Three-phase multi-functional mixed combustion furnace

A co-combustion furnace, an all-round technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of insufficient heat source, incomplete combustion of gas in the combustion furnace, economic loss, etc., and achieve the effect of excellent working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

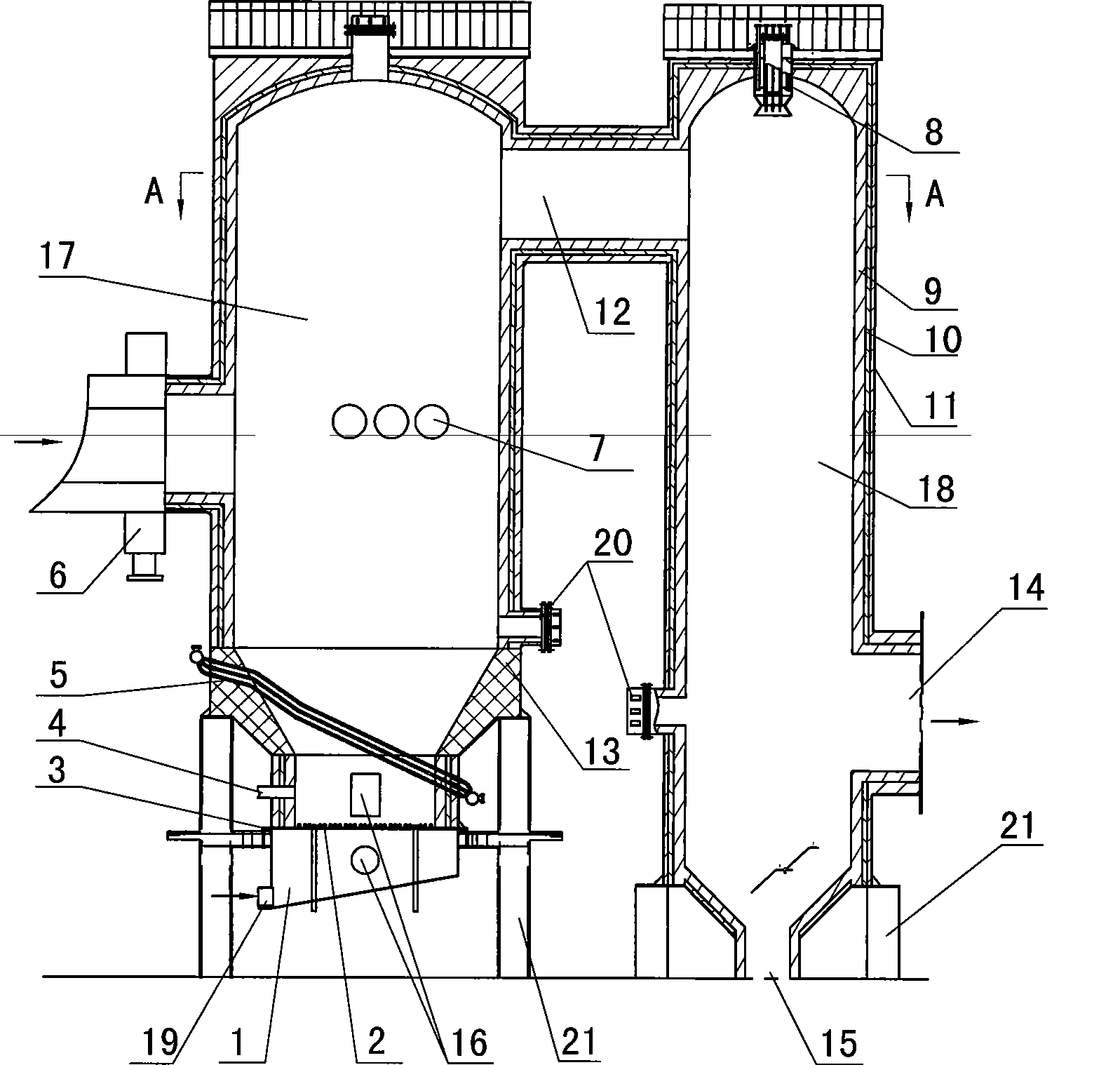

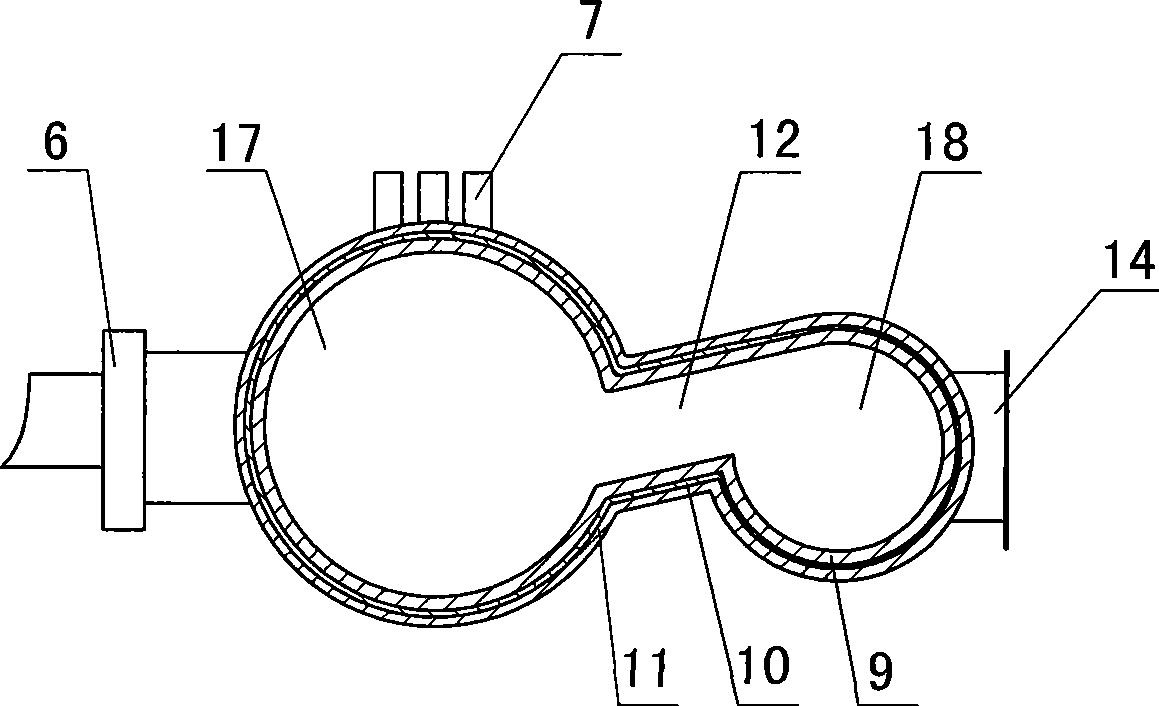

[0017] exist Figure 1-2 In the shown embodiment: the co-combustion furnace includes a main combustion furnace 17 for burning coal and waste gas and a secondary combustion furnace 18 for burning waste liquid, and the upper parts of the main combustion furnace 17 and the secondary combustion furnace 18 communicate tangentially through the flue 12; The bottom of the main combustion furnace 17 is provided with an air chamber 1, and the air chamber 1 is provided with an air inlet 19 and a manhole 16 for connecting the blower. The wind cap 2 for supplying air to the coal-burning area; the coal-burning area in the middle and lower part of the main combustion furnace 17 furnace is provided with a mechanical coal supply port 4 and a manhole 16, and a plurality of water pipes 5 forming a water cycle with the outside are arranged obliquely. The horizontal is at an angle of 30°, which is used to reduce the temperature of the combustion chamber and prevent coking; the middle part of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com