Wastepaper burning machine

A technology of waste paper and rubber sleeves, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as environmental pollution, inability to deal with waste paper such as sanitary napkins, and toilet blockage, and achieve high incineration efficiency, complete incineration, The effect of using less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

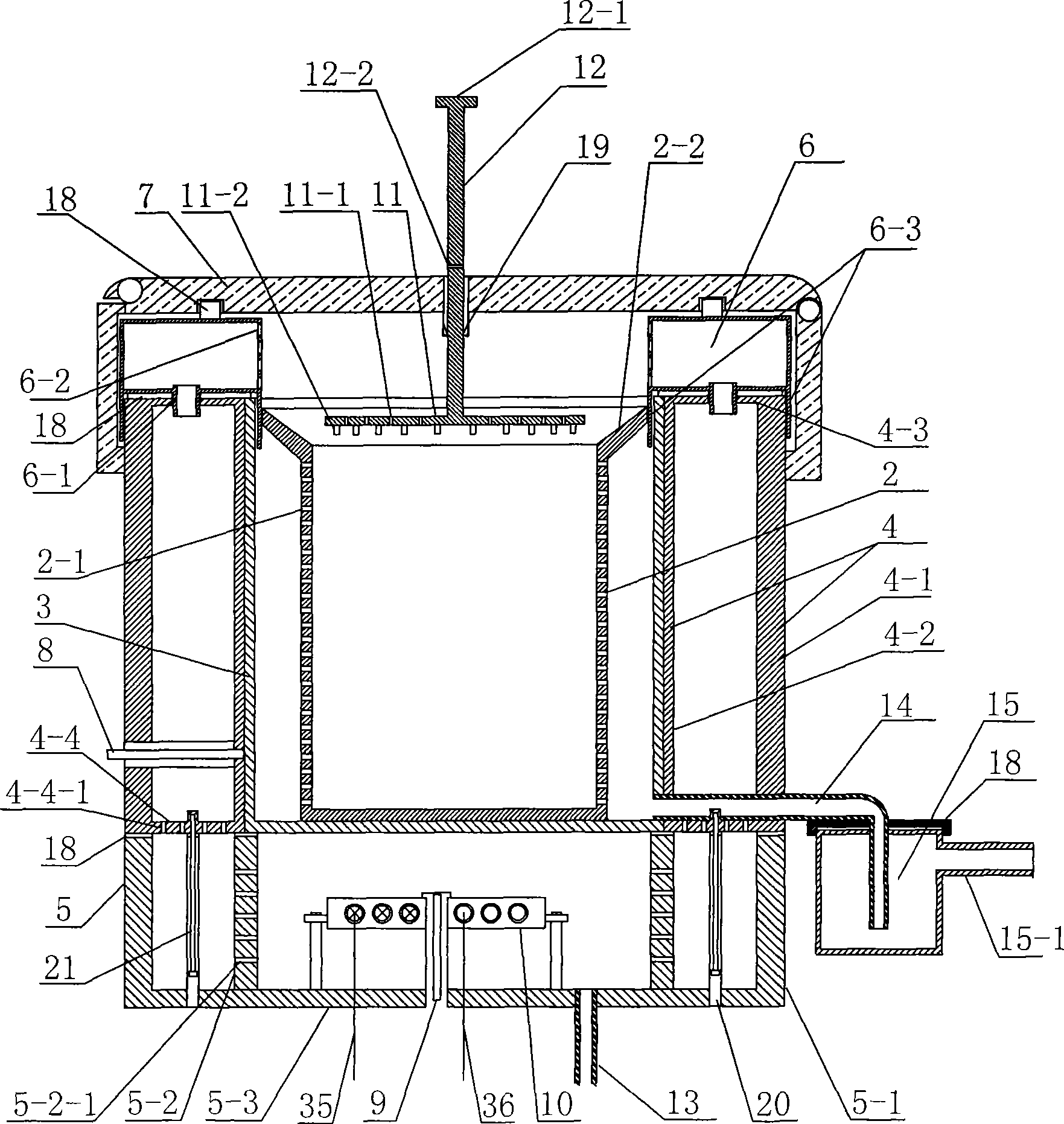

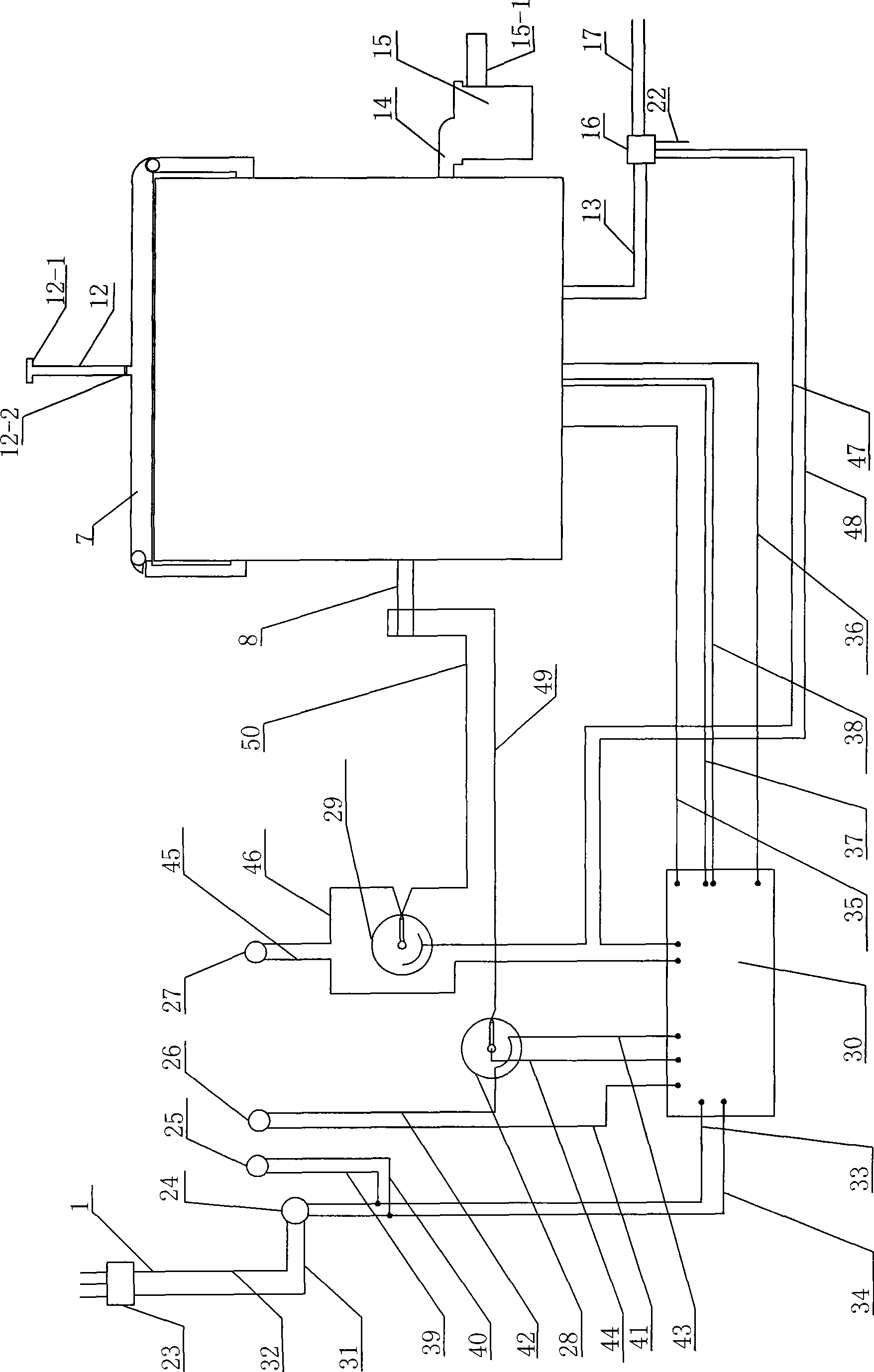

[0009] The present invention is described below in conjunction with accompanying drawing:

[0010] Such as figure 1 , 2 As shown: the present invention includes a power switch 1, a through-hole iron barrel 2, a refractory ceramic barrel 3, an upper rubber sleeve barrel 4, a lower rubber sleeve barrel 5, a stainless steel sleeve barrel 6, a stainless steel cover 7, an electronic high temperature circuit breaker 8, an electronic Water temperature and high temperature circuit breaker 9, coil 10, pressure plate 11, connecting rod 12, water inlet pipe 13, water outlet pipe 14; the rubber sleeve barrel includes upper outer wall 4-1, upper inner wall 4-2, upper annular top plate 4-3 and lower annular The bottom plate 4-4, the lower rubber sleeve barrel includes the lower outer wall 5-1, the lower inner wall 5-2 and the lower plate 5-3; the top between the upper outer wall 4-1 and the upper inner wall 4-2 is provided with an upper annular top plate 4-3 1. The bottom is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com