Novel abrasion-proof circulating fluidized bed

A circulating fluidized bed, a new type of technology, applied in the field of circulating fluidized bed, to achieve the effects of low wear, reasonable design and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

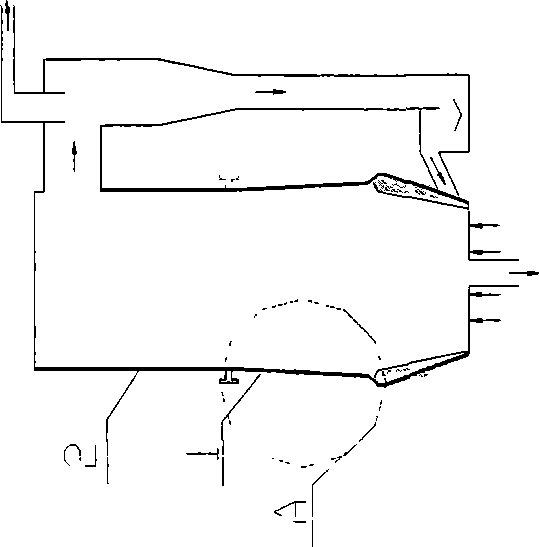

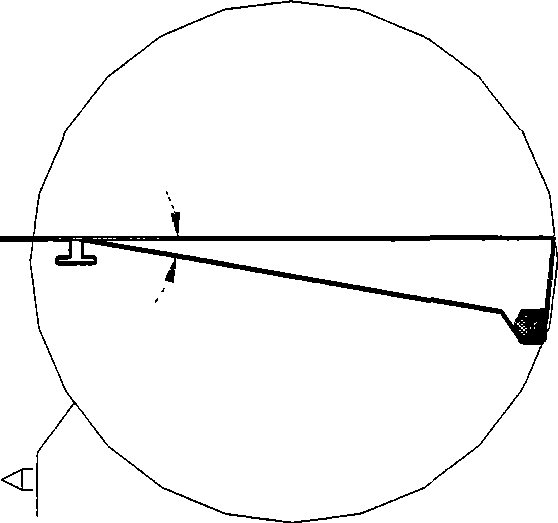

[0010] Embodiment 1, accompanying drawing have provided the specific embodiment of the present utility model, according to figure 1 , figure 2 , image 3 As shown, the furnace body of the utility model is a circular furnace body, and 1 in the figure is a membrane water-cooled wall in the recirculation zone. The water-cooled wall 1 and the membrane-type water-cooled wall 2 in the advection area are excessively connected in a streamlined manner.

Embodiment 2

[0011] Embodiment 2, body of heater of the present utility model is square body of heater, as Figure 4 As shown in the figure, 1 is the membrane water cooling wall in the recirculation area, the membrane water cooling wall 1 in the recirculation area is inclined outward, and the inclination angle is 0.8 degrees, and the membrane water cooling wall 1 in the recirculation area is streamlined with the membrane water cooling wall in the advection area For over-connection, the four corners of the membrane water wall in the recirculation area are sealed and connected by fins 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com