Carbonated beverage and method of producing carbonated beverage

A carbonated beverage and a manufacturing method technology, applied in the directions of food preparation, application, food science, etc., can solve the problems of strong after-sweetness, weak mellow feeling, and no realization, and achieve the effect of reducing after-sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

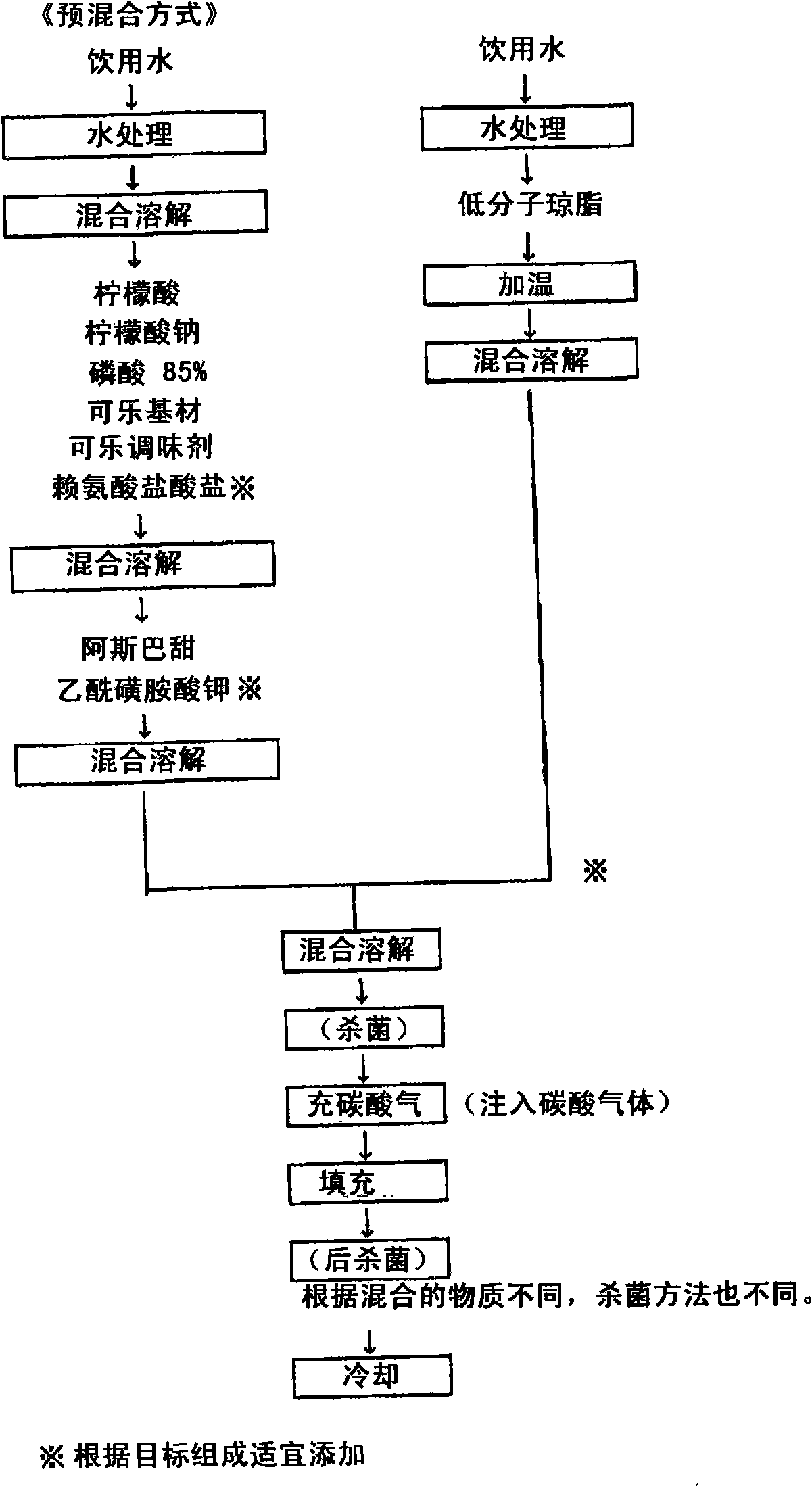

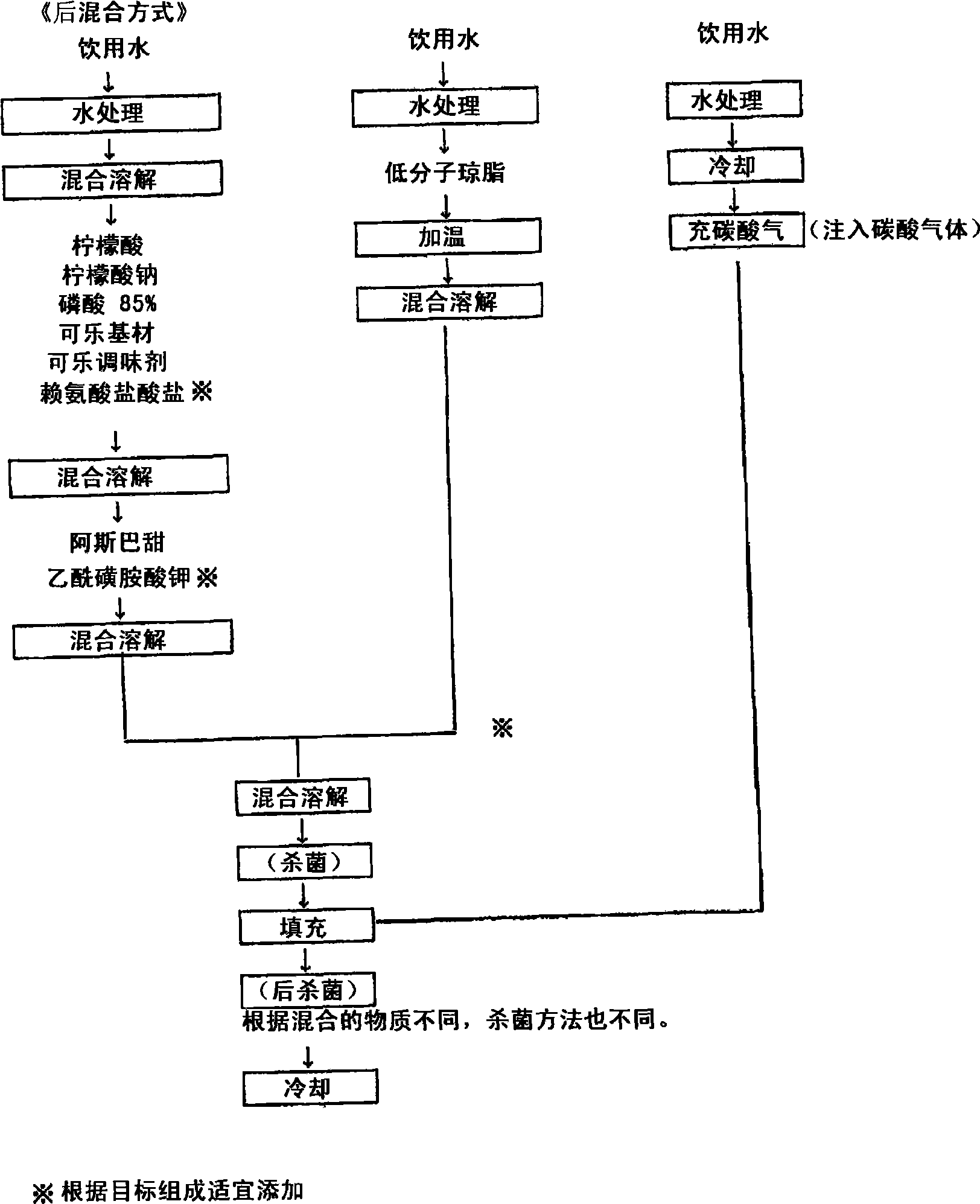

Method used

Image

Examples

Embodiment 1

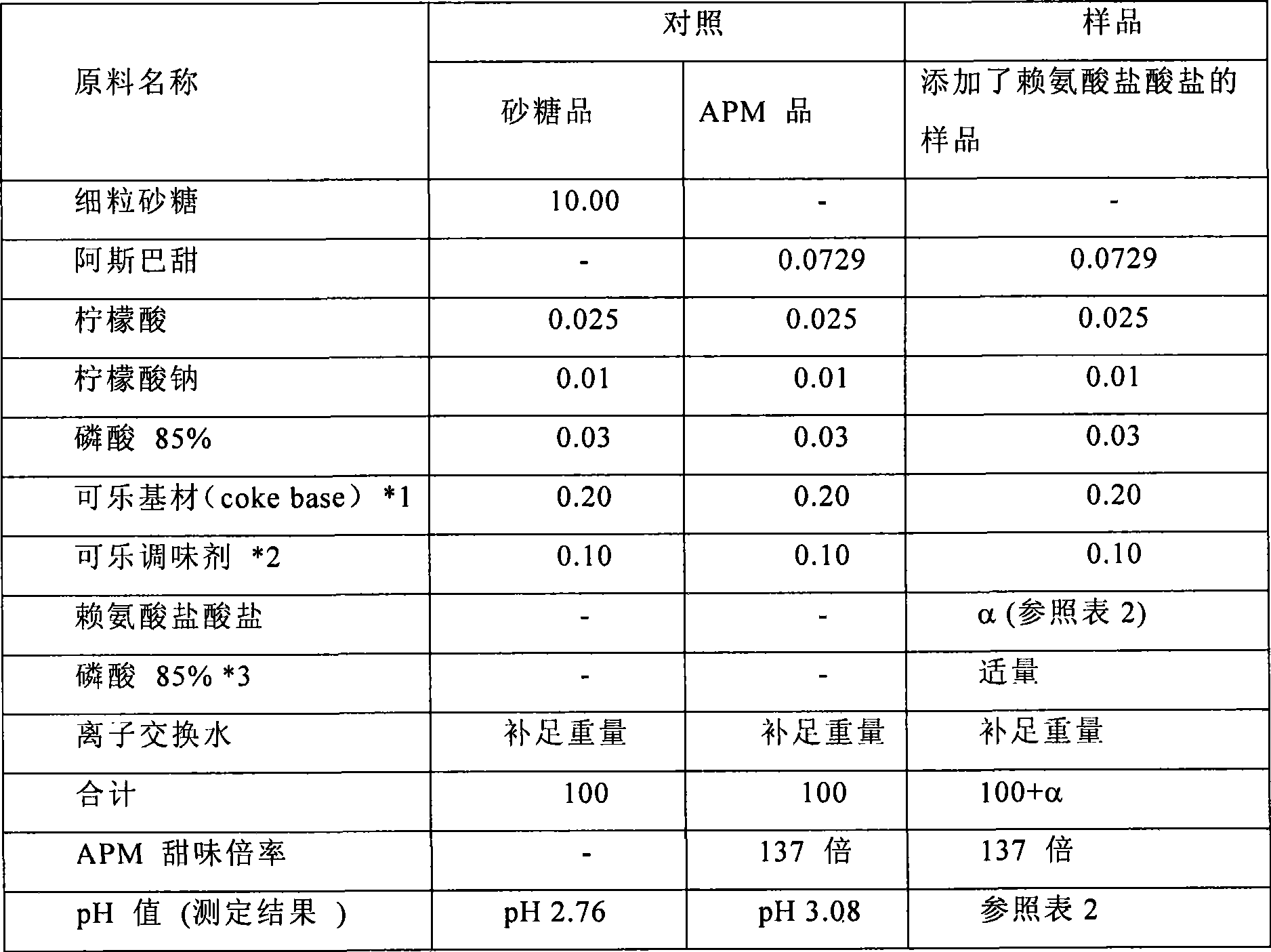

[0047] (embodiment 1) preparation contains the cola carbonated drink of aspartame and lysine hydrochloride

[0048] The mixing composition is shown in Table 1 and Table 2.

[0049] The preparation sequence of cola carbonated beverage is as follows: (1) weigh and mix all raw materials. (2) Only in the sample to which lysine hydrochloride was added to the aspartame product (hereinafter referred to as the APM product), the pH was adjusted to 3.08 (the same value as the APM product) with phosphoric acid. (3) Put 800 g of each sample into the soda water siphon. (4) Cool the soda siphon with ice water for about 1 hour. (5) Inject 8 g of carbon dioxide gas into the siphon of soda water, and close the lid. (6) Chill the soda siphon overnight in the refrigerator. (7) Open the lid of the soda water siphon, dispense about 150g into the can, and carry out canning. The gas internal pressure of the carbonated beverage prepared in this way is 3kgf / cm when measured at 20°C 2 ~4kgf / cm 2...

Embodiment 2

[0071] (embodiment 2) preparation contains the cola carbonated drink of aspartame and low-molecular-weight agar

[0072] The mixing composition is shown in Table 4. Again, the preparation sequence of cola beverage is the same as embodiment 1. Low-molecular-weight agar has the effect of reducing the after-sweetness of aspartame, imparting mellowness, enhancing the first-sweetness, and delicacy close to sugar.

Embodiment 3

[0073] (embodiment 3) preparation contains the cola carbonated drink of aspartame, lysine hydrochloride and low molecular weight agar

[0074] The mixing composition is shown in Table 4. Again, the preparation sequence of cola beverage is the same as embodiment 1. The combination of lysine hydrochloride and low-molecular-weight agar has the effect of reducing the after-sweetness of aspartame, imparting mellowness, enhancing the first-sweetness, and delicacy close to sugar.

[0075] Table 4: Mixture of cola carbonated drinks (sample)

[0076]

[0077] Units in the table (g)

[0078] * 1 Takasago Fragrance Industry Co., Ltd., Coke Base W-6521

[0079] * 2 Takasago Flavor Industry Co., Ltd., Cola Flavor M-80051

[0080] * 3 Ina Food Industry Co., Ltd., Ultra Agar "I-na"

[0081] The average molecular weight of ULTRA agar "イ—ナ" is about 50,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com