Shaft seal device

A technology for shaft seals and sealing parts, which is applied to engine seals, engine components, mechanical equipment, etc. It can solve problems such as difficult removal, rusting of the metal ring 210, leakage of sealed fluid, etc., and achieves simple assembly structure and small elastic deformation , the effect of preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

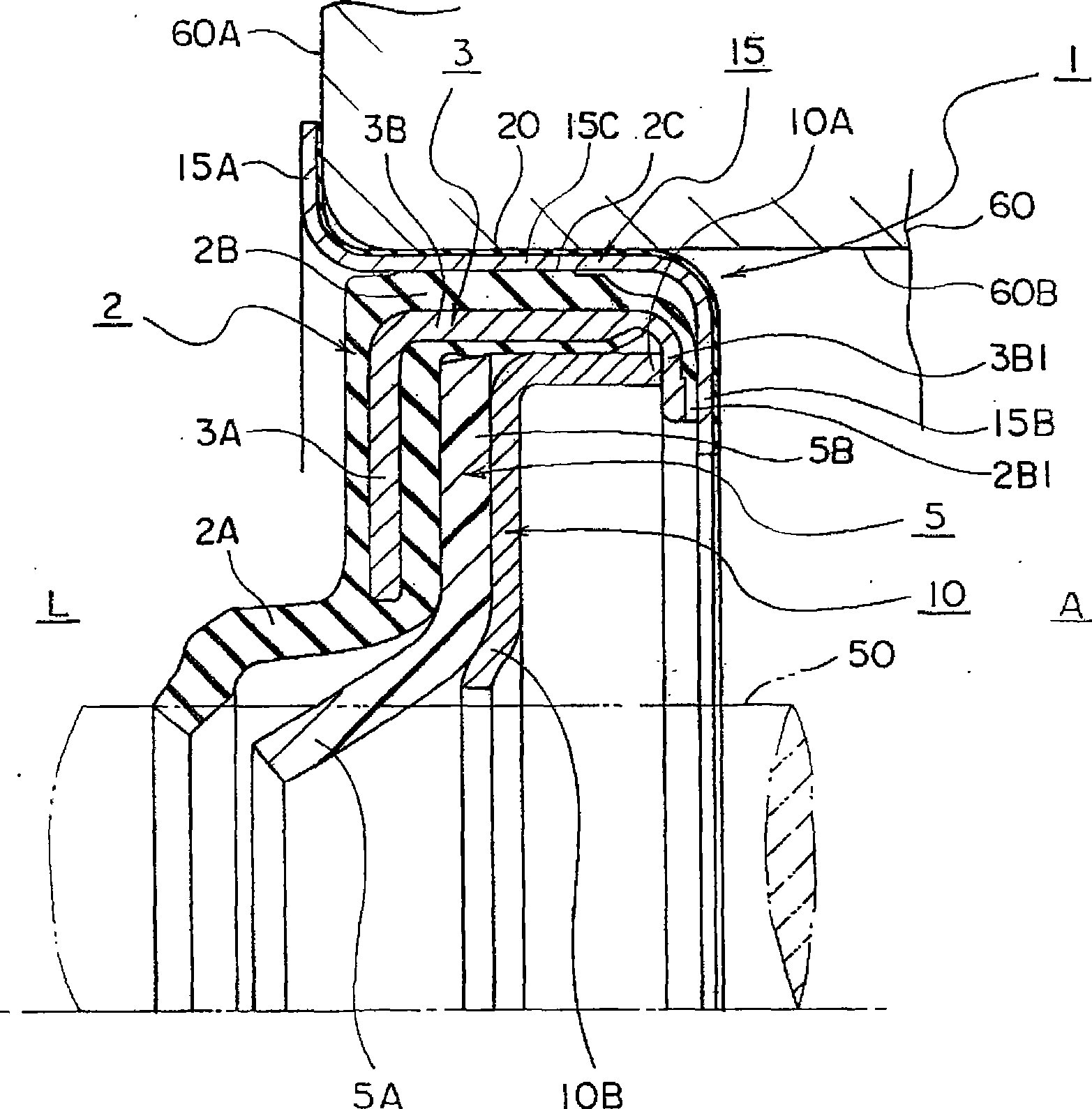

[0056] First, Embodiment 1 of the shaft sealing device 1 of the present invention will be described. figure 1 It is a sectional view of one side of the shaft sealing device 1 . figure 2 for will figure 1 A cross-sectional view of one side of the state where the shaft sealing device is inserted into the rotary shaft 50 . refer to the figure 1 and figure 2 Be explained. The rotary shaft 50 is attached to a hole forming surface (hereinafter referred to as a hole) 60B provided on the cover 60 . The sealed fluid existing in the equipment interior L between the hole 60B and the rotary shaft 50 is sealed by the shaft sealing device 1 . The fluid to be sealed is, for example, a coolant or the like with temperature and pressure. In a specific example, a cooling fluid or the like for cooling a radiator or the like is sealed.

[0057] The first sealing part 2 is formed with a cylindrical fitting part 2B, a first sealing lip 2A extending radially inward at one end of the fitti...

Embodiment 2

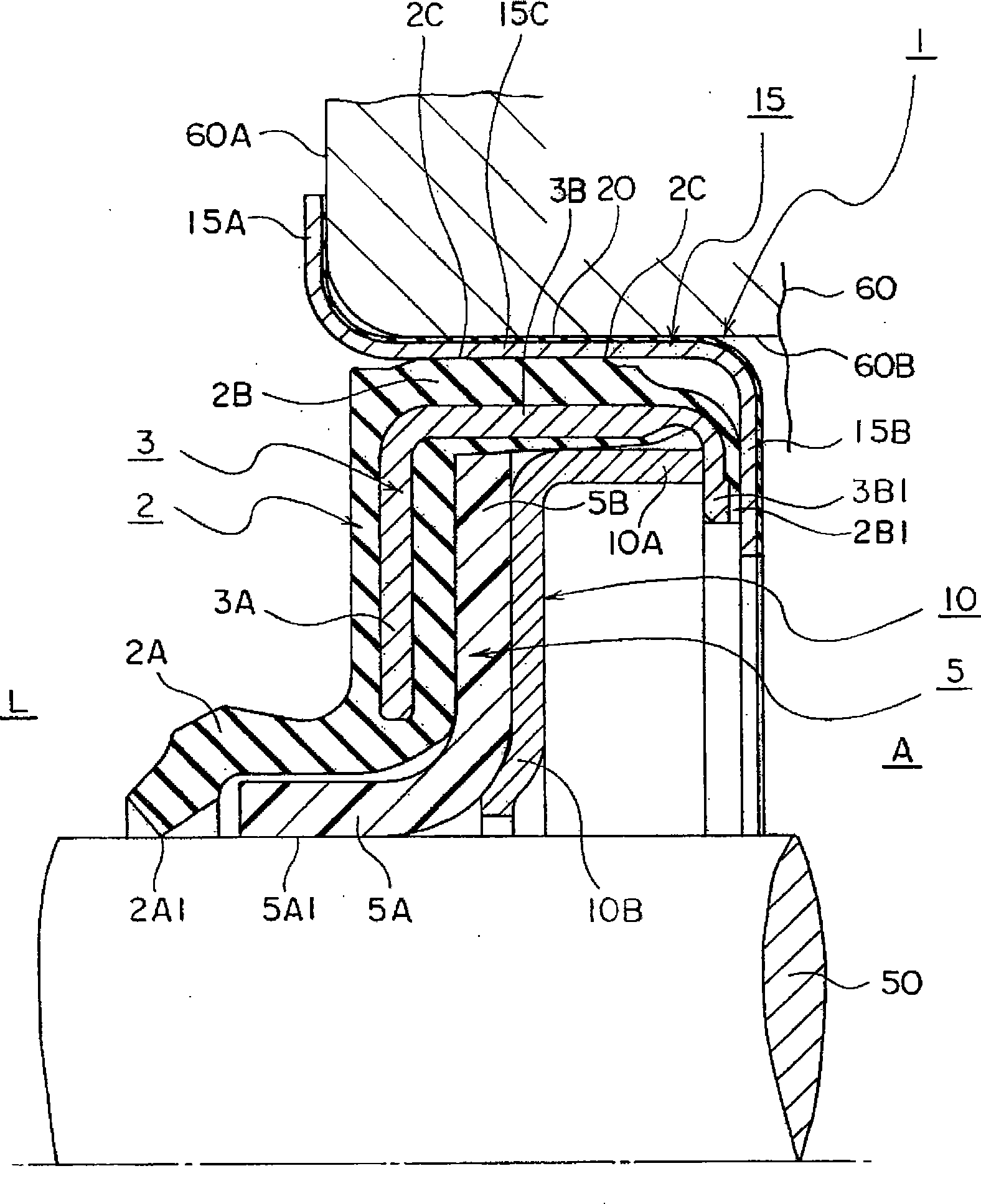

[0065] Hereinafter, the shaft sealing device 1 according to the second embodiment of the present invention will be described. image 3 It is a sectional view of one side of the shaft sealing device 1 of the second embodiment. exist image 3 In this case, the hole 60B of the seal cover 60 is not provided with a stepped positioning portion for positioning and fixing the shaft seal device 1 in the axial direction. In this shaft seal device 1, with figure 1 The difference is that the connecting parts 2B1 and 3B1 of the first sealing part 2 are compared to figure 1 The connecting parts 2B1 and 3B1 of the first sealing part 2 are arranged on the side of the first engaging part 15A. Furthermore, the second connecting portion 3B1 is formed in a flange shape from the cylindrical portion 3B of the reinforcement ring 3 toward the same direction as the first engaging portion 15A. The connection parts 2B1 and 3B1 of the first seal part 2 are formed by the second connection part 3B1 o...

Embodiment 3

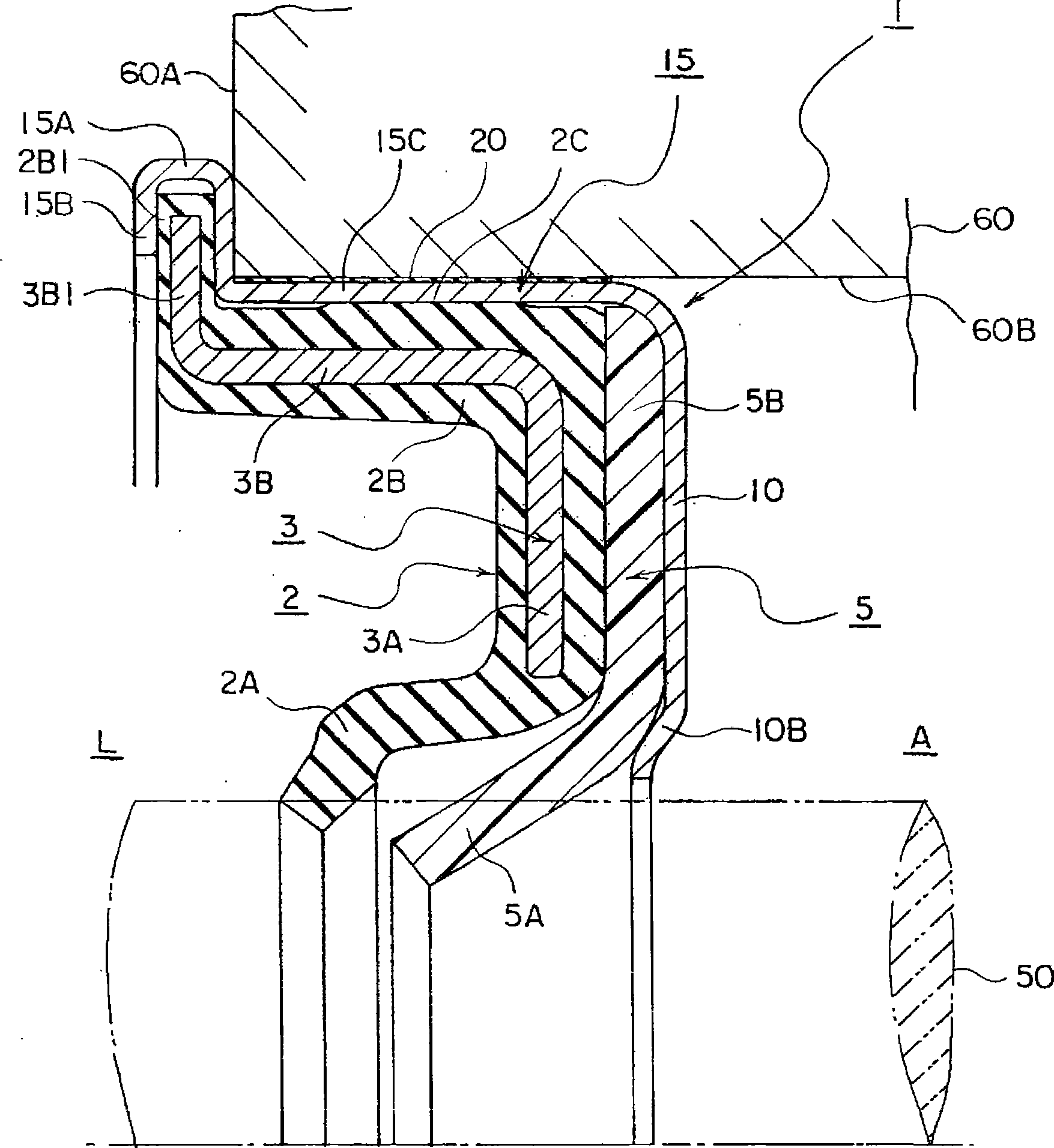

[0069] Hereinafter, the shaft sealing device 1 according to the third embodiment of the present invention will be described. Figure 4 It is a sectional view of one side of the shaft sealing device 1 of the third embodiment. exist Figure 4In this case, the step positioning portion for fixing the shaft seal device 1 in the axial direction is not provided in the hole 60B of the seal cover 60 . In this shaft seal device 1, with figure 1 The difference is a modified embodiment in which the snap ring (also referred to as snap plate) 15 and the reinforcement ring 3 are integrated. The reinforcement ring 3 is with figure 1 The reinforcement rings 3 are roughly the same shape. And, snap ring 15 and Figure 4 The reinforcement ring 3 shown in combination, with figure 1 A portion corresponding to the fitting portion 15C of the reinforcing ring 3 also serves as the cylindrical portion 3B of the reinforcing ring 3 . That is, the snap ring 15 is provided with a first snap portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com