Method for controlling model building in leaf moisture-regaining process of tobacco shred production

A control method and blade technology, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as large blade fluctuations and affect product quality, and achieve the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

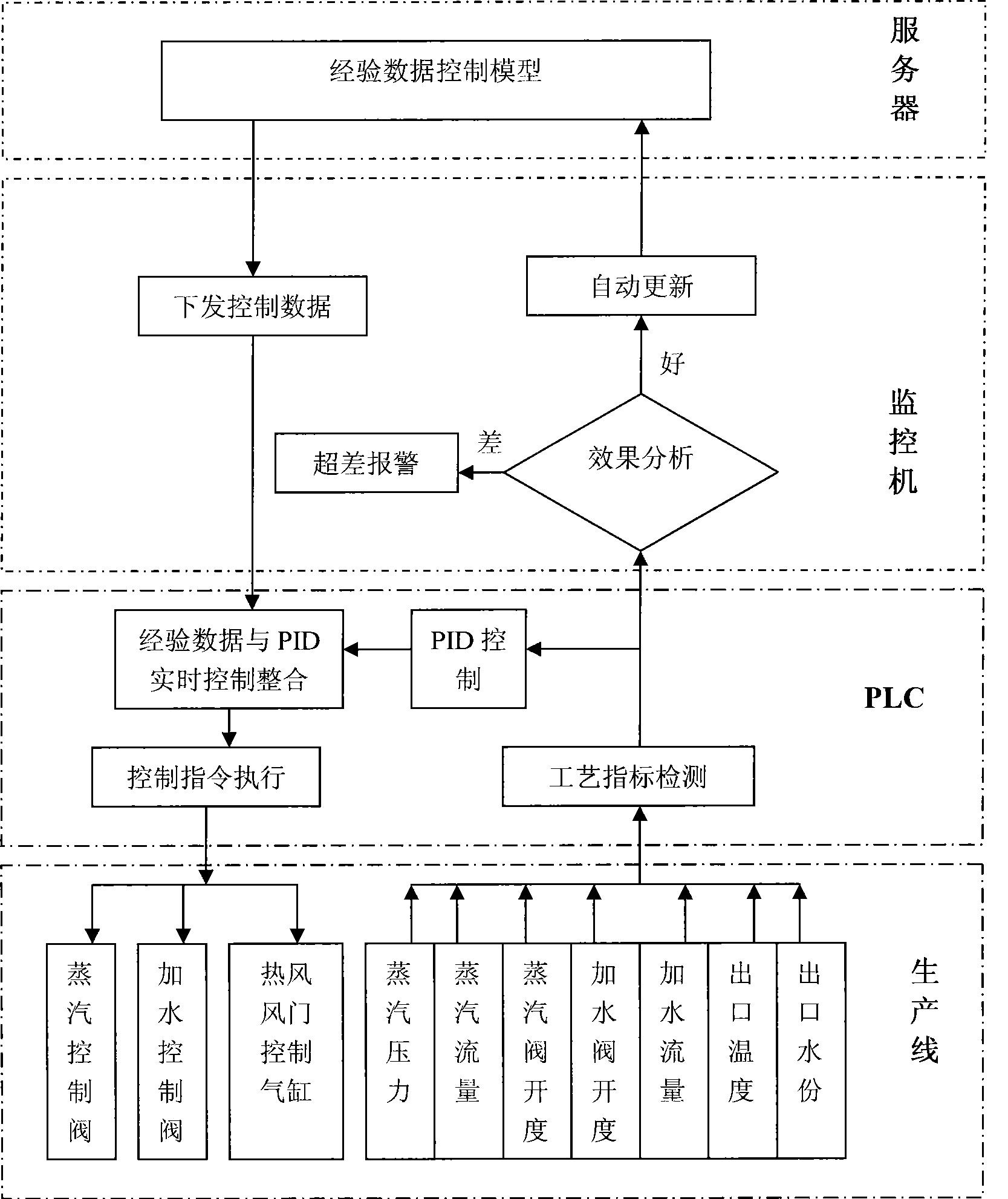

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] figure 1 Among them, steam pressure gauge, steam flow meter, water adding flow meter, infrared thermometer and infrared moisture meter are installed on the blade dampening machine to detect steam pressure, steam flow, steam valve opening, water adding valve opening, water adding flow, Outlet temperature, outlet moisture indicators, and send these indicators to the PLC controller.

[0013] The PLC controller is directly connected to the detection element and the control element, collects various detection data in real time, and divides the signal of the process index into two channels, one of which is sent to the monitoring machine. After analyzing the results, the results that meet the requirements are sent to the server to form empirical data. Control the model, and alarm if the data does not meet the requirements. The server sends the data to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com