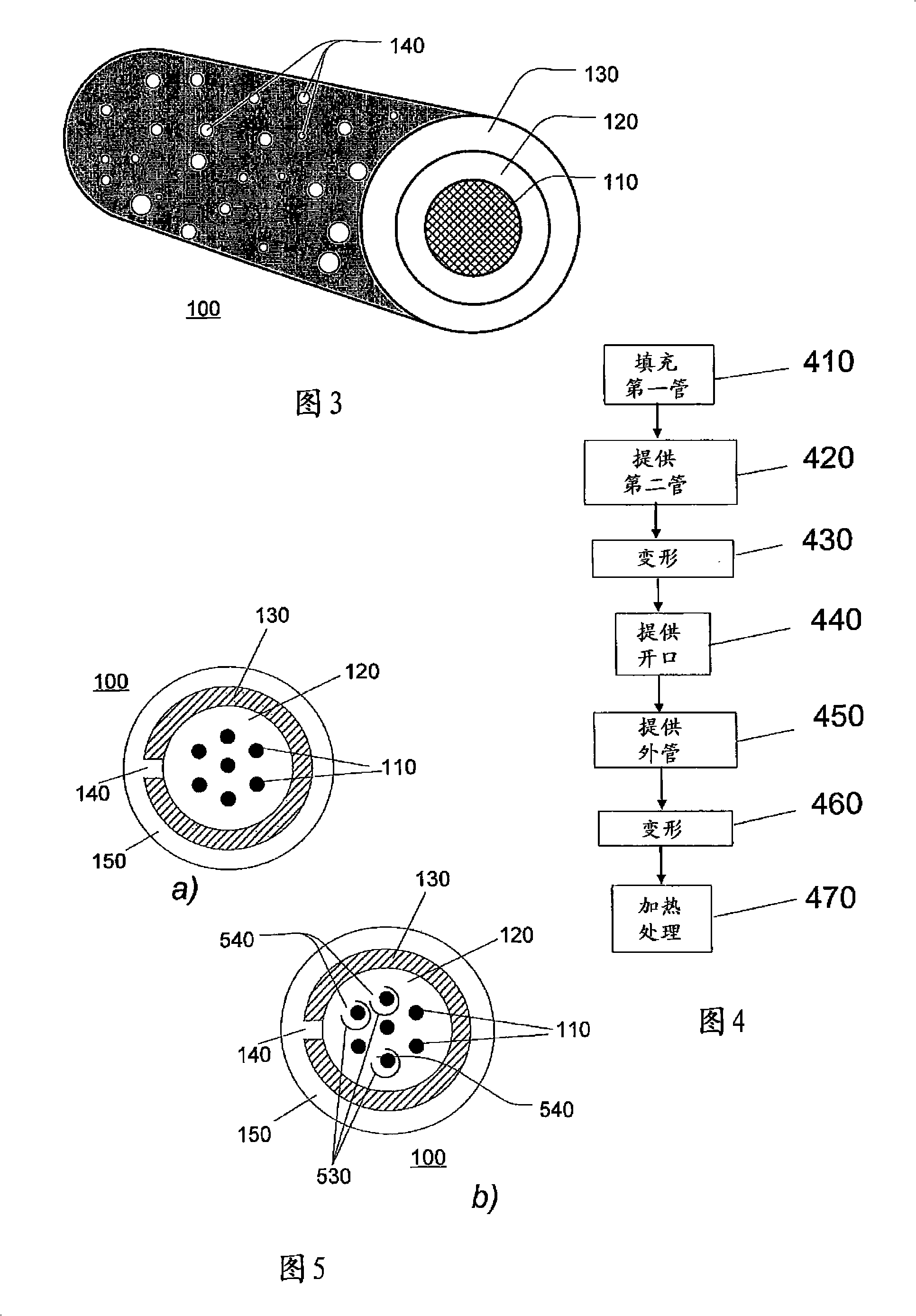

[0046] figure 1 A schematic diagram of a superconducting wire representing an embodiment of a superconducting article. The superconducting wire 100 comprises a core / filament 110 of superconducting material, a first tubular layer 120 of a first material surrounding said superconducting material and a reinforcing tubular layer 130 of a second material surrounding said first material. The reinforcing tubular layer comprises openings 140 in the form of longitudinal channels. A third tubular layer 150 surrounds the second mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com