Etching method, etching apparatus, computer program and storage medium

A technology of etching and etching gas, which is applied in the direction of discharge tubes, electrical components, semiconductor/solid-state device manufacturing, etc., to achieve excellent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, an embodiment of an etching method, an etching apparatus, a computer program, and a recording medium of the present invention will be described with reference to the drawings.

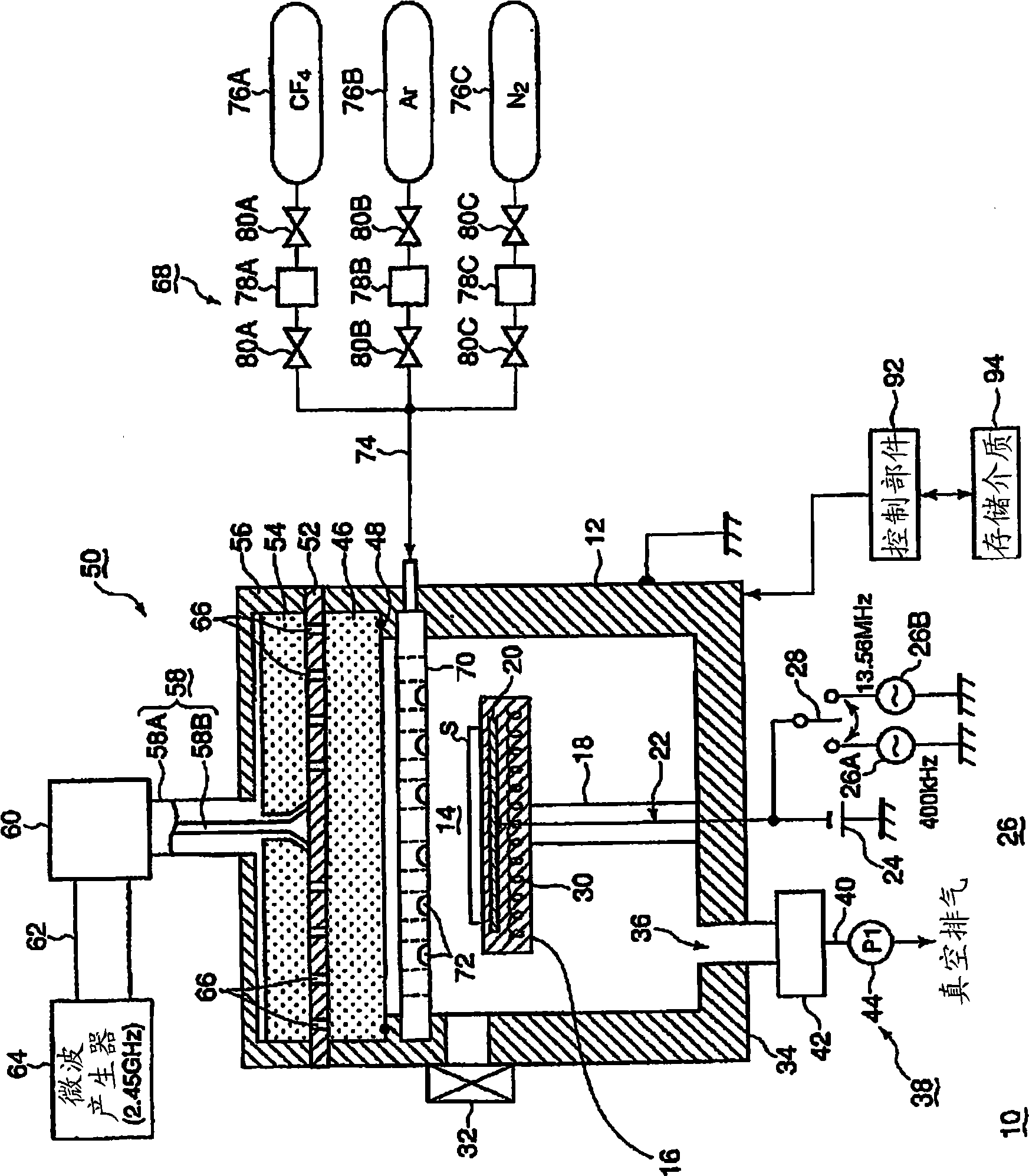

[0047] figure 1 It is a configuration diagram showing an example of the etching apparatus of the present invention. As shown in the figure, for example, the side wall and the bottom of the etching device 10 are made of conductors such as aluminum, and have a cylindrical processing container 12 formed as a whole. The inside of the etching device 10 is constituted as a closed processing space 14. Plasma is formed in the processing space 14 . The processing vessel 12 itself is grounded.

[0048] In the processing container 12 is accommodated a disc-shaped mounting table 16 on which an object to be processed, for example, a semiconductor wafer S is mounted on the upper surface. The mounting table 16 is formed in a flat substantially disc shape from ceramics such as alumina as a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com