Wet-type flue gas treating reactor by pulse corona

A technology of pulsed corona and reactor, applied in the direction of external electrostatic separator, air quality improvement, chemical instruments and methods, etc., can solve the problem of uneconomical flue gas treatment, and achieve the reduction of complexity, investment and operation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

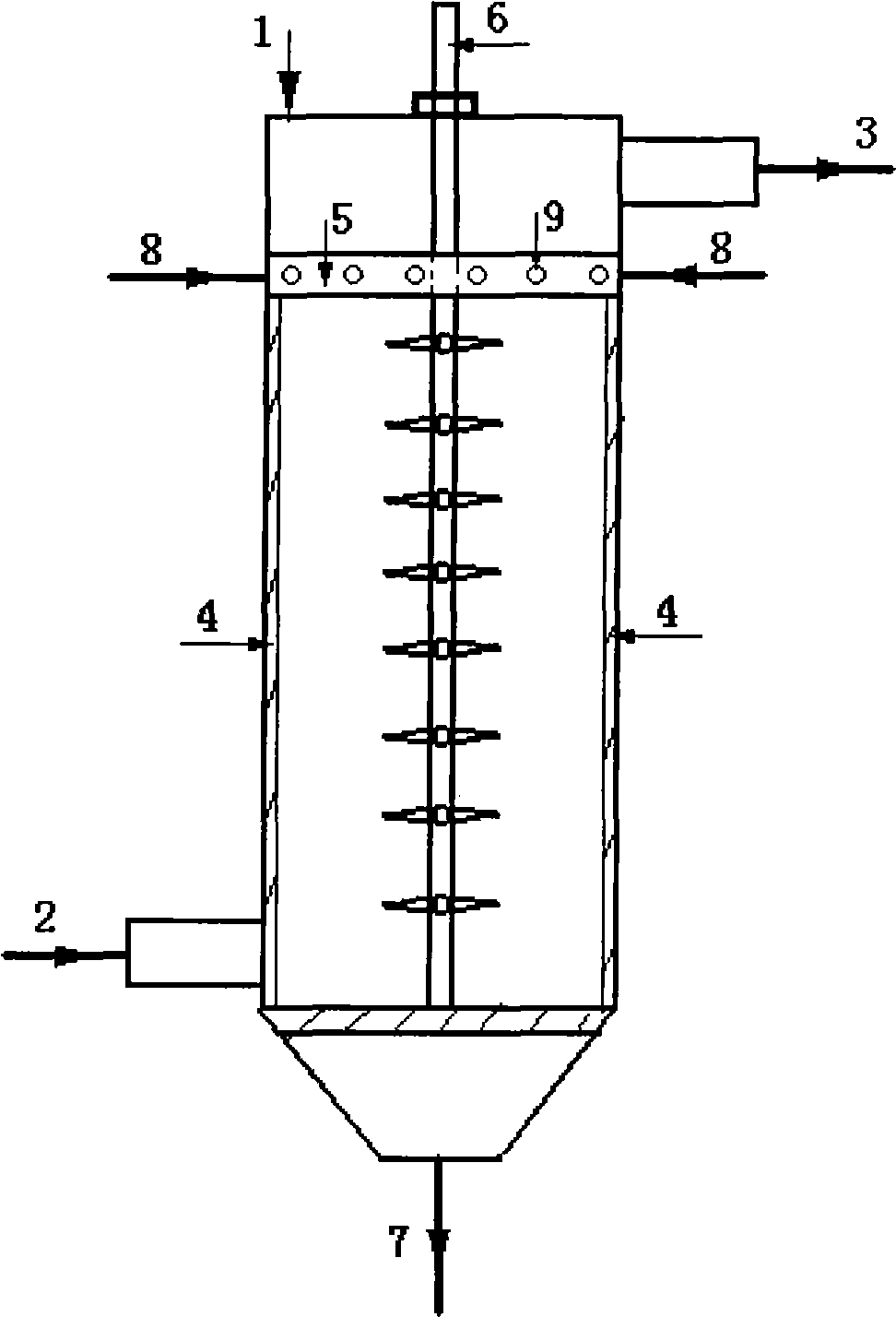

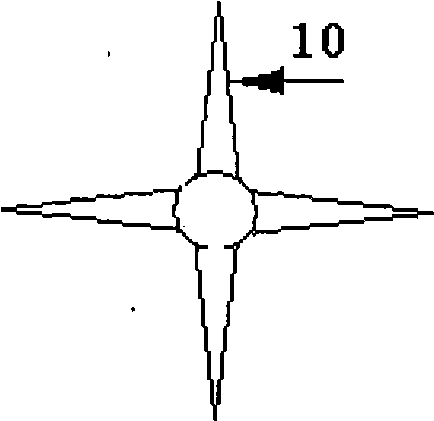

[0018] like figure 1 The wet pulse corona flue gas treatment reactor shown includes a cylindrical shell 1 with a cross-sectional diameter of 100mm; the lower end of the shell 1 is provided with an air inlet 2, and the upper end is provided with an air outlet 3; The flowing water pole plate 4 is arranged close to it, the sprinkler 5 is arranged on the top of the flowing water pole plate 4, and the water outlet 7 is arranged at the bottom of the housing 1. The absorbent enters from the water sprinkler water inlet 8, and then sprays it flow along the water plate 4 from top to bottom, and finally gather at the water outlet 7 and flow into the discharge pool; the center of the shell 1 is provided with a needle-shaped corona wire 6, and the corona wire 6 and the water plate 4 together constitute The two poles of the corona discharge, the flowing water plate 4 is connected to the positive pulse high voltage, and the needle corona wire 6 is connected to the negative pulse high voltage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com