Fastening arrangement for a gas tank of a motor vehicle

A technology for fixing devices and gas storage tanks, which is applied in the field of vehicles, can solve problems such as time consumption, and achieve the effects of saving parts, saving material costs, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

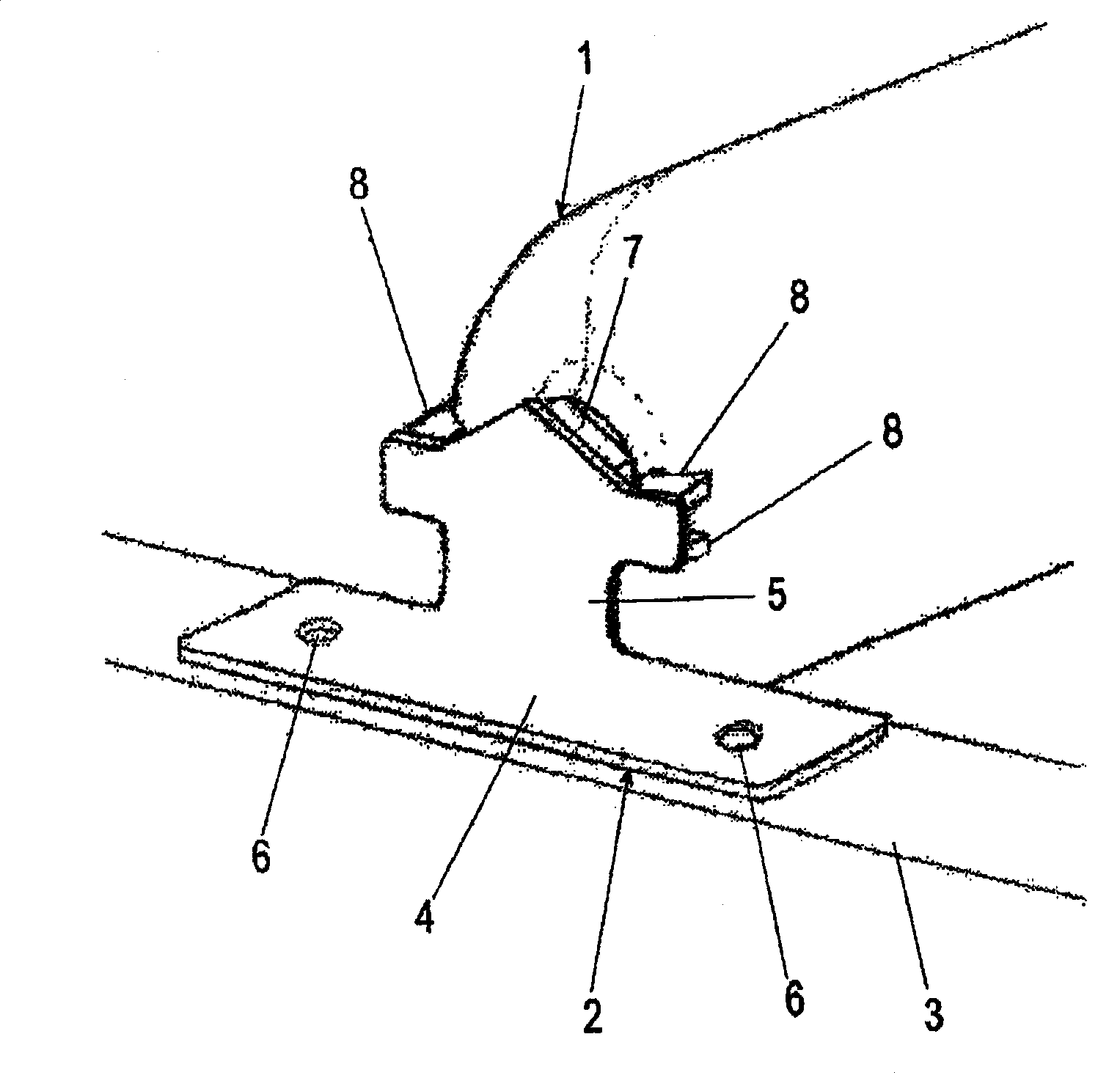

[0038] Thus, a preferred embodiment of the gas tank fastening device according to the invention for a vehicle that can be powered by gaseous fuel comprises a cylindrical gas tank, indicated overall by the reference numeral 1 and shown here only partially. The gas tank 1 is provided with a hole for accommodating a gas valve for controlling the inflow and outflow of gaseous fuel in the gas tank. The gas valve is designed as an internal valve, wherein the valve body has a control device for controlling the gas valve, and other components, such as a manual shut-off valve and various safety devices, and most of the valve body is installed in the inner cavity of the gas container 1 .

[0039] The valve body is provided for this purpose with an external thread which is screwed into an opening provided with an internal thread of the gas tank 1 . exist figure 1 Only the end 7 ("valve body head") of the valve body of the gas valve protruding from the gas tank 1 can be seen in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com