Demountable three-dimensional beam-and-column construction method

A beam-column structure and three-dimensional technology, which is applied in the field of construction and building composite structures, can solve problems that do not meet energy conservation and environmental protection, and achieve the effect of light weight, light weight and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

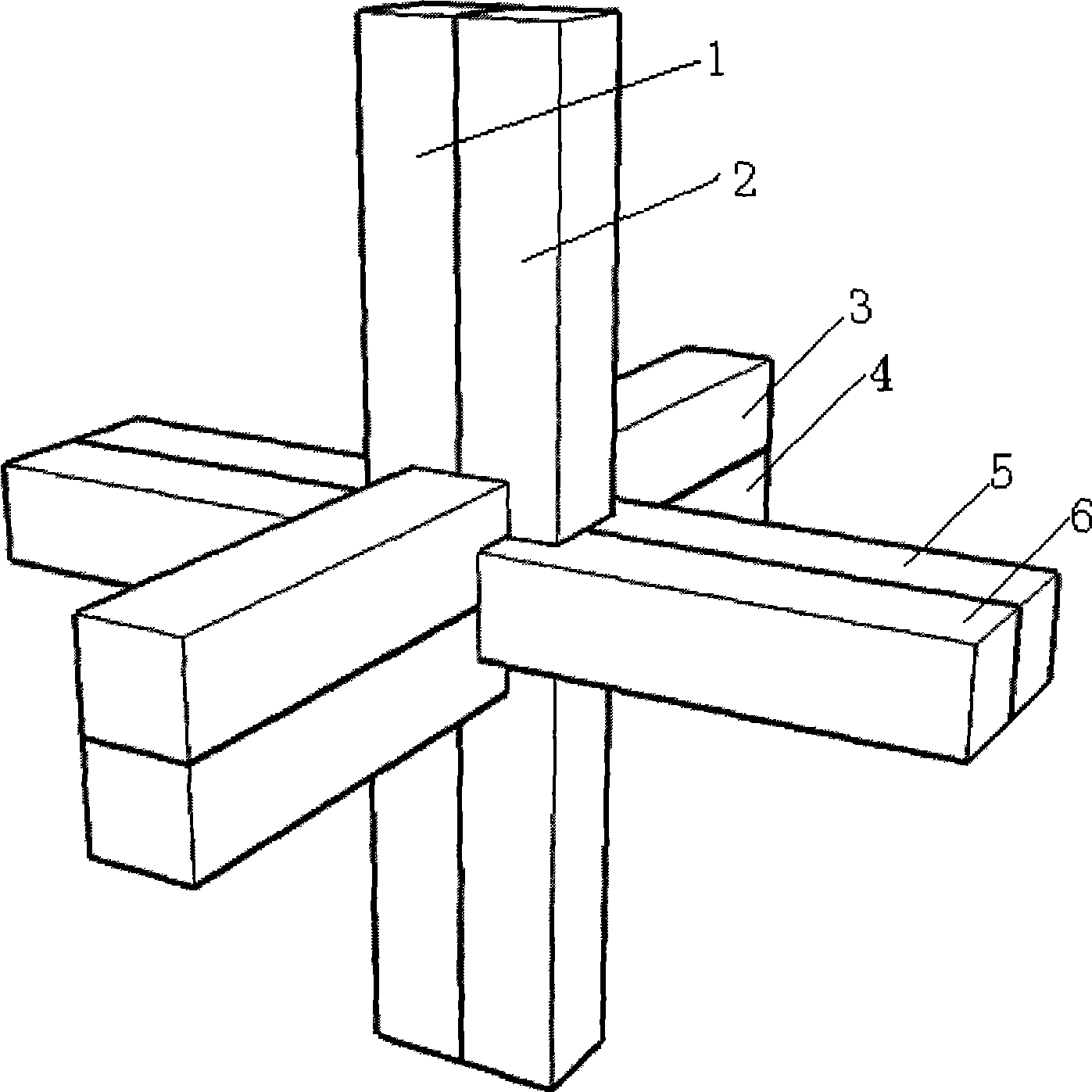

[0028] Embodiment 1: A method for building a work platform with a three-dimensional beam-column structure coded by four digits of cutouts.

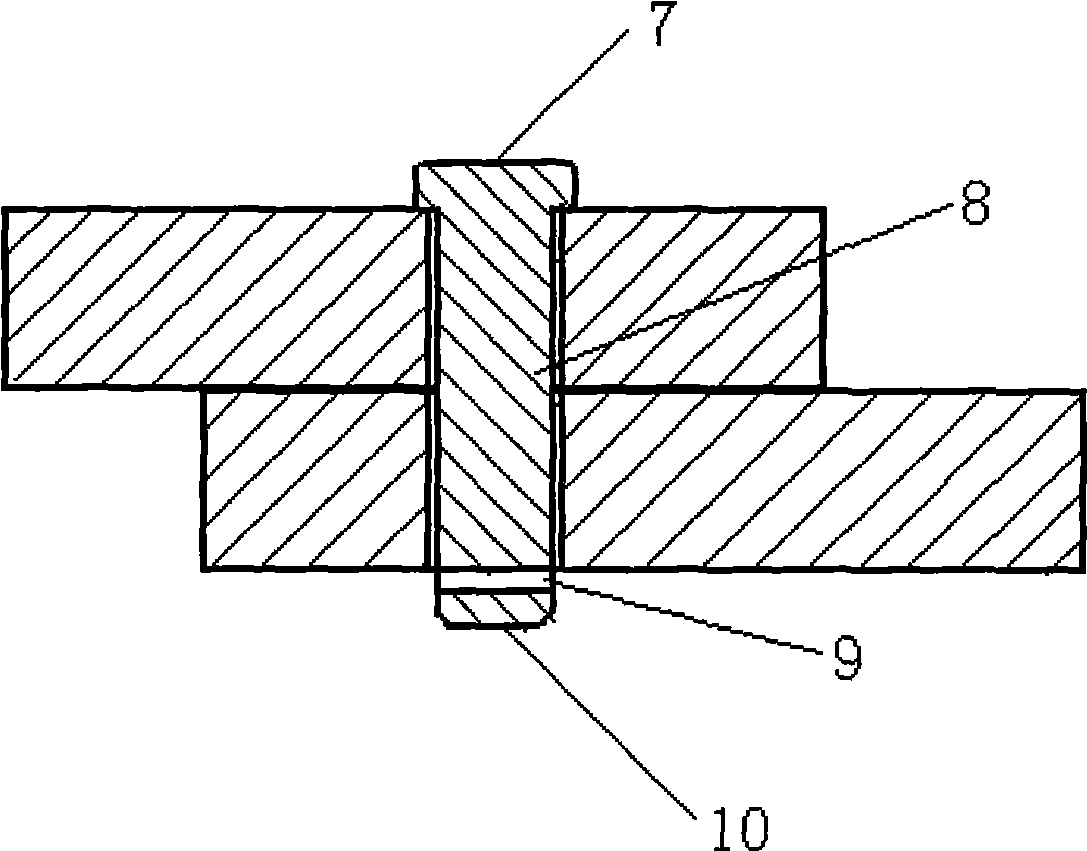

[0029] The connection points of the three-dimensional beam-column structure are as follows: figure 1 As shown, it is composed of six materials: main column (1), auxiliary column (2), main warp beam (3), auxiliary warp beam (4), main weft beam (5), and auxiliary weft beam (6). The weighing column perpendicular to the ground has a main column (1) and an auxiliary column (2). The beams parallel to the ground are called warp beams and weft beams. It is characterized in that the columns, the warp beams and the weft beams intersect each other at 90 degrees and the joint positions, and each has auxiliary columns (2), auxiliary warp beams (4) and auxiliary weft beams (6).

[0030] The auxiliary column (2) is also called the lining column, which is parallel to the main column (1). The auxiliary warp beam (4) is also called the warp lining beam, ...

Embodiment 2

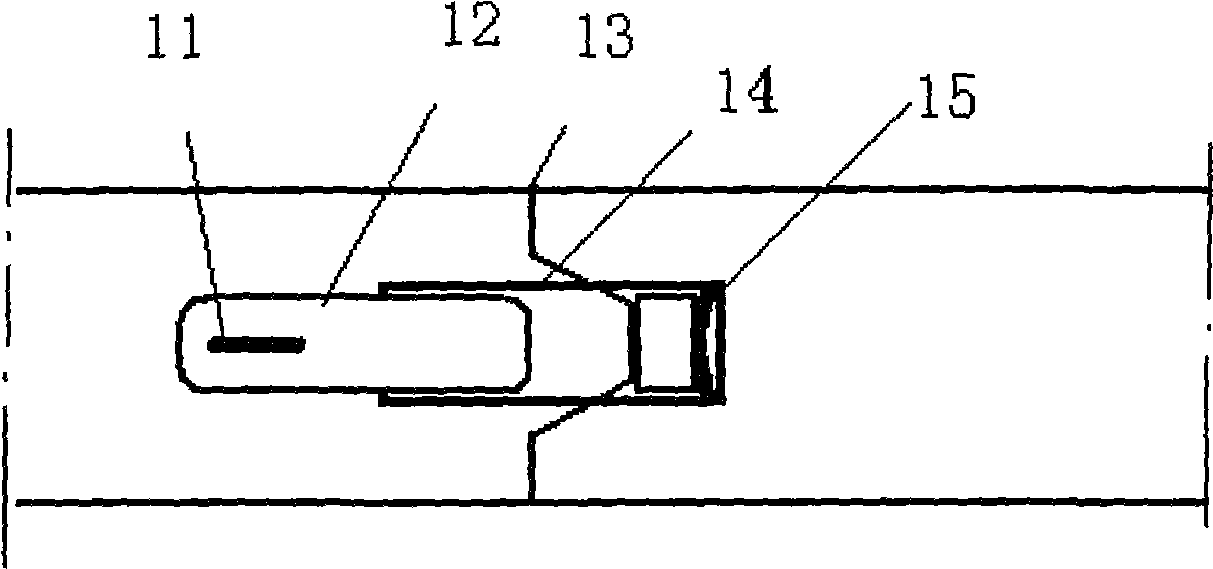

[0035] Example 2: A three-dimensional beam column made of aluminum-titanium alloy adopts a hollow structure, and its cross-section is as follows Figure 5shown. The section (16) of the structural beam column with the four-digit notch code adopts a cross frame to support the square frame edge, and the section (18) of the reinforced structural beam column adopts a double cross frame to support the square frame edge. In order to make a good combination between the column beam and the partition (or wall panel), slots with the thickness of the partition are opened on the sides of the thin-walled hollow column beams, and the cross-section (17) of the beam-column structure with slots on both sides adopts a cross frame The square frame is supported, and the section (19) of the beam-column structure with slits on four sides adopts a well-shaped skeleton to support the square frame.

[0036] The incision codes used are: 1001 / 1221, 0110 / 0122, 1111 / 1111, 0110 / 2210, 1111 / 1221, 0000 / 0000. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com