Art bamboo board shoes and method for producing the same

A production method and bamboo board technology are applied in footwear, manufacturing tools, wood processing utensils and other directions, which can solve the problems of poor fastness of mat slippers, not cool enough to wear, not comfortable enough to wear, etc., and achieve a fresh appearance, strong elasticity, Good ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

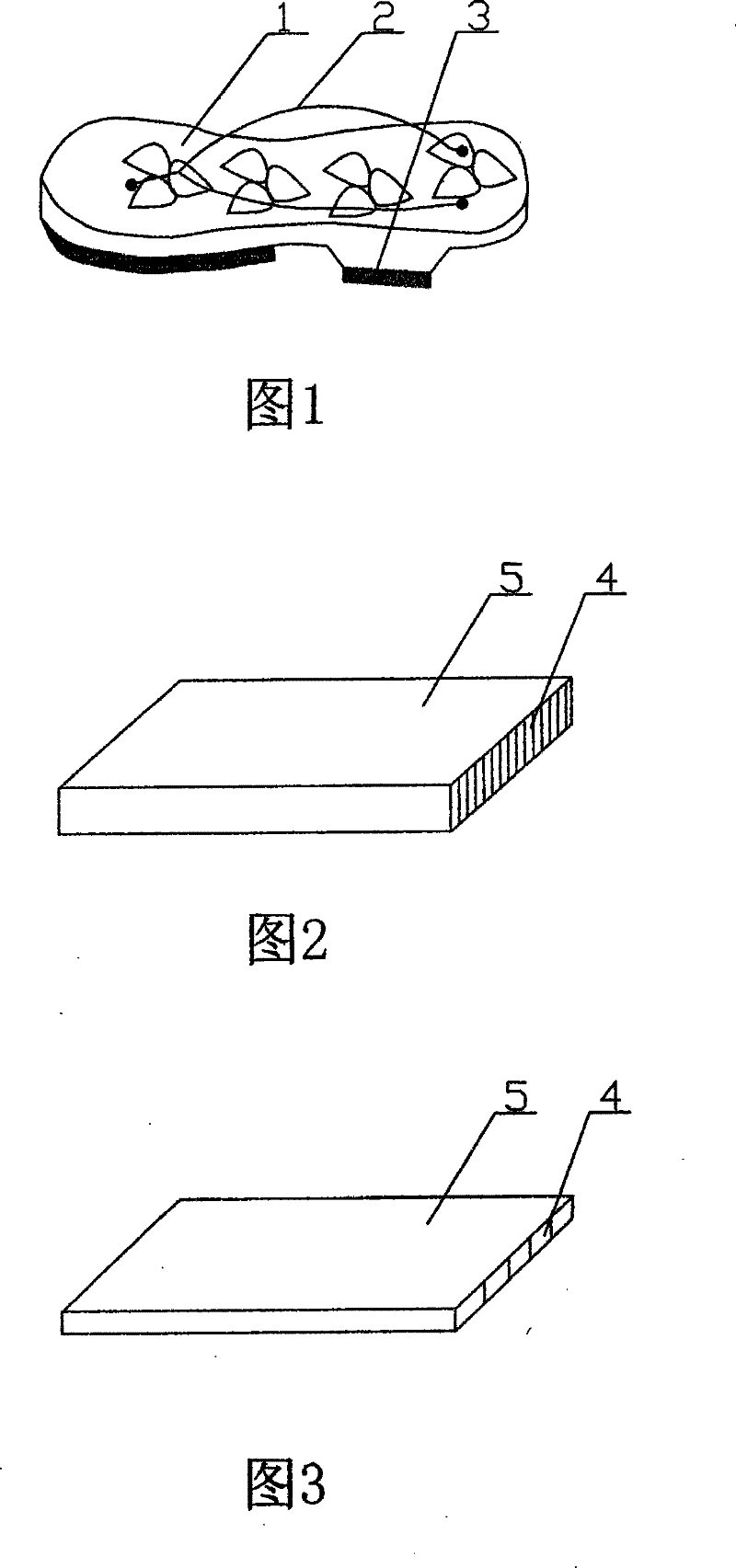

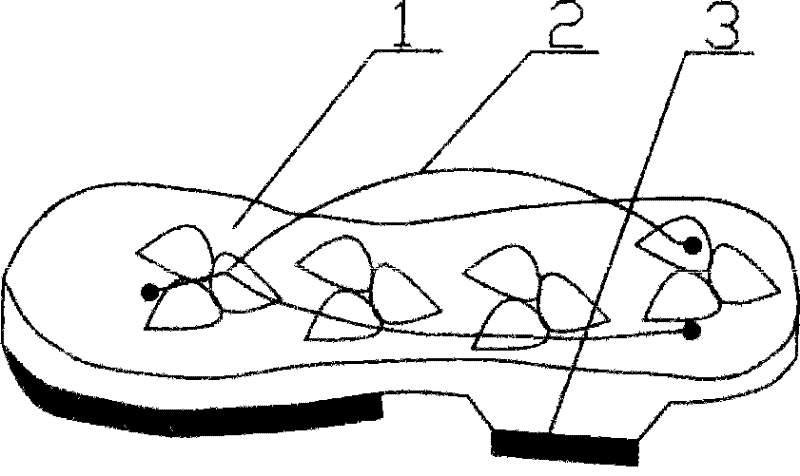

[0030] With reference to accompanying drawing, the embodiment of the present invention is made up of sole 1, shoelace 2 and bottom pad 3, and above-mentioned sole 1 is processed by the bamboo strip bonded board 5 that bamboo strip 4 is made. The preparation method includes the following process steps:

[0031] (1) select bamboo material, bamboo material is mainly Moso bamboo, secondly green bamboo etc.;

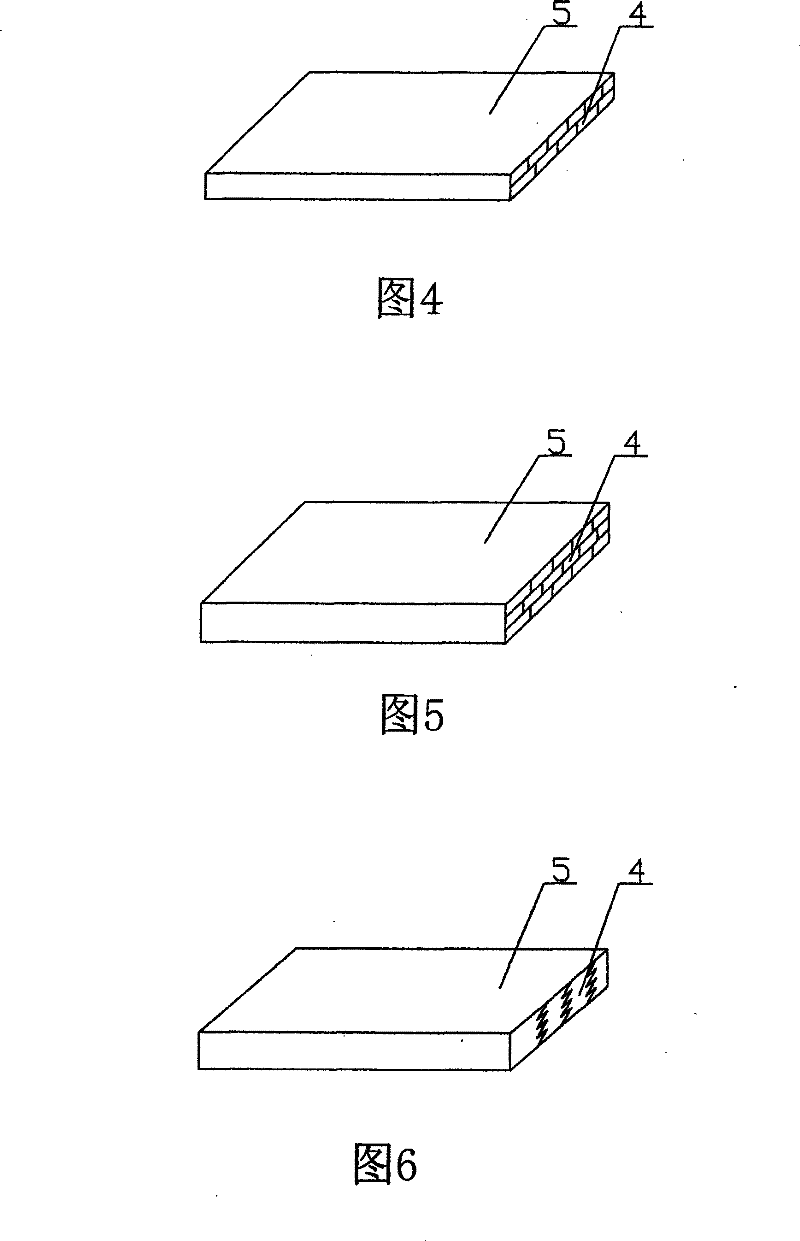

[0032] (2) Bamboo material is processed into bamboo strips 4 with consistent thickness, size, length, and size, and then carries out anti-corrosion treatment;

[0033] (3) The bamboo strips 4 are bonded vertically with high-grade special white latex, urea-formaldehyde resin or polyurethane, etc. (see figure 2 ), Horizontal bonding method (see image 3 ), two-layer or three-layer splicing and bonding method (see Figure 4 , Figure 5 ) and other bonding, in order to make the splicing more firm, even the toothed tenon bonding method is used (see Figure 6 ) bonded, after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com