Rotary table type machine for automatic continuous production of balls

A turntable type, ball machine technology, applied in the field of cooking machinery, can solve problems such as noise productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

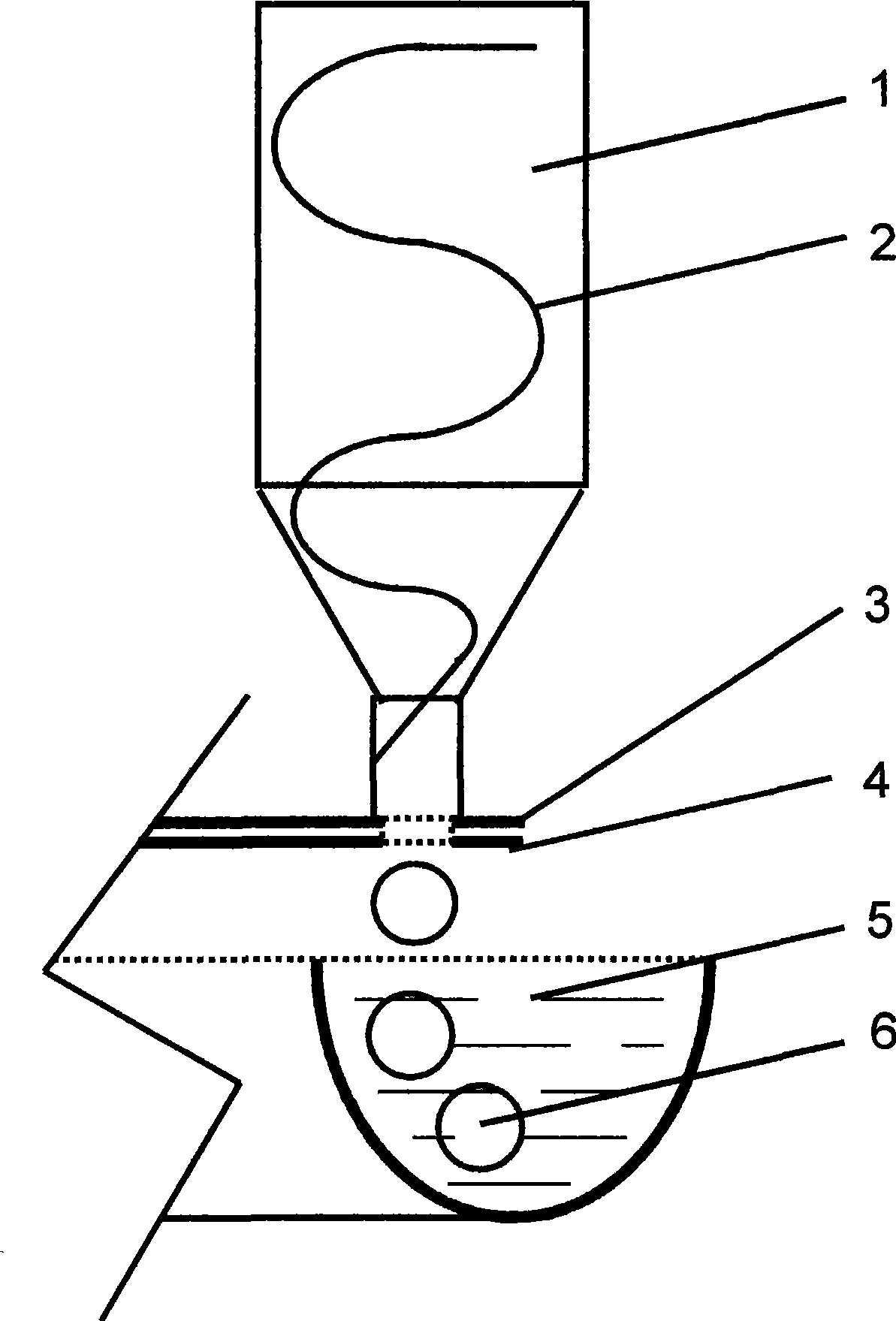

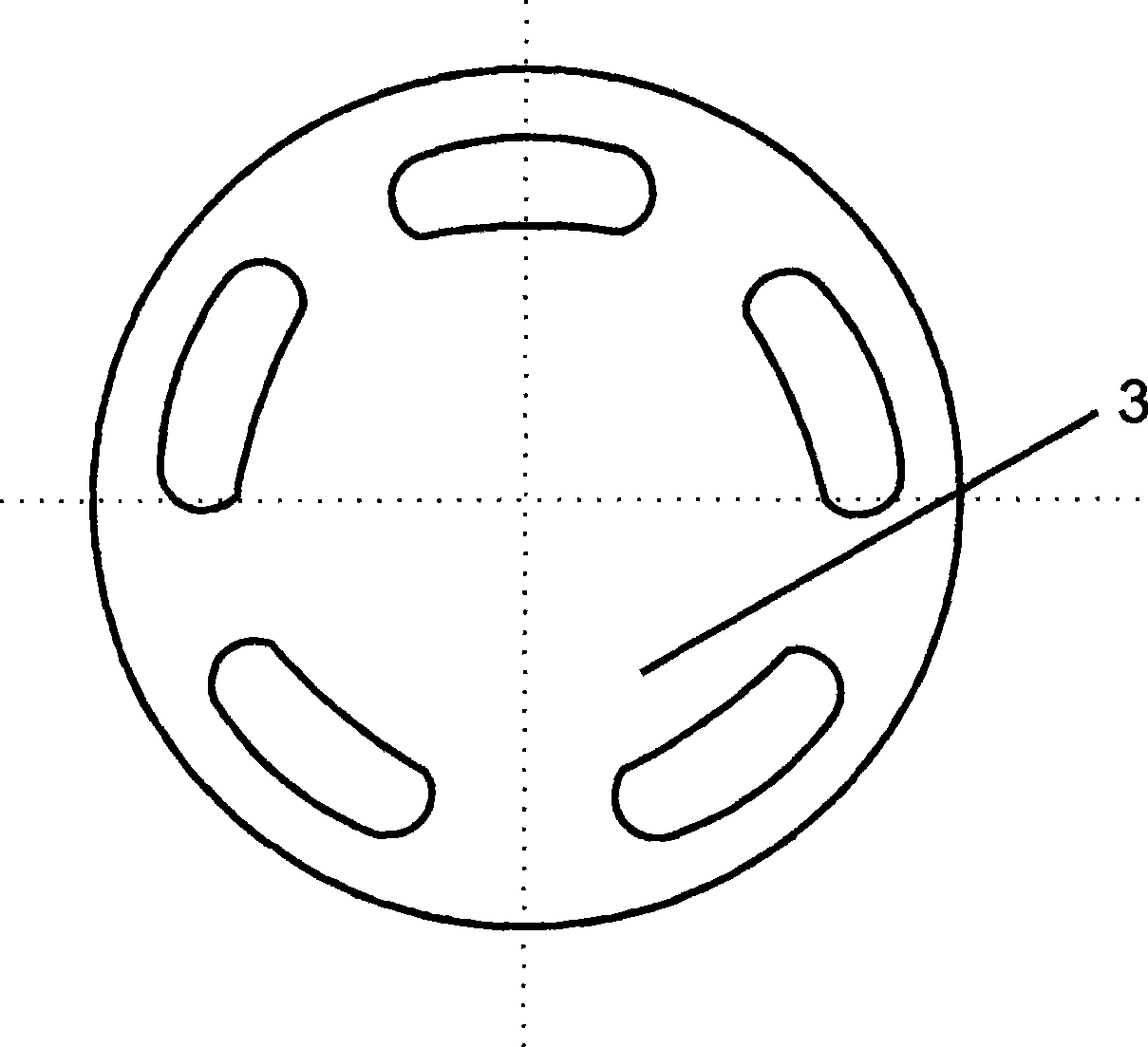

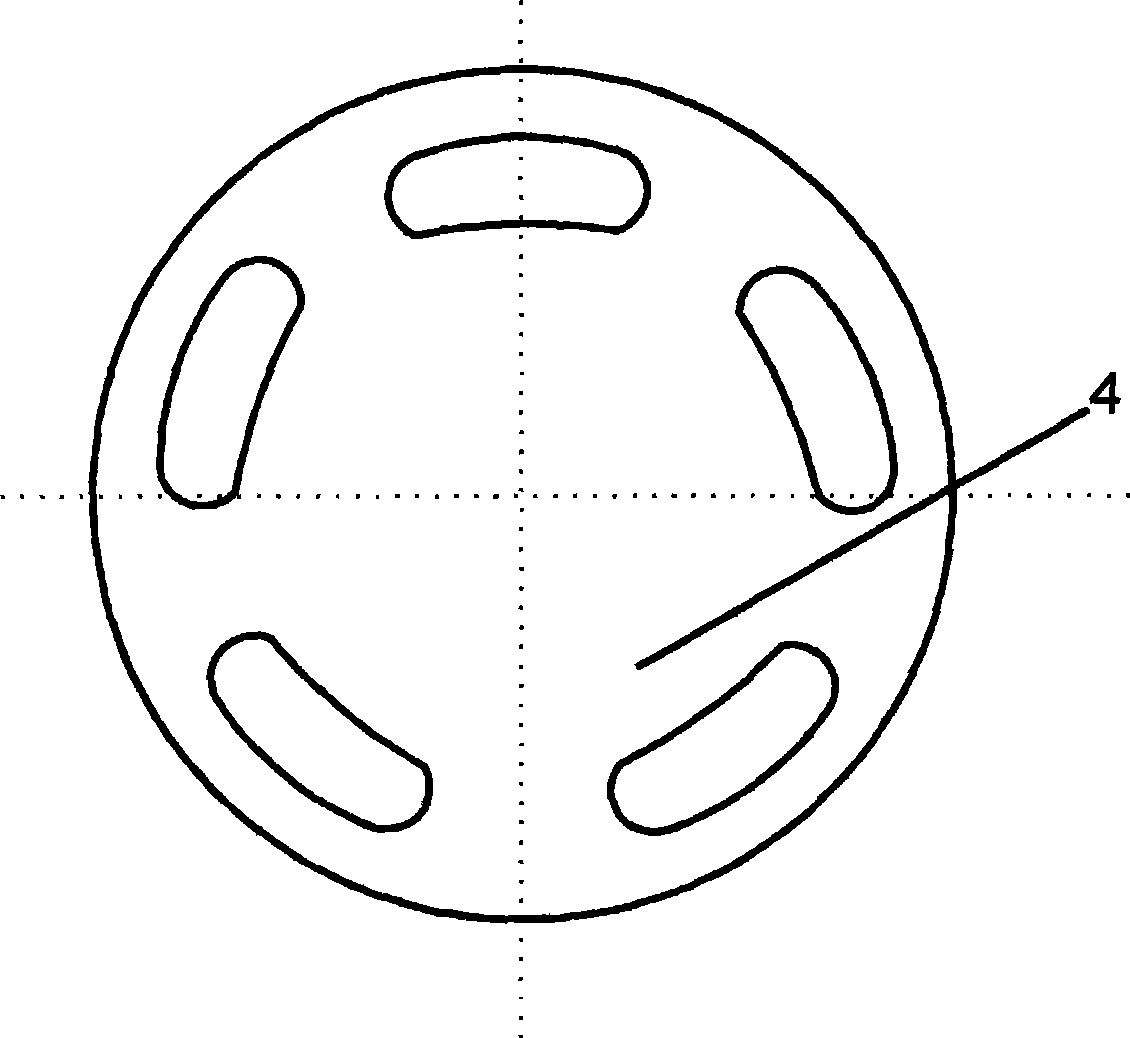

[0015] exist figure 1 , figure 2 and image 3 In the schematic diagram of the rotary table type automatic continuous production meatball machine shown, the present invention is to overcome the problems of high noise and vibration of the original machine and low productivity. It is composed of a raw material cylinder 1, a conveyor 2, a first filling plate 3 and a second filling plate 4, and each of the first filling plate 3 and the second filling plate 4 has a number corresponding to the number of units. Two circular arc long holes with the same specification, their distribution diameters are the same, driven by a motor, the rotation directions of the two discs are opposite, and the direction of rotation of the two discs is reversed with a 1:1 gear in the transmission chain, and the arcs on the two filling plates When the long holes intersect, the center is aligned with the discharge opening of the raw material cylinder 1 .

[0016] When working, put the stirred meat stuffi...

Embodiment 2

[0020] At the outlet of the bottom of the raw material cylinder, the same upper and lower two large disc-type filling plates as in the first embodiment, the difference from the first embodiment is that the upper and lower two large disc-type large filling plates are not one forward and the other Reverse asynchronous rotation, but do the reciprocating motion that rotates in the opposite direction until the distance of a ball is stopped, and then turns back to the distance of a ball and then stops. There is a hole on each plate, when the holes on the two discharge plates When the timing is relative to the discharge port of the bucket, the stuffed meat passes through, and the discharge stops when the two holes miss, and the stuffed meat extruded is formed into balls 6 in the hot water 5 below.

Embodiment 3

[0022] At the outlet at the bottom of the raw material cylinder 1, there are two large disc-type large filling plates up and down the same as in embodiment one. The difference from embodiment one and implementation two is that the two large disc-type large filling plates up and down are not a front To the other reverse asynchronous rotation, but the lower large disc type filling plate 4 is stationary, only the upper large disc type filling plate 3 rotates circularly or only has the distance of a meatball to reciprocate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com