Method and supporting construction for enlarging basement top-down method earth excavation space

A technology for earthwork excavation and support structures, which is applied to underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as slow construction progress, and achieve the effects of speeding up excavation progress and significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

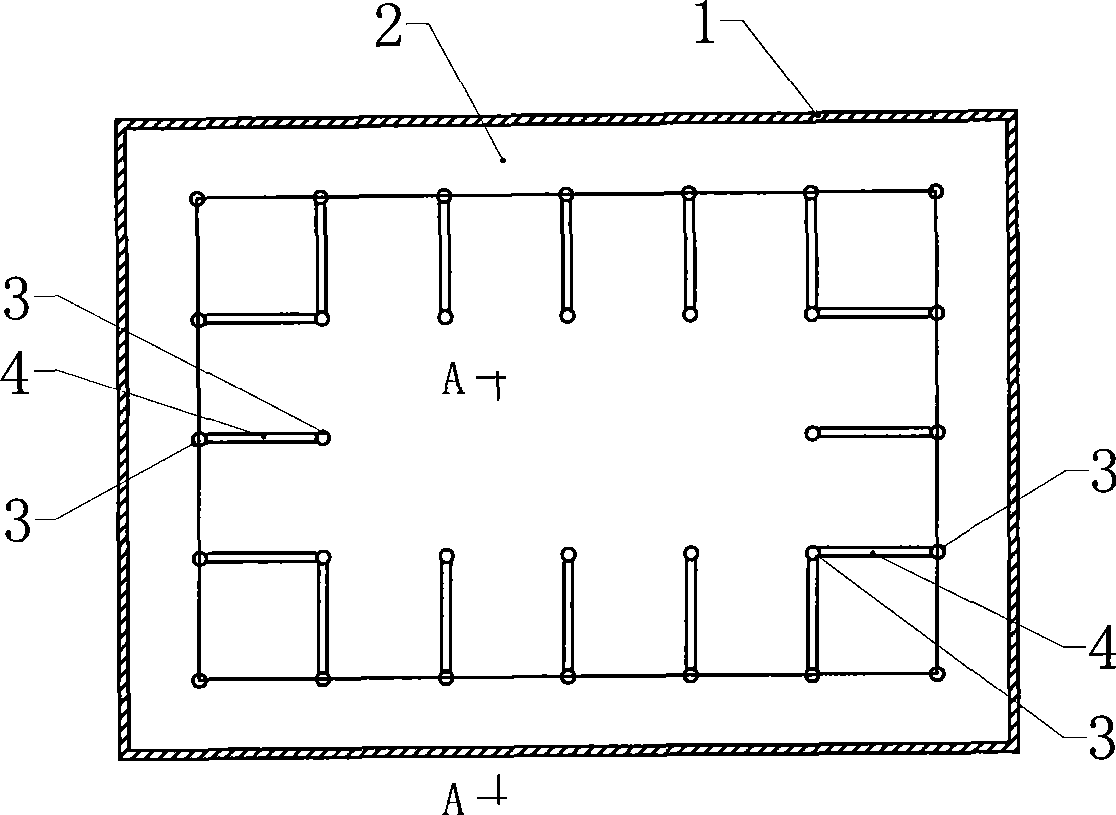

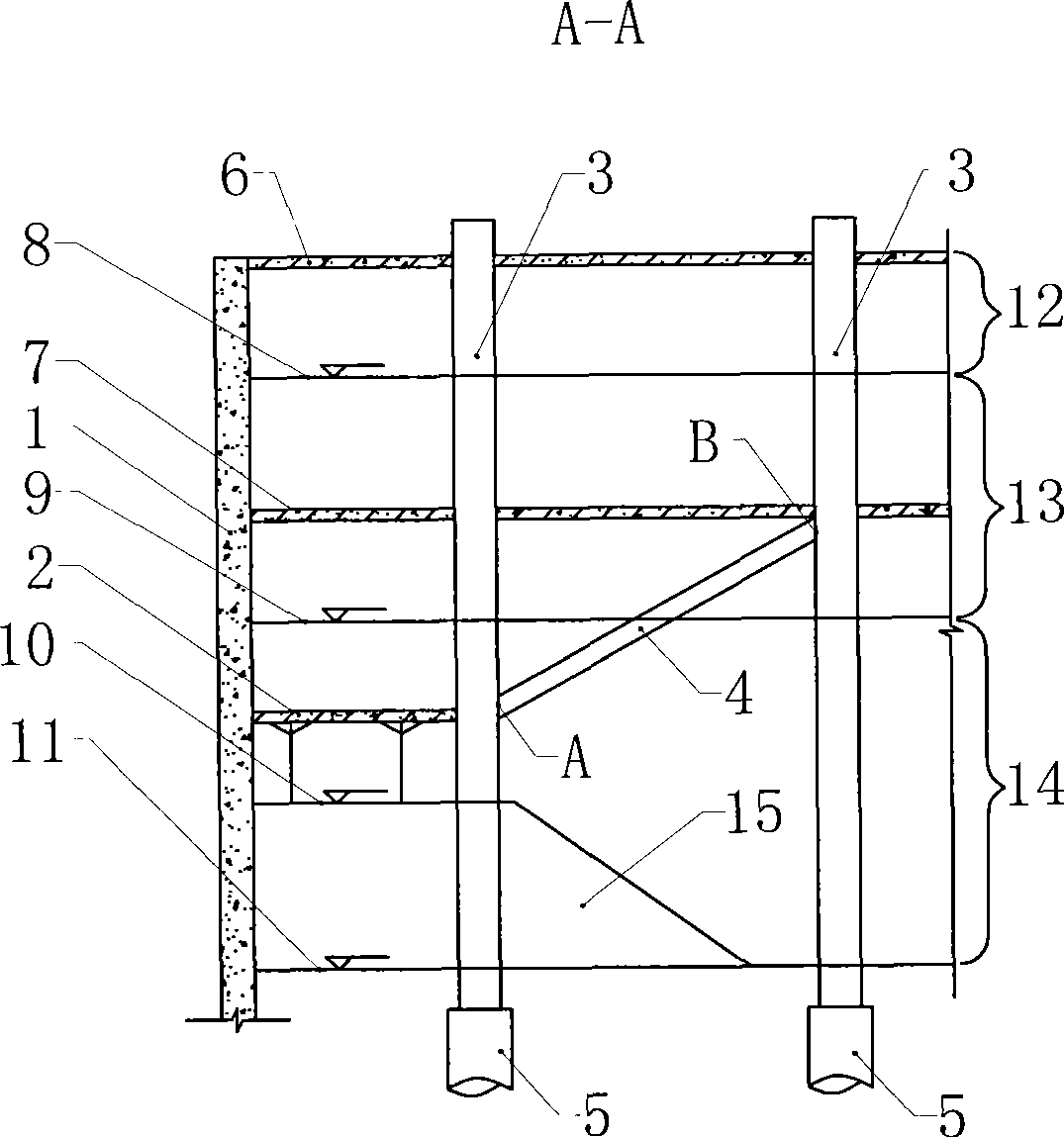

[0020] Such as figure 1 and figure 2 As shown, the present embodiment is applied to a three-story basement constructed by the upside-down method. Before implementing the present invention, the reverse method construction order of building basement is:

[0021] 1. First construct the underground diaphragm wall 1 along the surrounding of the basement of the building, and at the same time arrange the artificial excavation pile 5 and the middle supporting steel pipe column 3 inside the building at the center of the basement column of the building and the intersection of the vertical and horizontal frame beams and shear walls. ;

[0022] 2. Excavate earthwork 12 to -2.700m elevation 8, and construct ±0.000-story floor structure 6;

[0023] 3. Excavate the earthwork 13 to position 9 2.40m below the floor of the negative floor, and construct the floor structure 7 of the negative floor.

[0024] Since the existing top-down construction method uses the constructed floor structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com