Lubricant composition for bio-diesel fuel engine applications

A technology of lubricating oil composition and biodiesel, which is applied in the direction of lubricating composition, petroleum industry, additives, etc., and can solve the problems of increased use of biodiesel fuel and increased treatment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

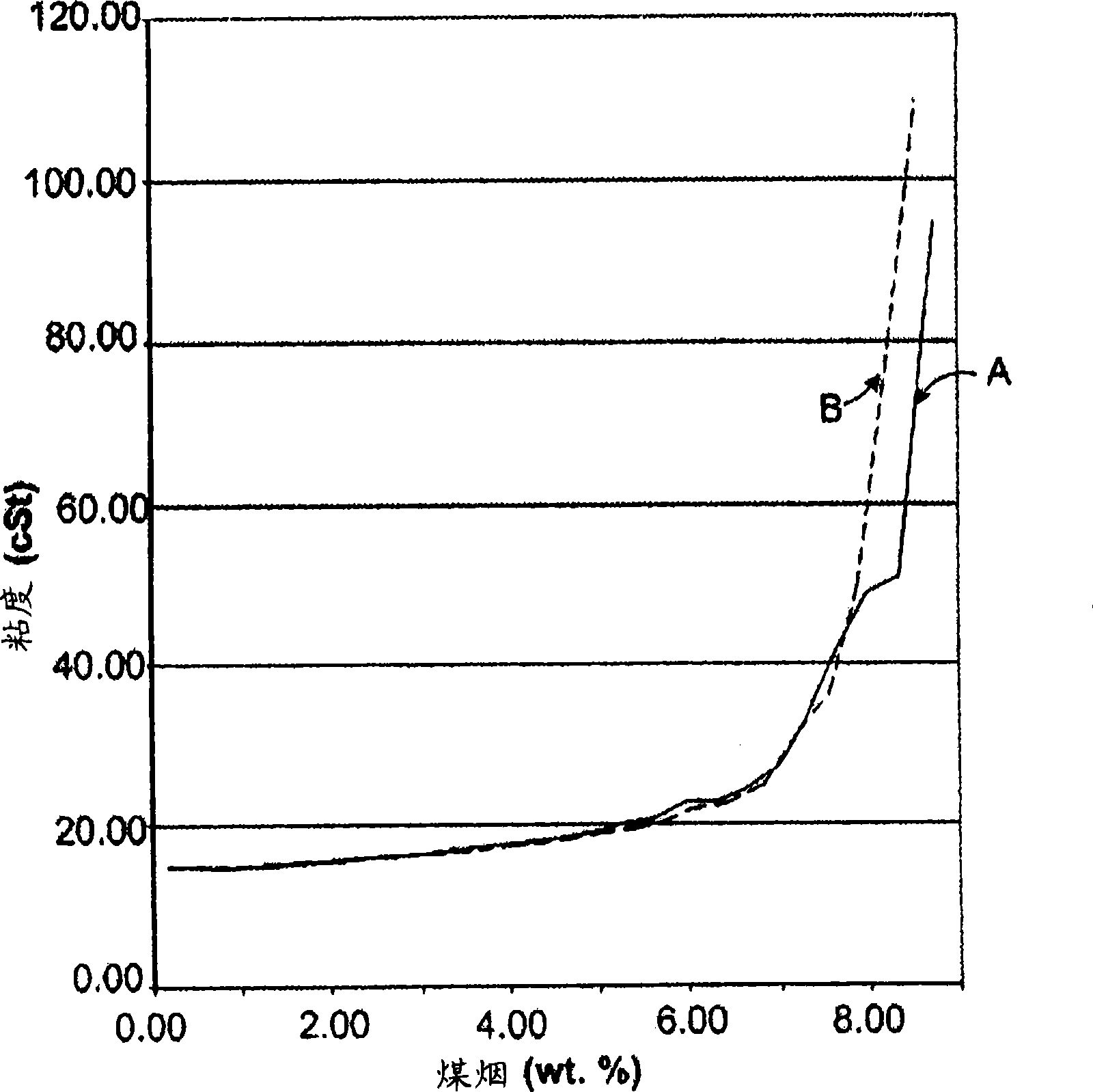

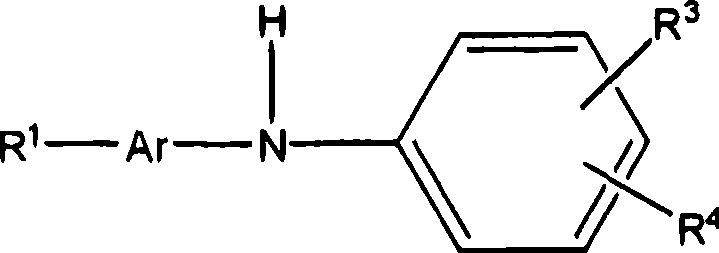

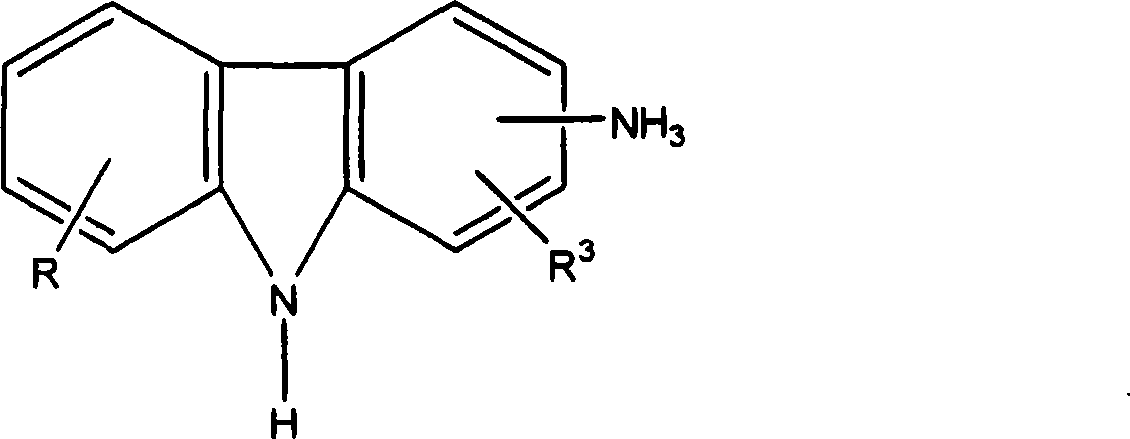

[0010] As described in more detail below, lubricating oils for diesel engines operating on fuels containing biodiesel components can be synergistically improved by the addition of specific highly grafted multifunctional olefin copolymers. More specifically, a highly grafted olefin copolymer as a dispersant / viscosity index improver in a lubricating oil containing a conventional dispersant / inhibitor (DI) package was significantly improved for use in some Engines that run on biodiesel fuel. As described more fully herein, such lubricating oil compositions may be particularly useful for lubricating internal combustion engines (eg, heavy-duty diesel engines and light-duty diesel engines, including diesel engines equipped with exhaust gas recirculator (EGR) systems). Lubricant compositions containing highly grafted multifunctional olefin copolymers may have improved soot dispersion properties (deagglomeration), deposit control and boundary film formation properties, as well as impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com