Digital injection pressure device of pressure gel-forming machine

A pressurizing device and pressure gel technology, applied in the field of injection pressurizing devices, can solve the problems of inability to heat materials, control flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

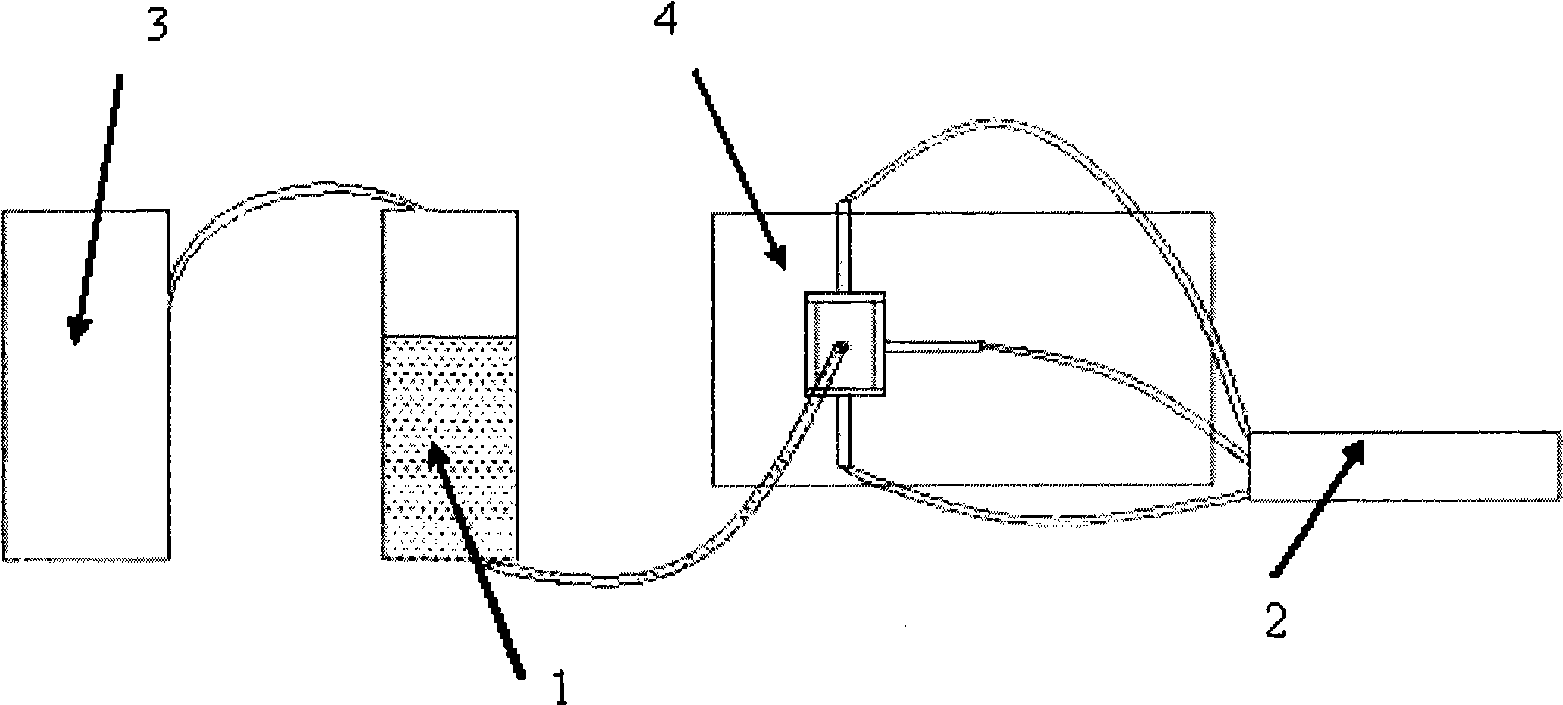

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0015] Depend on Figure 4 It can be seen that the present invention includes: a feed port 10 connected to the material tank, a discharge port 11 connected to the material in the frame; a circulating heating oil pipe 12 is also included between the feed port 10 and the discharge port 11 , and a piston 13 that is arranged on the feed port 10 and the discharge port 11 and can control the discharge port; a control valve 14 is also respectively arranged in the feed port 10 and the discharge port 11;

[0016] Described control valve 14 is a pneumatic ball valve;

[0017] The control valve 14 and the piston 13 are respectively connected with a digital display mechanism (not shown in the figure).

[0018] The invention is connected with the material tank and the machine frame, plays a transitional heating and pressurizing function, and digitally disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com