Irradiation type magic buckle and moulding method

A molding method and magic buckle technology, which is applied in fasteners, clothing, applications, etc., can solve the problems of suede being easily damaged and weak adhesion, and achieve the effect of reducing the cost of use, strong adhesion, and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

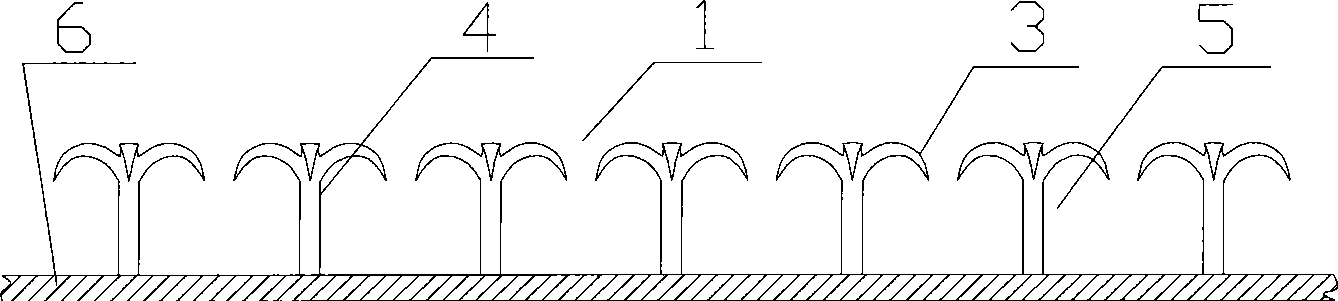

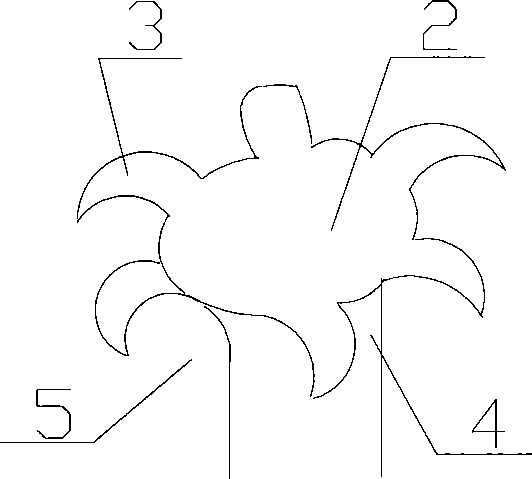

[0012] Embodiment 1: with reference to attached figure 1 with 2 . Radial magic buckle, which includes a magic buckle, the buckle surface 1 of the magic buckle is composed of a plurality of adhesive joints 5 with a neck surface 2 in the middle and radial hooks 3 around; the middle surface of the adhesive joint 5 is 2 is a rectangular surface or a circular surface or an elliptical surface; the radial hooks 3 around the bonding head 5 are angular hooks; the angular hooks in the radial hooks 3 are two or more, such as Two, three, four, five, six, .... The width between the tooth heel and the tooth head of the radial hook 3 varies from 3 to 9 wires, that is to say, if the diameter or width of the tooth hook is 9 wires, the diameter or width of the tooth head is 3 wires, but It is not limited to the limitations of the above data, and can be freely matched as needed.

Embodiment 2

[0013] Embodiment 2: On the basis of Embodiment 1, the forming method of the radial magic button, the unformed magic button is extruded by the core roller, and the core roller makes the surface of the magic button into multiple surfaces 2 in the middle and equidistant around The V-shaped gap of the V-shaped gap and the neck connected with the surface 2, the neck root 4 is connected with the magic button bottom 6, and the V-shaped gaps with multiple V-shaped gaps in the middle and equidistant around the surface are rolled by rollers, and the V The vertical angles on both sides of the glyph gap are ground into angular tooth hooks 3 and a plurality of angular tooth hooks 3 and a plurality of angular tooth hooks 3 form a surface 2 to form a bonding joint 5, and finally the radial magic buckle is formed by sorting rollers. The surface of the radial magic buckle is covered with bonding joints 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com