Semi-active vibration-isolating platform employing magnetorheological damping technology

A technology of magnetorheological damping and magnetorheological dampers, which is applied in the field of semi-active vibration isolation platforms, can solve problems such as insufficient reliability and increased quality, and achieve the effects of reducing quality, improving vibration control accuracy, and preventing lateral shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

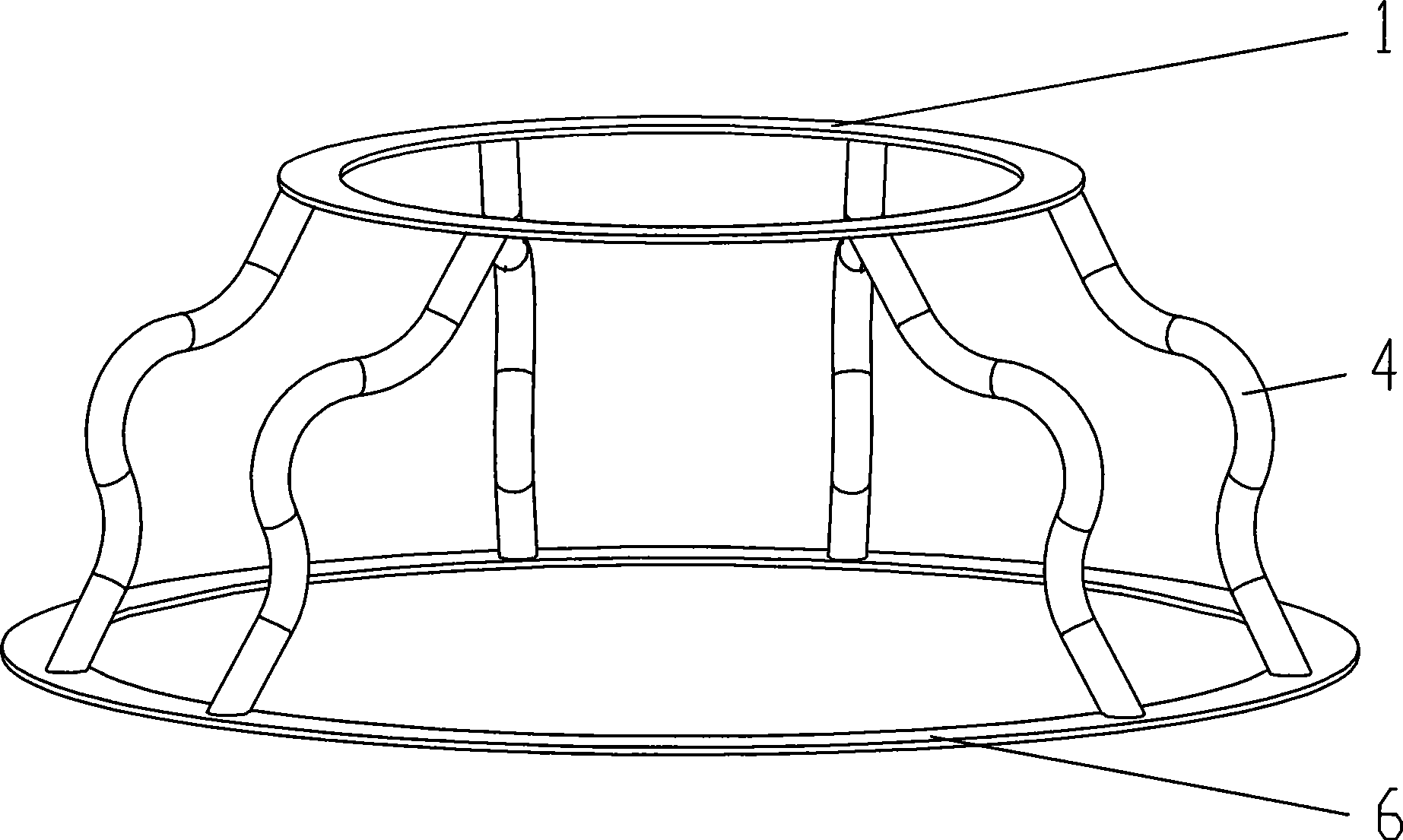

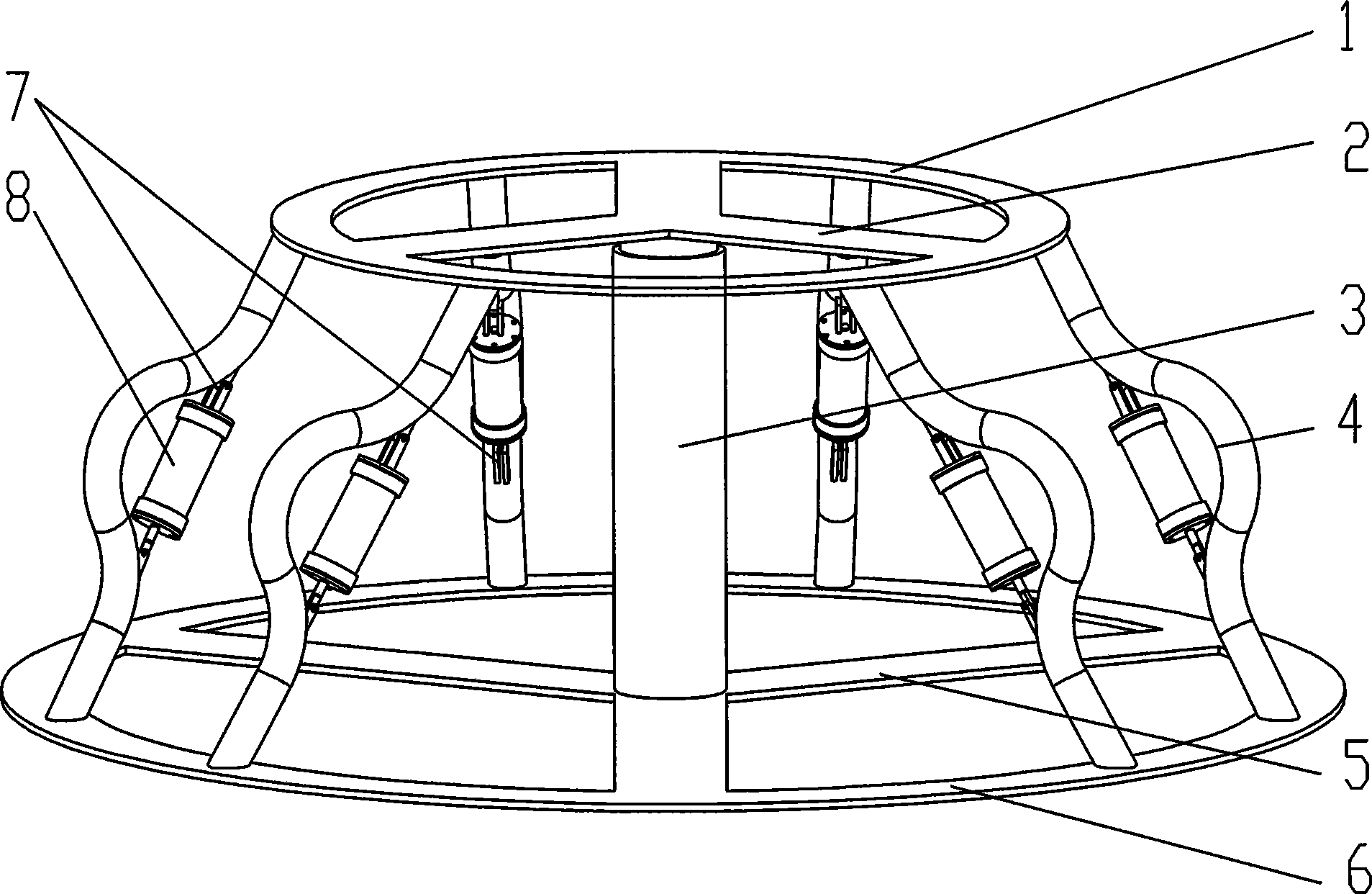

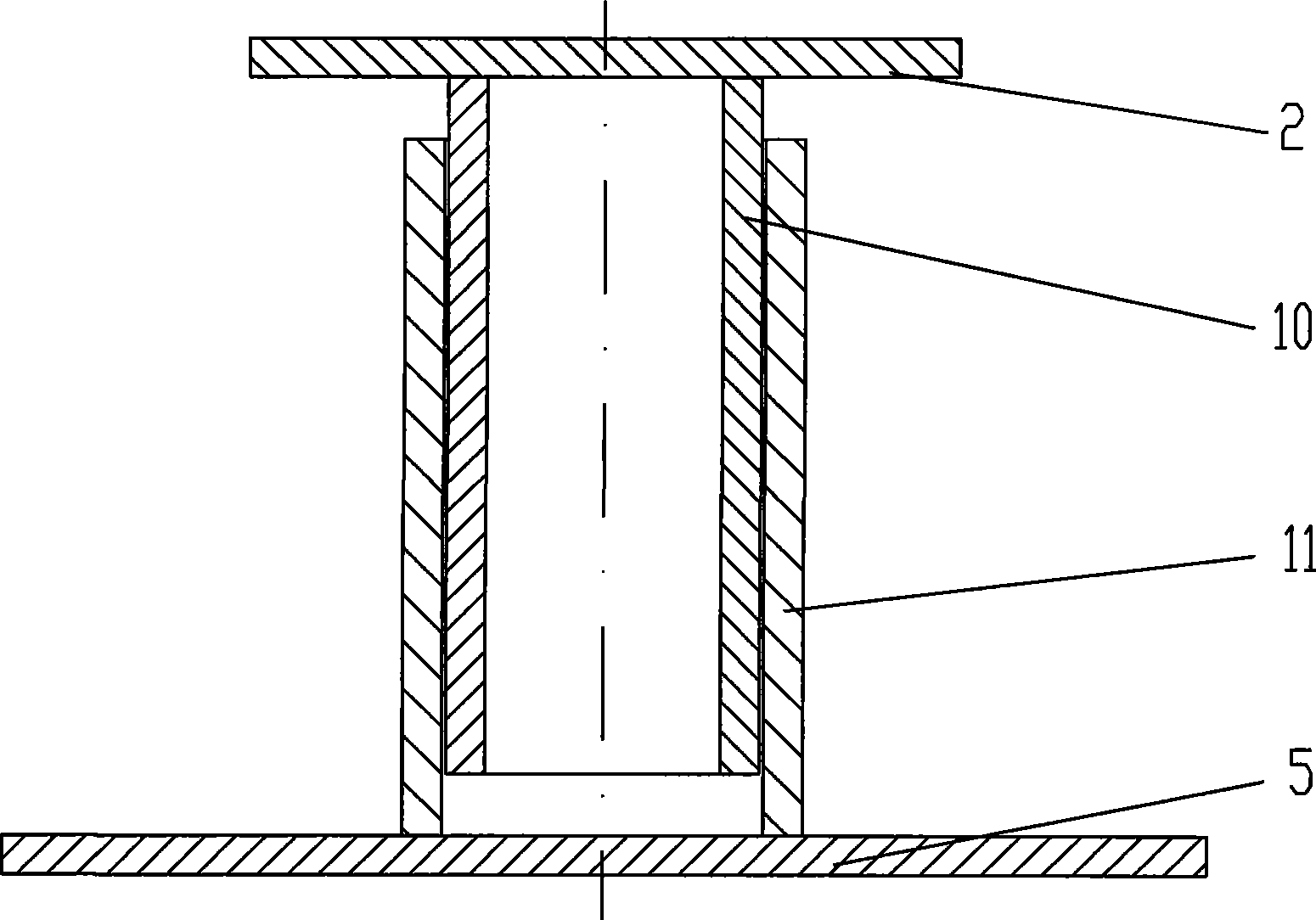

[0007] Specific implementation mode one: (see Figure 1 ~ Figure 3 ) The semi-active vibration isolation platform of this embodiment is composed of a passive vibration isolation device, a semi-active control device and an anti-sway device 3, and the passive vibration isolation device includes an upper platform 1, a lower platform 6 and at least three elastic support rods 4, so The above-mentioned upper platform 1 and the lower platform 6 are circular rings, at least three elastic support rods 4 are installed between the upper platform 1 and the lower platform 6, and the upper end and the lower end of each elastic support rod 4 are connected with the upper platform respectively. The lower end surface of 1 is fixedly connected with the upper end surface of lower platform 6, and the middle part of each elastic support rod 4 is bent into an outwardly convex arc; the semi-active control device is composed of a plurality of magneto-rheological dampers 8 and a plurality of hinges 7, ...

specific Embodiment approach 2

[0008] Specific implementation mode two: (see figure 1 ) The number of elastic support rods 4 in this embodiment is three to six. With such a setting, the reliability is higher. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: (see figure 1 ) The elastic support rod 4 of this embodiment is made of carbon fiber reinforced aluminum composite material. The tensile strength of carbon fiber reinforced aluminum composite material reaches 665MPa, and the density is 2400kg / m 3 , the modulus of elasticity reaches 210GPa. Such setting better meets the requirements of high strength, light weight and low cost of the aerospace structure. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com