A low-ash, long-life, environmentally friendly city gas engine oil

A gas engine, long-life technology, applied in the field of environmentally friendly urban gas engine oil, low ash, long life, can solve the problems of shortened service life of lubricating oil, spark plug pollution, valve seat collapse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

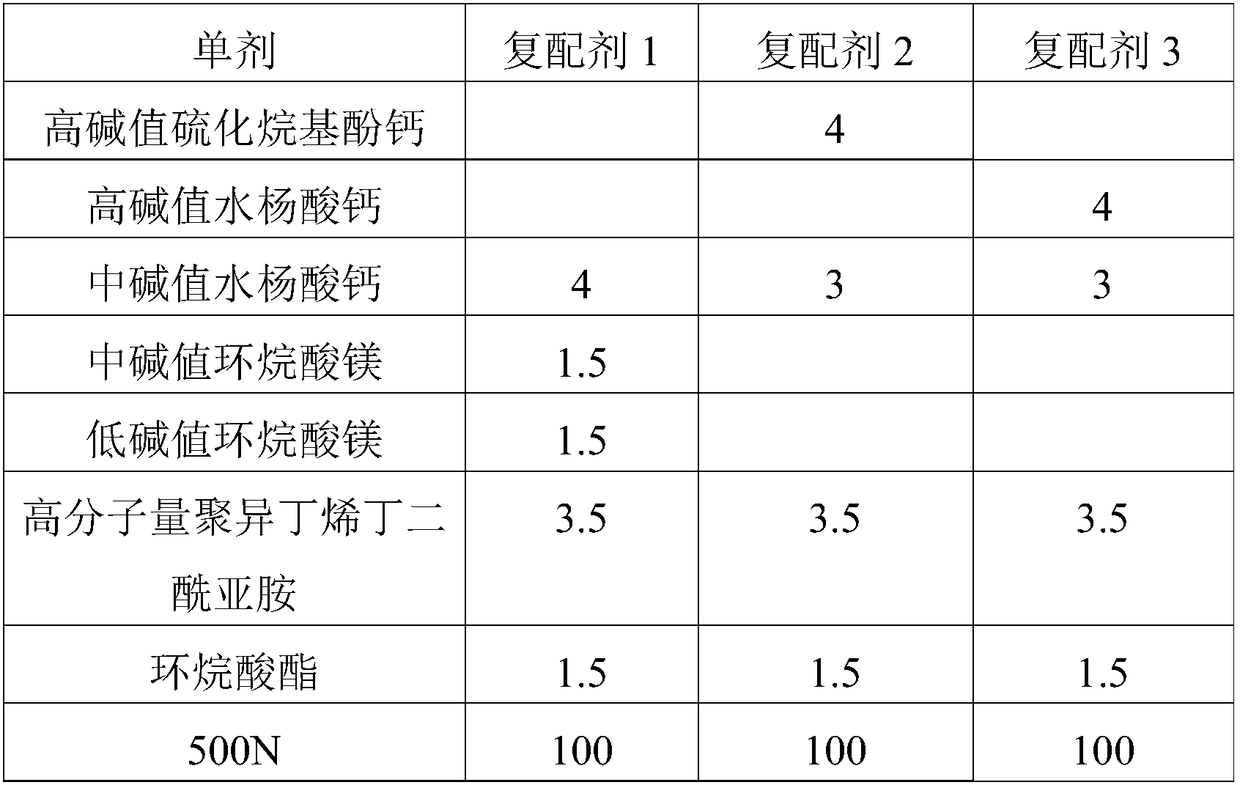

[0070] According to the proportioning of raw materials in Table 12, and prepare low ash content, long life, environmental protection city gas engine oil by following method.

[0071] Mix the base oil evenly in proportion. Add 50% of the uniformly mixed base oil into the kettle, stir and heat up to 50°C, add polymethacrylate (12C), and stir for 0.5h; dilute polymethacrylate (10C) with 10% mixed base oil After that, add it into the kettle, stir and heat up to 50°C, and stir for 1.5 hours; mix calcium salicylate with medium alkali value, magnesium naphthenate with medium alkali value, magnesium naphthenate with low alkali value, high molecular weight polyisobutylene succinimide, Naphthenate, diluted with 10% mixed base oil and added to the kettle, heated to 65°C, fully mixed by stirring and static mixer, time 1.5h; added phenolic ester type ashless antioxidant, 4,4 '-Dioctyl diphenylamine and thiadiazole were fully mixed by stirring and static mixer for 0.5h; the above processes...

Embodiment 4

[0075] Low ash content, long life, environmental protection city gas engine oil raw materials (parts by weight): 3.6 parts of calcium alkylbenzene sulfonate, 3.6 parts of sulfurized calcium alkylphenate, 4.8 parts of borated polyisobutylene succinimide, polymethyl 7 parts of acrylate, 0.8 part of phenolic ester type ashless antioxidant, 0.4 part of 4,4'-dioctyldiphenylamine; 0.01 part of N,N-di(dodecyl)alkyl dithiocarbamate molybdenum; 0.003 parts of methyl silicone oil; 0.2 parts of thiadiazole; 20 parts of 150N base oil, 25 parts of 500N base oil, 25 parts of polyalphaolefin, 25 parts of trinonyl trimellitate, 5 parts of 150BS bright oil.

[0076] The phenolic ester type ashless antioxidant consists of 50wt% thiodiethylene bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] and 50wt% hexanediol bis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] obtained by stirring and mixing uniformly.

[0077] Low ash content, long life, environmental protection city gas engine oil ...

Embodiment 5

[0079] Prepare low ash content, long life, environment-friendly city gas engine oil by the method for embodiment 4, difference only is: described phenolic ester type ashless antioxidant is only thiodiethylene bis[3-(3,5 -di-tert-butyl-4-hydroxyphenyl)propionate]. Obtain the low ash content of embodiment 5, long life, environment-friendly city gas engine oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com