Controlling method and apparatus for four switch step-up step-down DC-DC converter

A technology of a DC converter and a control method, which is applied in the direction of converting DC power input to DC power output, output power conversion equipment, and conversion equipment without intermediate conversion to AC, which can solve the problem of slow output voltage drop and output voltage failure. Problems such as rapid recovery and no energy transfer can achieve the effect of improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

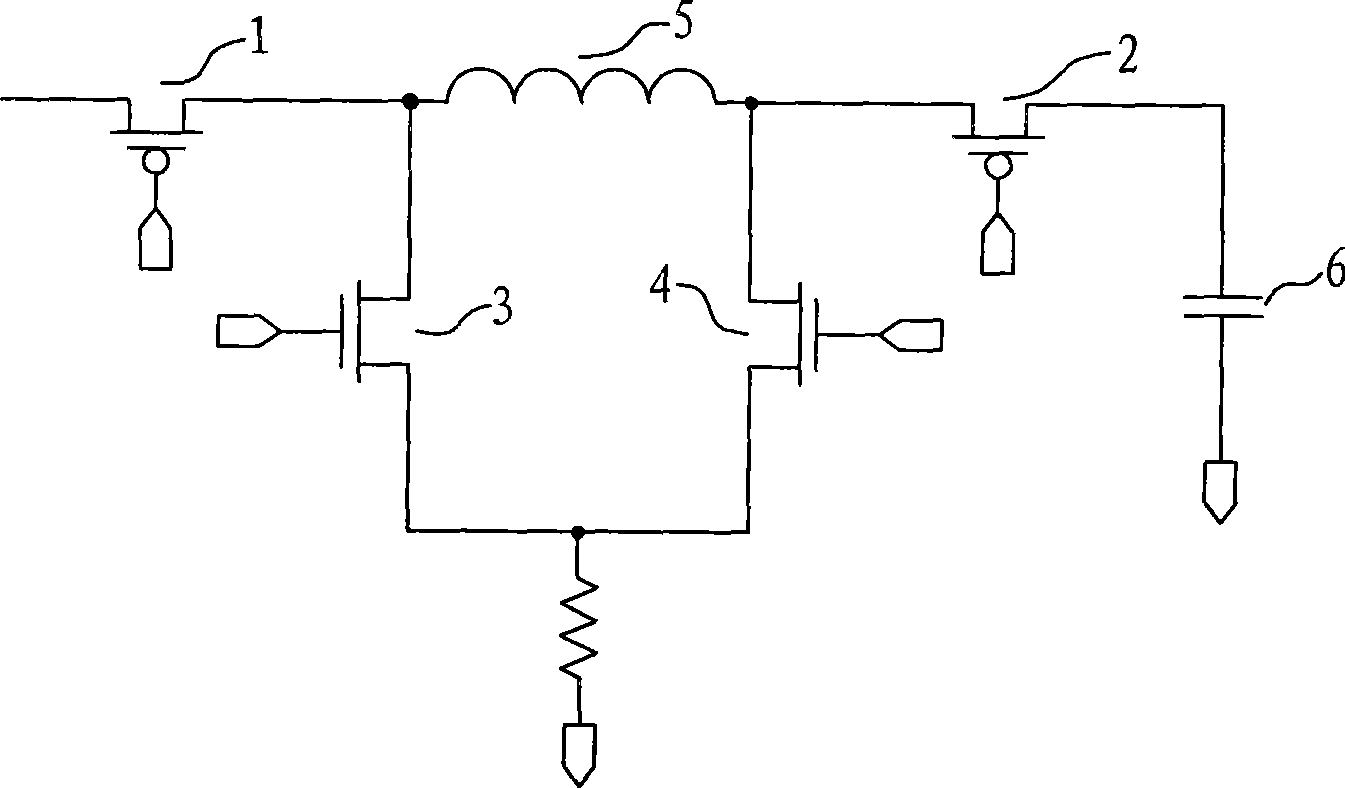

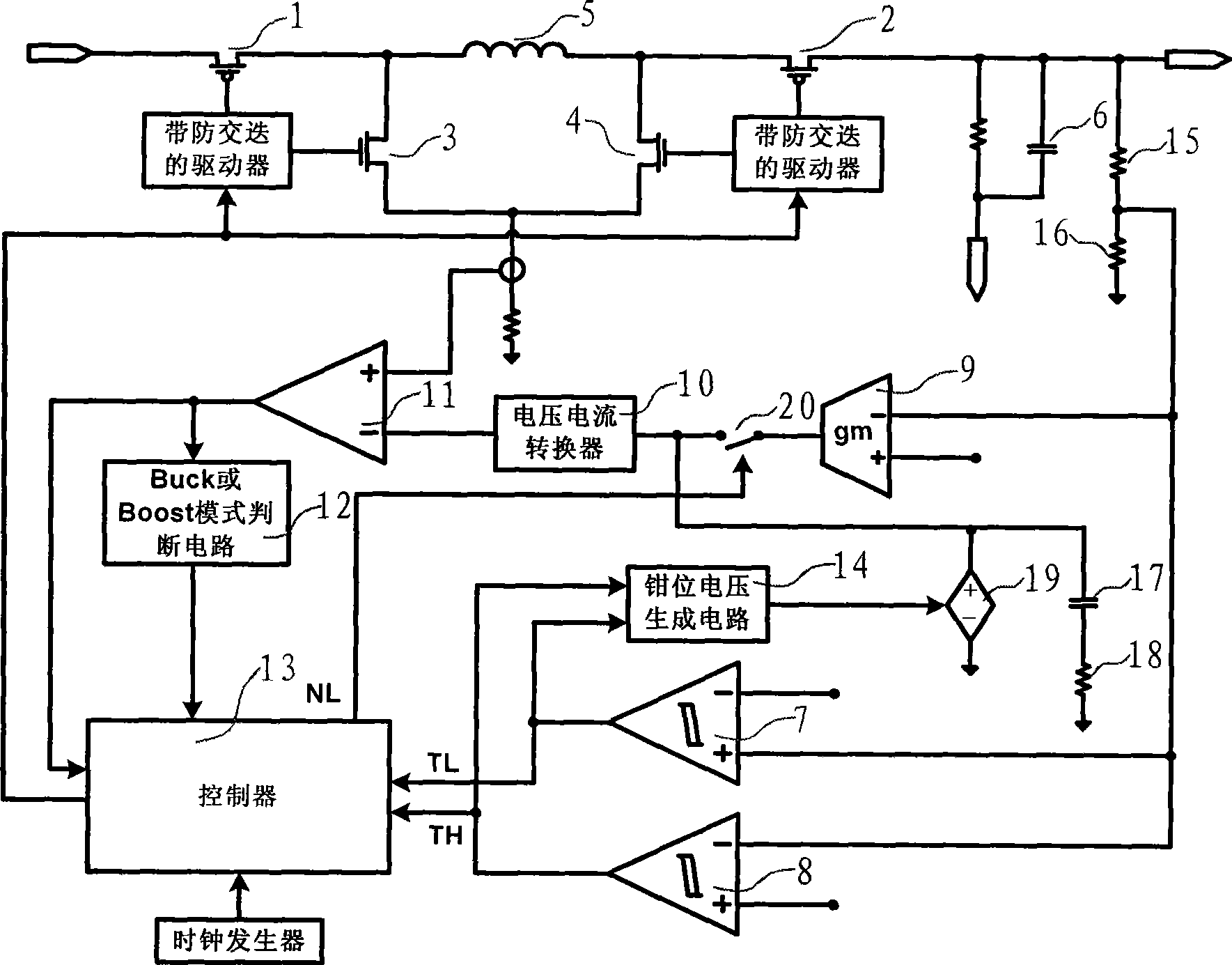

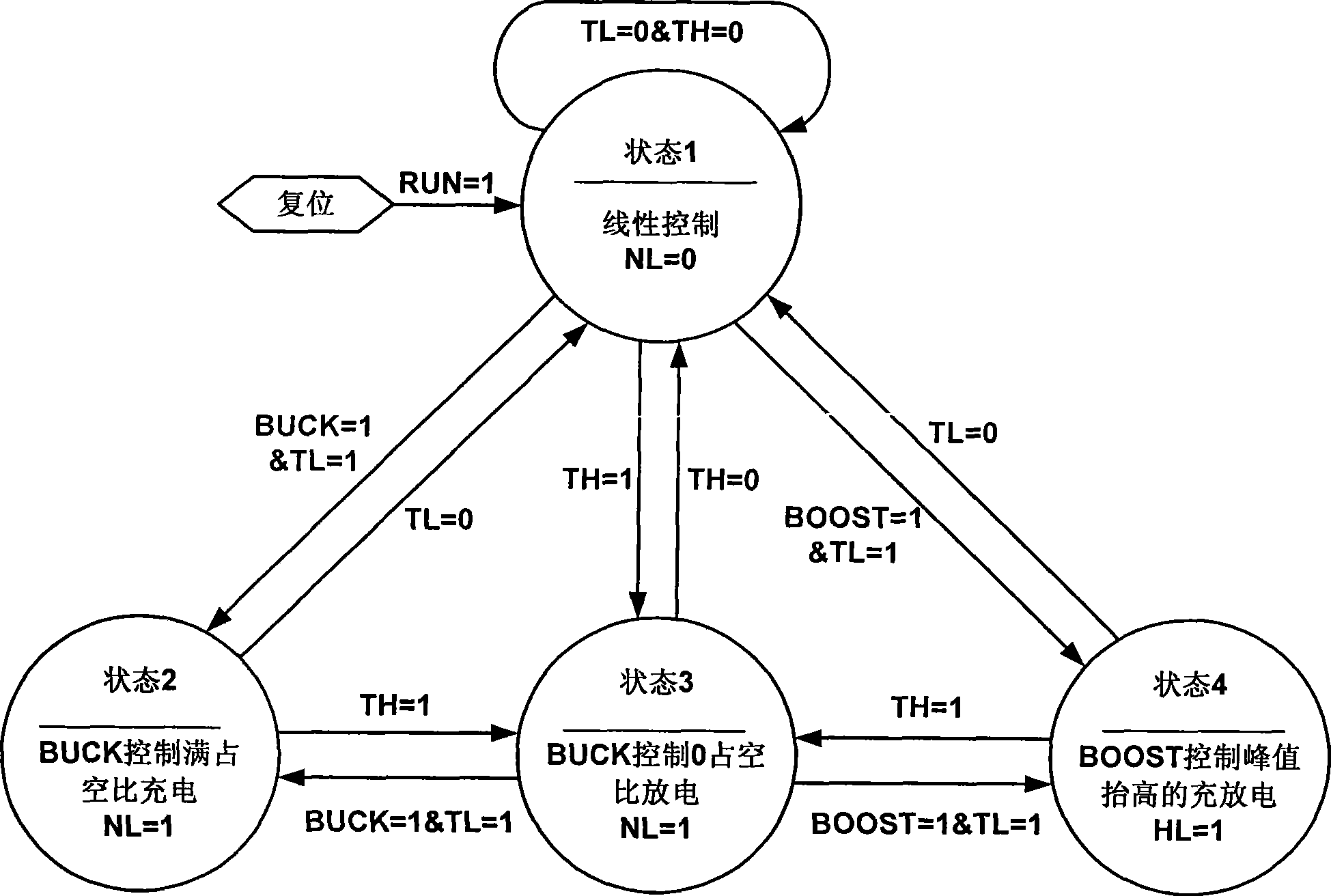

[0028] The control method of the buck-boost DC-DC converter of the present invention adopts current mode control in a steady state, carries out voltage sampling at the voltage output terminal, and inputs the sampling voltage and the reference voltage into the error amplifier, and the output signal of the error amplifier is used as a current comparison The reference input of the amplifier, and a compensation network composed of resistors and capacitors is also connected to the output of the error amplifier. In addition, to judge the working mode of the converter, when the load jumps,

[0029] If working in buck mode:

[0030] When the sampling voltage is lower than the first threshold reference voltage, disconnect the output terminal of the error amplifier from the compensation network and the current comparator, adjust the output voltage of the compensation network to the first clamping voltage, and control the full duty cycle of the converter at the same time Work, after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com