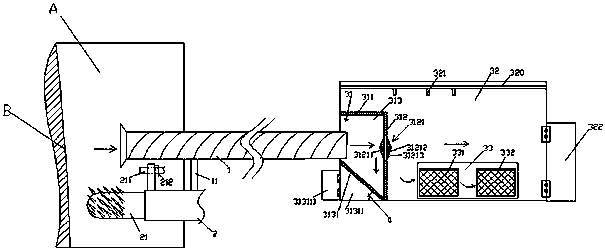

Ventilating and dust-removing construction method for excavating small-section tunnel with single-cantilever heading machine

A technology of a cantilever roadheader and a construction method, applied in separation methods, chemical instruments and methods, dust-proof and other directions, can solve the problems of smoke and dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] Electrical operation steps: Move the power switch handle on the right side of the electrical control box upwards to the "on" position, and the front and rear lights are on at the same time. Check the display screen, voltmeter and the surroundings of the machine. If there is no abnormality, you can start the machine in the following order.

[0039] Turn the "Signal, Alarm" switch clockwise to send a power-on signal. And observe the work site to confirm that no mechanical and personal accidents can occur before starting the machine.

[0040] Turn the oil pump start switch clockwise, and the oil pump can start running. Rotate the oil pump motor stop switch counterclockwise, and the running oil pump motor will stop. (Attention should be paid to the running direction of the oil pump motor during the test run, if it is reversed, the wiring should be reconnected).

[0041] Turn the "signal, alarm" switch counterclockwise to send the "alarm" signal to start the cutting motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com