Shock insulation support saddle with transversal elastic-plastic anti-fall girder apparatus

An anti-drop beam, elastic-plastic technology, used in bridges, bridge parts, bridge construction and other directions, to achieve the effect of simple on-site installation, reducing seismic response, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

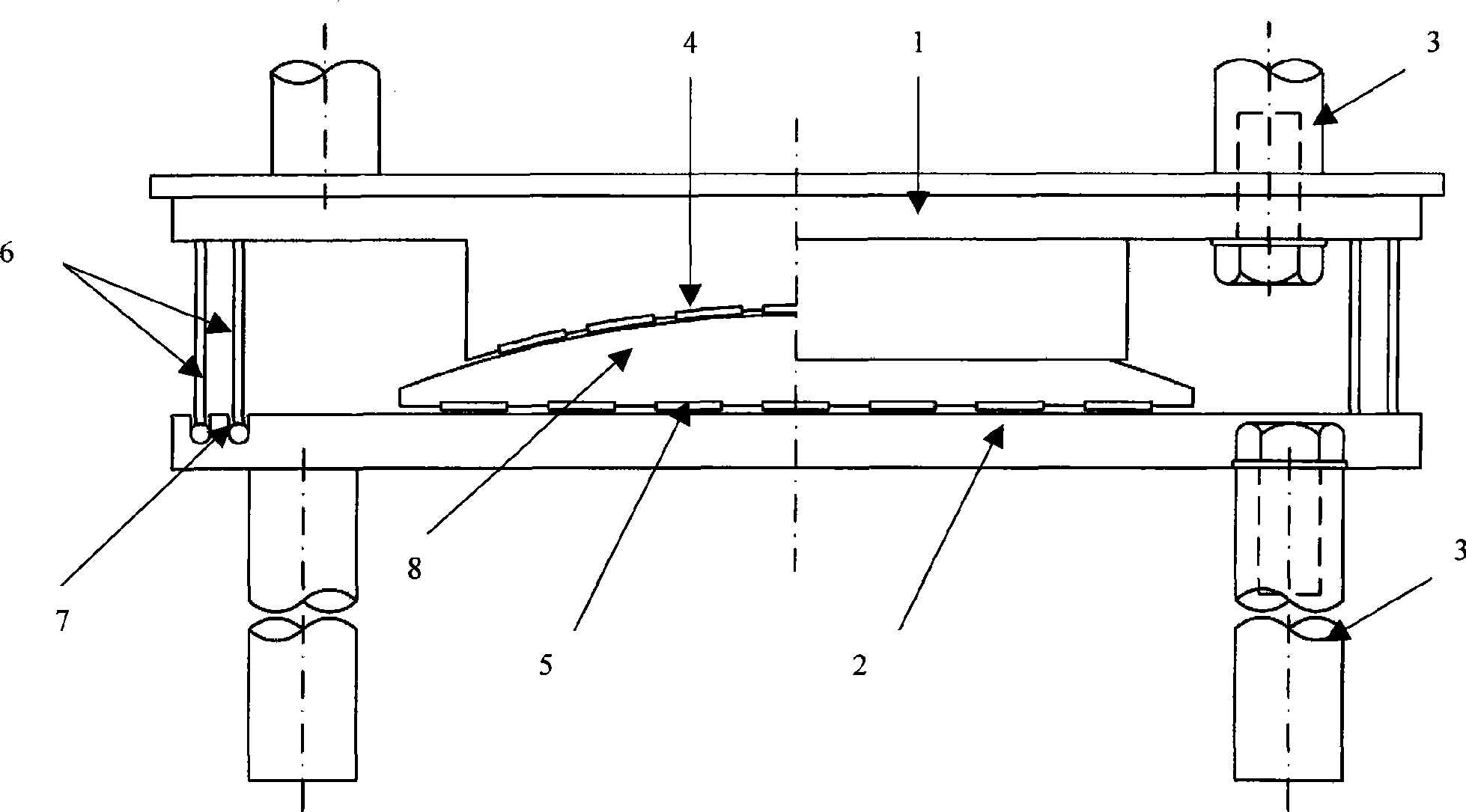

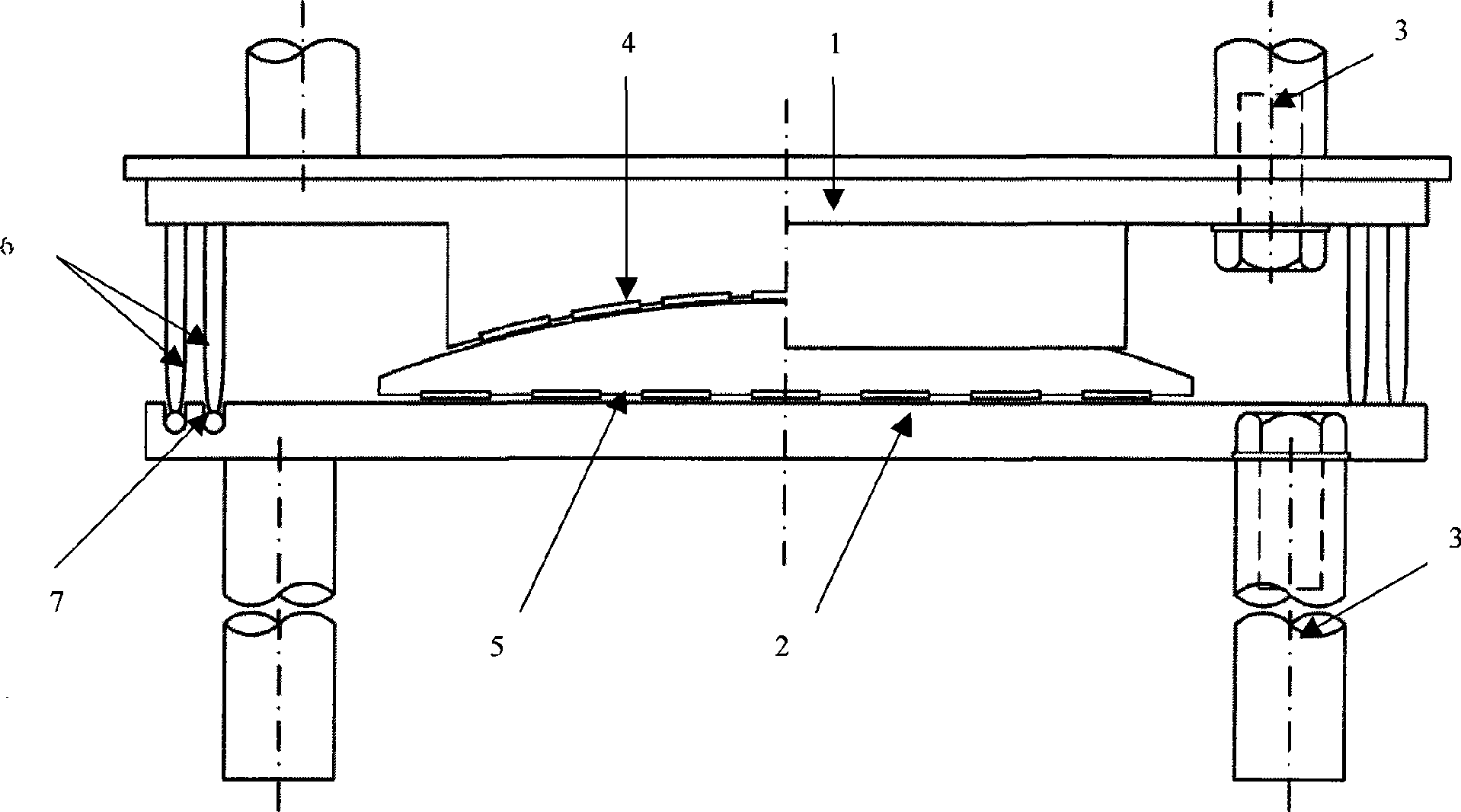

[0032] A shock-absorbing and isolating support with a transverse elastic-plastic anti-drop beam device, the support adopts QZ2000SX two-way movable spherical support. The displacement along the bridge is ±100mm, and the displacement along the bridge is ±150mm.

[0033] The transverse elastic-plastic anti-drop beam device is composed of 12 isosceles triangle cantilever plates of equal thickness, the plate thickness is 30mm, the plate height is 0.3m, and the plate width at the root of the cantilever beam is 0.15m. Made of low-strength, high-ductility metal materials, material σ y =200MPa, E=200GPa, ε max = 0.05. Design maximum displacement = 150mm. (see Figure 1 ~ Figure 2 ).

Embodiment 2

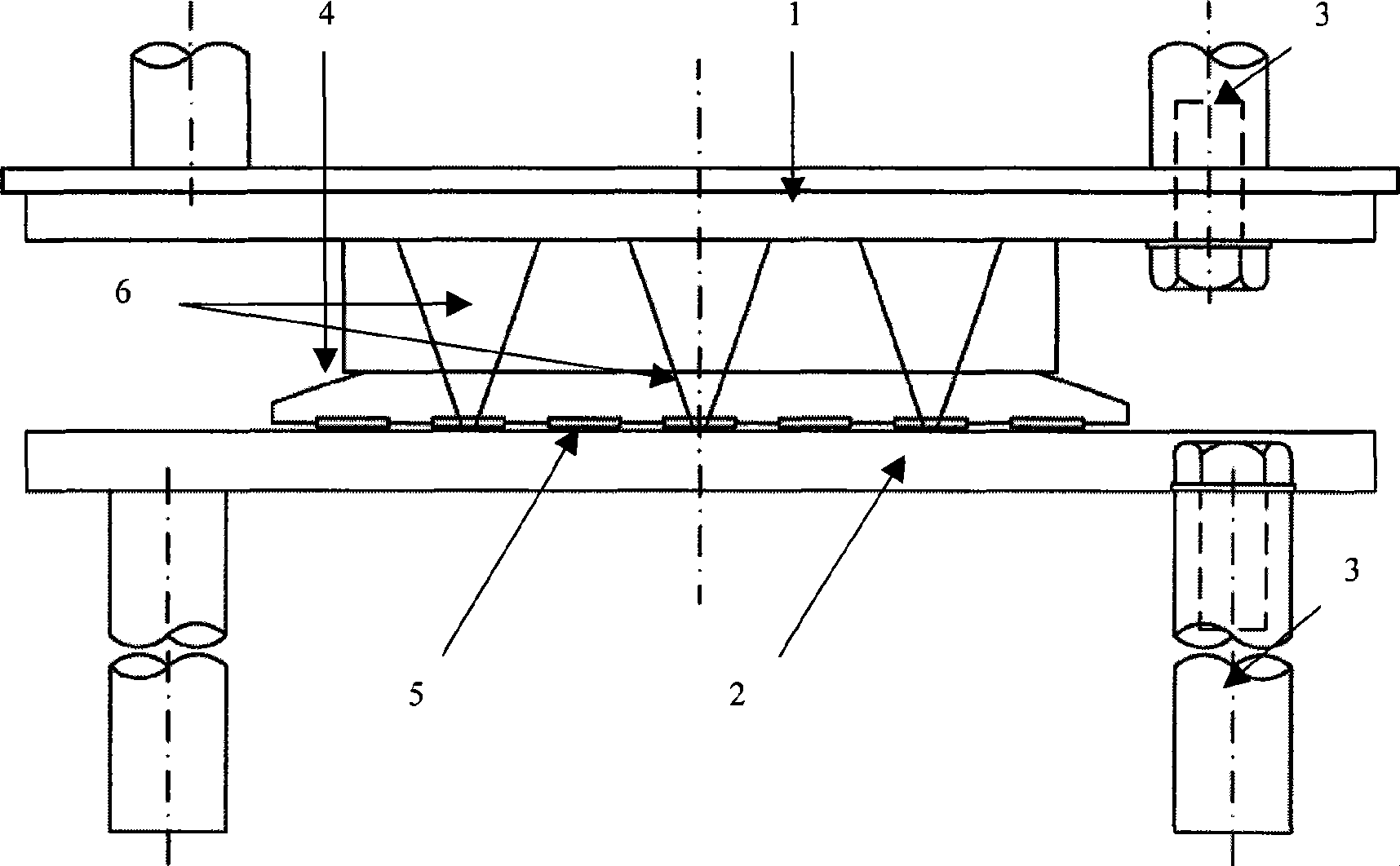

[0035] A shock-absorbing and isolating support with a transverse elastic-plastic anti-drop beam device, the support adopts a QZ2000SX two-way movable spherical support. The displacement along the bridge is ±100mm, and the displacement along the bridge is ±150mm.

[0036] The transverse elastic-plastic anti-fall beam device is composed of 8 cantilever columns whose circular section diameter is proportional to 1 / 3 of the height, the column height is 0.3m, and the circular section radius at the bottom of the column is 0.027m. Made of high-strength metal materials, material [σ] = 1000MPa, E = 200GPa, ε max = 0.05. Design maximum displacement = 150mm. (see Figure 3 ~ Figure 4 ).

[0037] As a modification of the embodiment of the present invention, the support that cooperates with the transverse elastic-plastic anti-fall beam device can also adopt other types and indexes besides the spherical support.

[0038] As another modification of the embodiment of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com